Whole-core antiflaming conveyer belt with transition layer and production method thereof

A transitional layer and conveyor belt technology, applied in the direction of conveyors, layered products, transportation and packaging, etc., can solve the problems of high transportation efficiency, small conveying inclination, poor trough formation, etc., to improve production efficiency, prolong service life, The effect of high adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

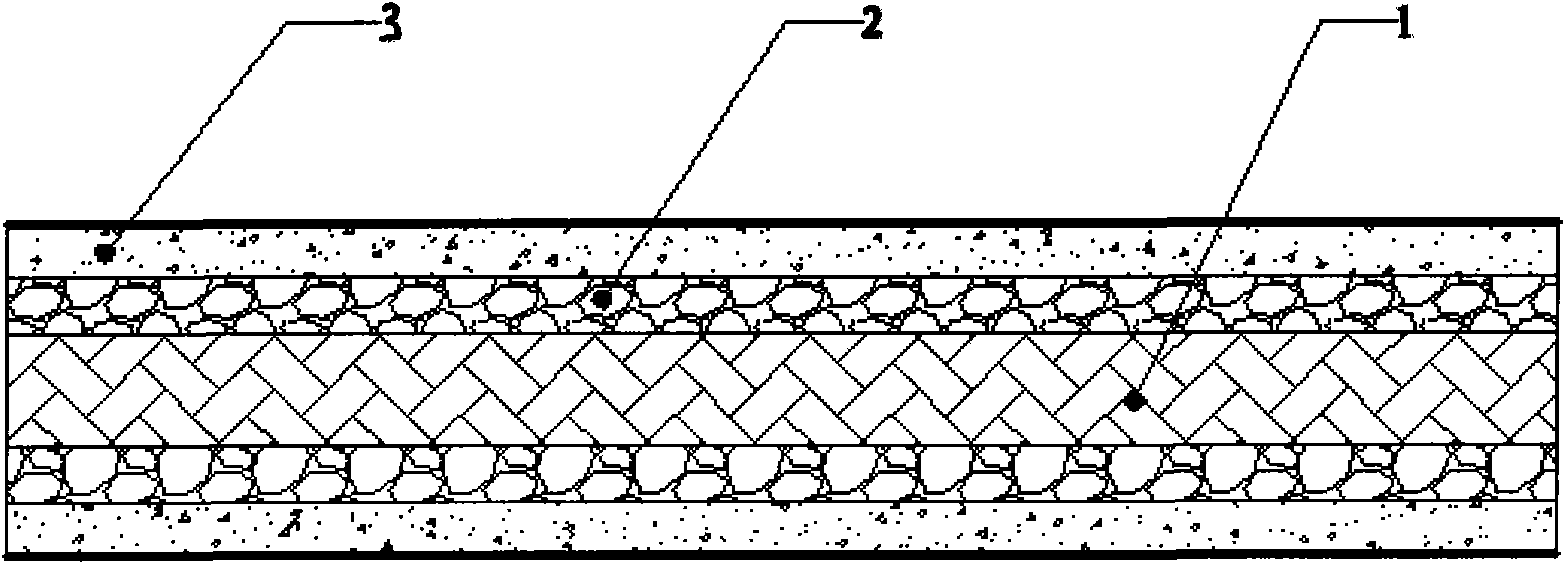

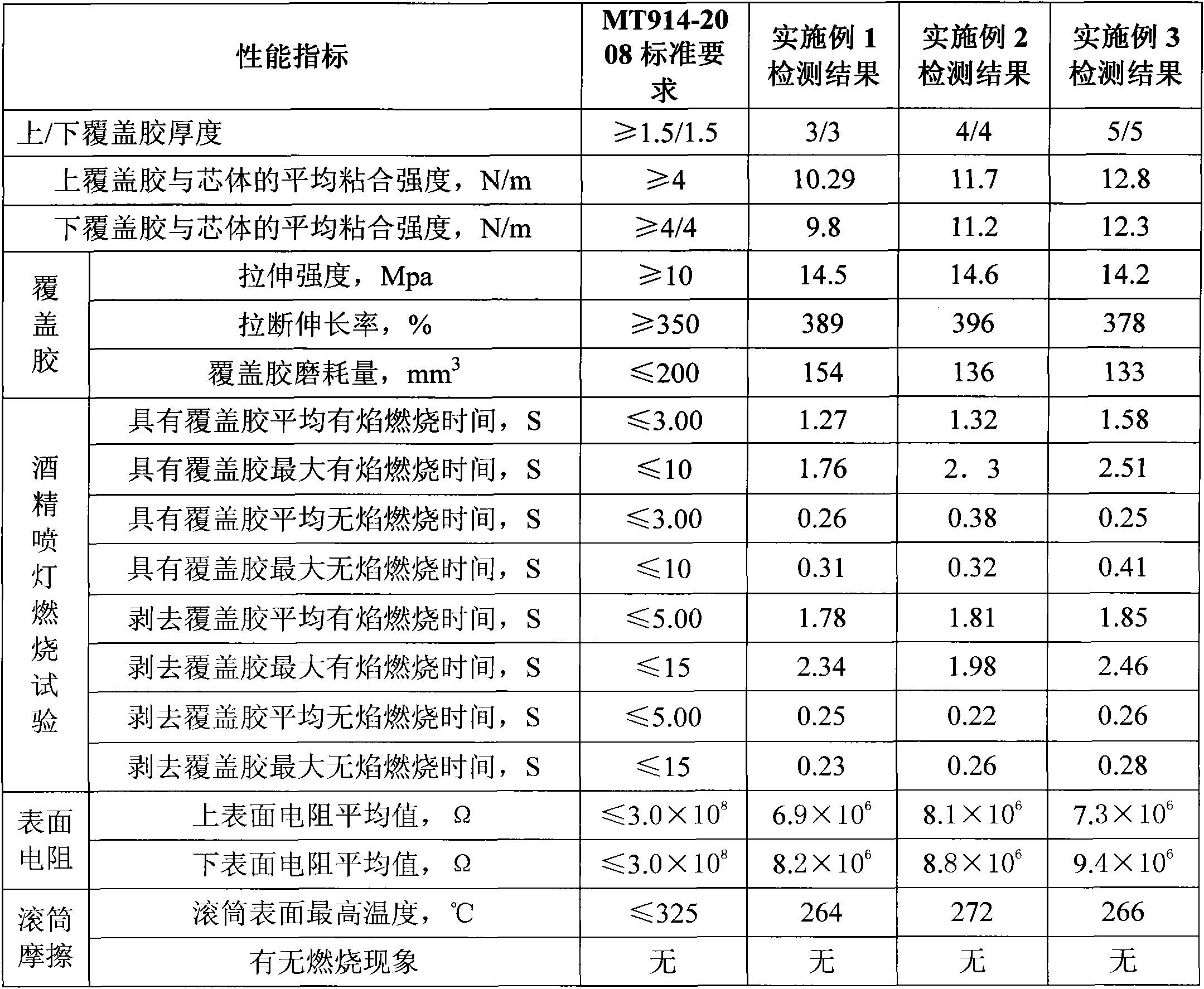

[0023] As shown in the drawings, the whole-core flame-retardant conveyor belt with a transition layer according to the present invention includes a skeleton material 1 , a transition layer 2 and a cover layer 3 . Skeleton material 1 is the dense whole of the fabric core after dipping and plasticizing. The core is made of cotton yarn and synthetic fiber (polyester, nylon) and then woven into three or more layers. The overall structure of the fabric; the transition layer 2 is a flame-retardant thermoplastic elastomer; the cover layer 3 is a flame-retardant and antistatic vulcanized rubber compound.

[0024] The production process is as follows: firstly, the whole fabric core is soaked and plasticized into a dense whole to obtain the skeleton material 1; the skeleton material is pasted together with the transition layer by two extruders in a hot state of 170-180°C ; Again, the pasted transition layer and skeleton material are in a hot state of 160-170 ° C, and then the covering l...

Embodiment 2

[0029] Product structure and production technology are with embodiment 1.

