Double reverse flotation process of middle-low grade phosphorite

A phosphorite and double reverse flotation technology, applied in flotation, solid separation, etc., can solve the problems of poor selectivity, lower flotation separation efficiency, deterioration of flotation process, etc., and achieve easy control and operation, desiliconization and reverse flotation Simple and smooth selection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

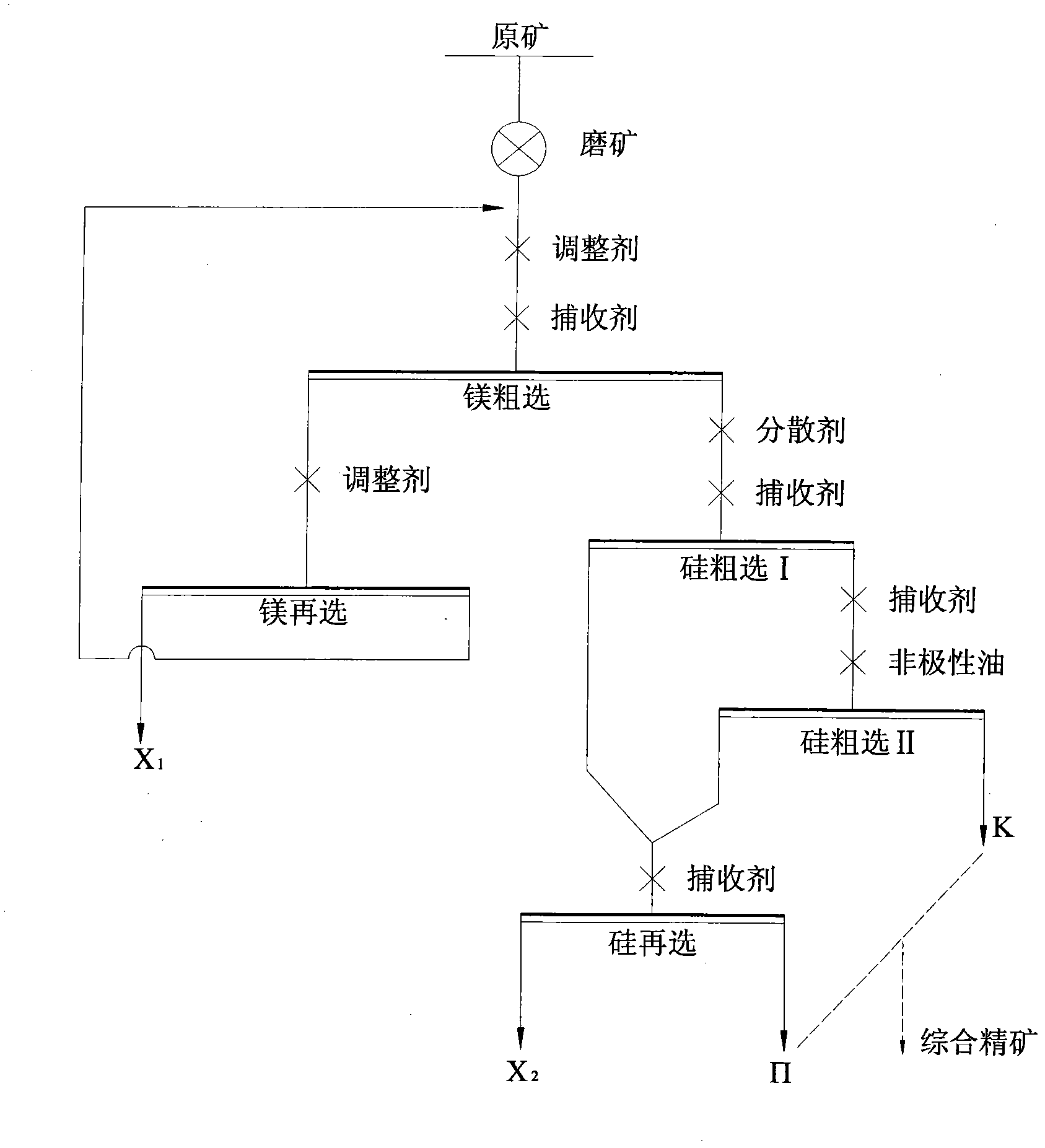

[0014] Example 1. refer to figure 1 . A double reverse flotation process for medium and low-grade phosphorite, the steps of which are:

[0015] (1) After the phosphorite raw ore is ground to the particle size required by flotation, add reverse flotation magnesium removal regulator 5kg / t raw ore and magnesium removal collector 0.8kg / t raw ore to carry out magnesium roughing operation, magnesium roughing The tank contains coarse concentrate for magnesium removal; magnesium roughing foam is added with 1kg / t raw ore regulator to carry out magnesium re-election operation, and the magnesium re-election tank is for magnesium-removing medium ore, and the magnesium-removing medium ore returns to magnesium roughing in sequence. The magnesium re-election foam is carbonate tailings; the magnesium roughing flotation time is 5 minutes, and the magnesium re-election time is 4 minutes; the magnesium removal regulator is selected from sulfuric acid, phosphoric acid or sulfuric acid and phosp...

Embodiment 2

[0017] Example 2. refer to figure 1 . A double reverse flotation process for medium and low-grade phosphorite, the steps of which are:

[0018] (1) After the phosphorite raw ore is ground to the particle size required by flotation, 15kg / t of reverse flotation magnesium removal regulator and 2.5kg / t raw ore of magnesium removal collector are added to carry out magnesium roughing operation. The tank contains coarse concentrate for magnesium removal; magnesium roughing foam is added with 0.1kg / t raw ore regulator to carry out magnesium re-election operation, and the magnesium re-election tank is for magnesium-removing medium ore, and magnesium-removing medium ore returns to magnesium roughing in sequence The magnesium re-election foam is carbonate tailings; the magnesium roughing flotation time is 8 minutes, and the magnesium re-election time is 6 minutes; the magnesium removal regulator is selected from sulfuric acid, phosphoric acid or sulfuric acid and phosphoric acid in a m...

Embodiment 3

[0020] Example 3. refer to figure 1 . A double reverse flotation process for medium and low-grade phosphorite, the steps of which are:

[0021] (1) After the phosphorite raw ore is ground to the particle size required by flotation, add 10kg / t raw ore of reverse flotation magnesium removal regulator and 1.5kg / t raw ore of magnesium removal collector to carry out magnesium roughing operation, magnesium roughing The tank contains coarse ore for magnesium removal; the magnesium roughing foam is added with 0.5kg / t raw ore regulator, and the magnesium re-election operation is carried out. The magnesium re-election foam is carbonate tailings; the magnesium roughing flotation time is 6 minutes, and the magnesium re-election time is 5 minutes; the magnesium removal regulator is selected from sulfuric acid, phosphoric acid or sulfuric acid and phosphoric acid in a mass ratio of 1: 1, the magnesium removal collector is a saponified product of alkyl fatty acid;

[0022] (2) Add 200g / t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com