Method for precisely grinding large-scale special type curved surface and grinding equipment thereof

A precision grinding and large-scale technology, which is applied in the direction of grinding/polishing equipment, spherical grinding machines, grinding machines, etc., can solve the problem of reducing the bearing load of the ball supporting the spindle system, etc., to improve the surface roughness of the ball, stable rotation, and dynamic performance improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

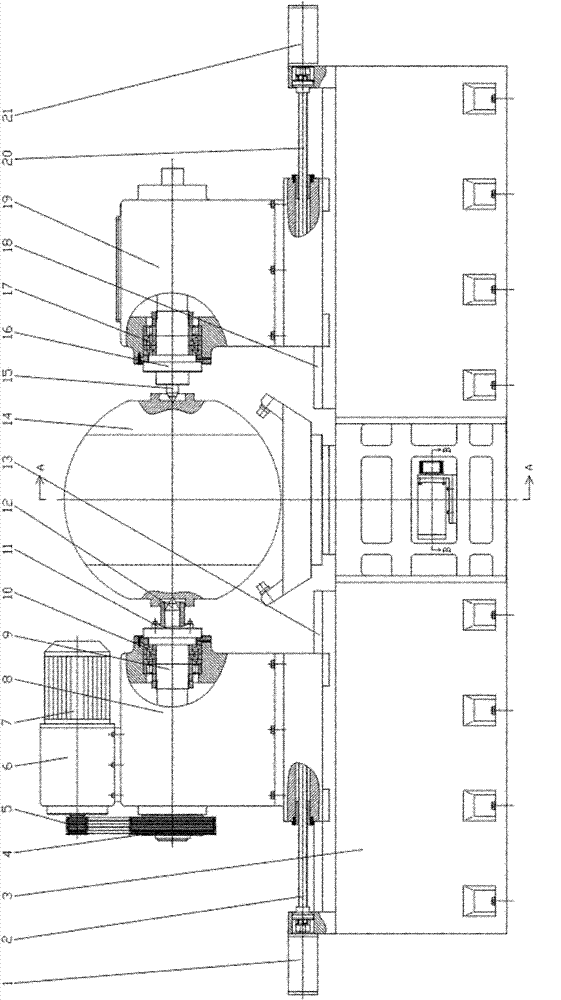

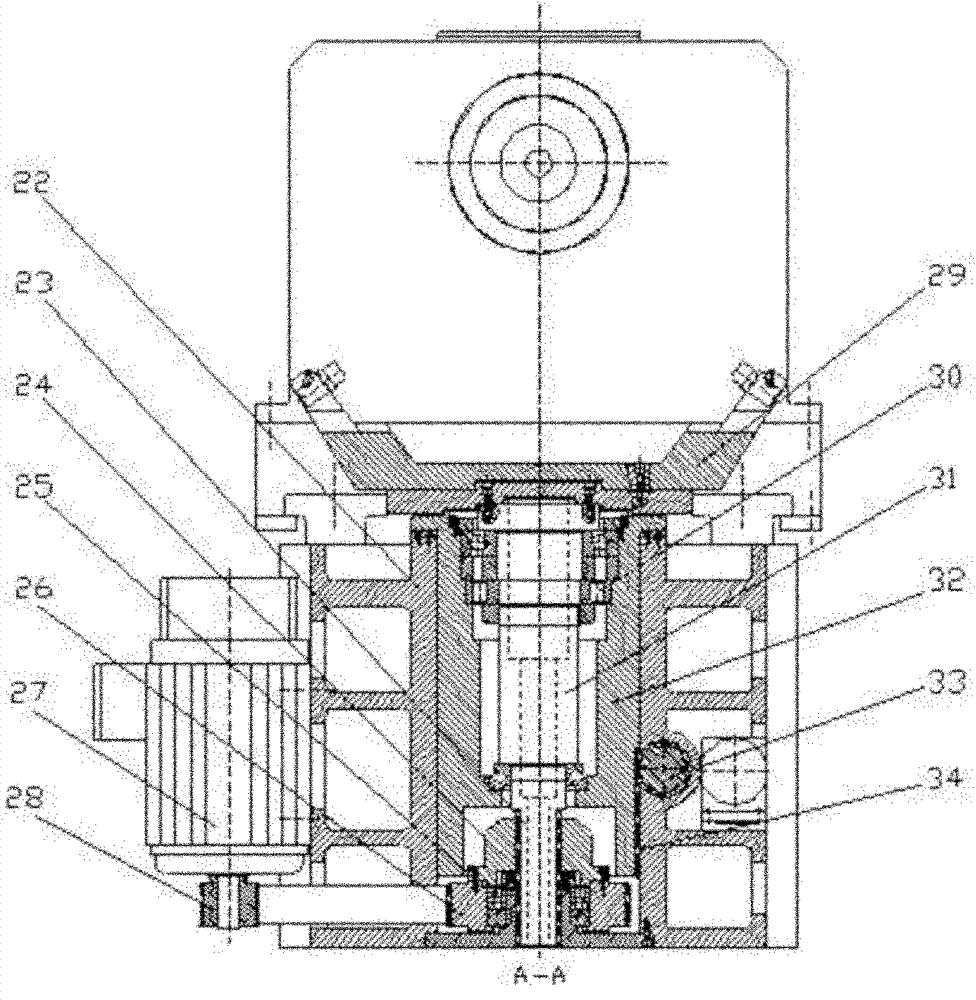

[0030] Such as Figure 1-Figure 3 As shown, this embodiment includes: a bed part a, a ball-supported spindle mechanism b, a ball-supported tailstock mechanism c, and a grinding wheel abrasive mechanism d, wherein: the ball-supported spindle mechanism b and the ball-supported tailstock mechanism c are respectively movable On both sides of the bed part a, the grinding wheel mechanism d is installed in the middle of the bed part a.

[0031]The bed part a includes: a bed 3, a grinding wheel and a grinding tool system mounting seat, two sliding linear guide rails and their corresponding two sets of screw nut pairs and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com