Method for extracting hydroxytyrosol

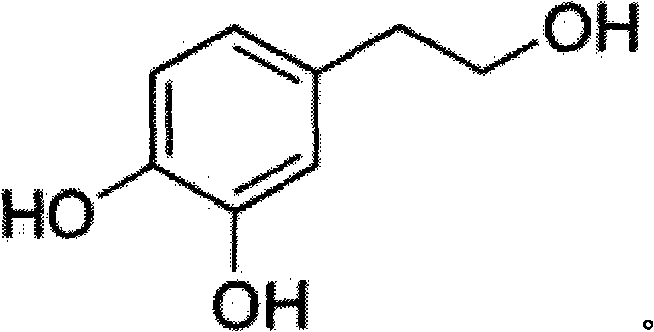

A technology of hydroxytyrosol and extraction method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of single raw material and low yield, improve conversion rate, save production cost, and shorten conversion the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of olive leaf extract

[0031] Use fresh olive leaves as raw materials, crush them into coarse powder, add water to decoct and extract twice (the amount of water added each time is 10 times the weight of the raw materials, and extract for 100 minutes each time), combine the decoction liquid, concentrate to the weight of the raw materials, and filter to obtain Olive Leaf Extract.

[0032]After determination, the content of iridoid glucoside oleuropein in the extract is 8%. The method of determination is (the same below): HPLC, chromatographic condition: chromatographic column (Kromasil 100-5C18); Mobile phase: acetonitrile: water=25: 75, ultraviolet detection wavelength: 285nm, column temperature: 27 ℃, flow velocity: 1mL / min).

[0033] 2. Preparation of hydroxytyrosol

[0034] 1) Take 1L of the above-mentioned extract as a raw material, add concentrated hydrochloric acid to make the pH value 1, boil for 3 hours, and enter the hydrolyzed solution into ...

Embodiment 2

[0037] 1. Preparation of Rhodiola rosea extract

[0038] Use Rhodiola rosea as the raw material, crush it to 100 mesh, add water to decoct and extract 3 times (add water 10 times the weight of the raw material for the first time, extract for 90 minutes, add water 6 times the weight of the raw material for the second time, extract for 30 minutes, and add water for the third time Extract with 6 times the weight of the raw material in water for 30 minutes), combine the decoction liquid, concentrate to the weight of the raw material, and filter to obtain the Rhodiola rosea extract.

[0039] After determination, the content of iridoid glucoside oleuropein in the Rhodiola daflora extract is 1.1%.

[0040] 2. Preparation of hydroxytyrosol

[0041] 1) Take 1L of the above-mentioned extract as a raw material, add concentrated hydrochloric acid to make the pH value 2, boil for 4 hours, adjust the pH value of the obtained hydrolyzate to 6.0 with sodium hydroxide, concentrate to the weig...

Embodiment 3

[0044] 1. Preparation of Japanese privet extract

[0045] Use the dried branches and leaves of Privet japonica as raw materials, crush them to 80 mesh, add 12 times the weight of raw materials to decoct and extract for 150 minutes, collect the decoction liquid, concentrate to the weight of raw materials, and filter to obtain Ligustrum chinensis extract liquid.

[0046] After determination, the content of iridoid glucoside oleuropein in the extract of Privet japonica is 0.8%.

[0047] 2. Preparation of hydroxytyrosol

[0048] 1) Take 1L of the above-mentioned extract as a raw material, add concentrated hydrochloric acid to make the pH value 1.5, boil for 2 hours, and enter the hydrolyzed solution into D101 macroporous adsorption resin column chromatography, collect the effluent, and use pH = 1.5 hydrochloric acid ( 3 times the volume of the resin column bed) to elute, combine the effluent and pickling solution, adjust the pH value to neutral with sodium hydroxide, concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com