[0030] The thermoplastic elastomer is a blend comprising powdered nitrile rubber and polypropylene, and the blend formula is in parts by weight: 50 parts of powdered nitrile rubber, 50 parts of polypropylene, polypropylene malay Anhydride grafting reaction product (PP-g-MA) 5 parts, TDCPP 15 parts, flame retardant active magnesium hydroxide 40 parts, ammonium polyphosphate 30 parts, red phosphorus 10 parts, carbon black 12 parts, anti-aging agent A1 part, anti-aging 1 part of agent D, 4 parts of phenolic resin, and 0.5 part of stannous chloride. The preparation process is: first, polypropylene polypropylene, grafted reaction product with maleic anhydride (PP-g-MA), flame retardant plasticizer, flame retardant, carbon black, anti-aging agent, phenolic resin, stannous chloride After hot mixing and pre-plasticizing in a high-speed kneader, after cooling to room temperature, add powdered nitrile rubber an...

Embodiment 3

[0034] Product structure and production technology are with embodiment 1.

[0035] The thermoplastic elastomer is a blend comprising powdered nitrile rubber and polyvinyl chloride, and the blend formula is in parts by weight: 45 parts of powdered nitrile rubber, 55 parts of polyvinyl chloride, chlorinated 5 parts of paraffin, 10 parts of CDP, 10 parts of antimony trioxide, 10 parts of red phosphorus, 20 parts of zinc borate, 10 parts of decabromodiphenyl ether, 15 parts of carbon black, 5 parts of zinc oxide, 1 part of stearic acid, sulfur 1 part, 1 part of accelerator CZ, 0.5 part of TMTD, 1 part of tribasic lead sulfate, 1 part of dibasic lead phosphite, 1.5 parts of anti-aging agent RD. The preparation process is as follows: first, polyvinyl chloride, flame retardant plasticizer, flame retardant, carbon black, stearic acid, stabilizer, stearic acid, etc. are thermally mixed and preplasticized in a high-speed kneader, and then cooled to room temperature , then add powdered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com