Method for preparing nanoliposomes by supercritical CO2 fluid

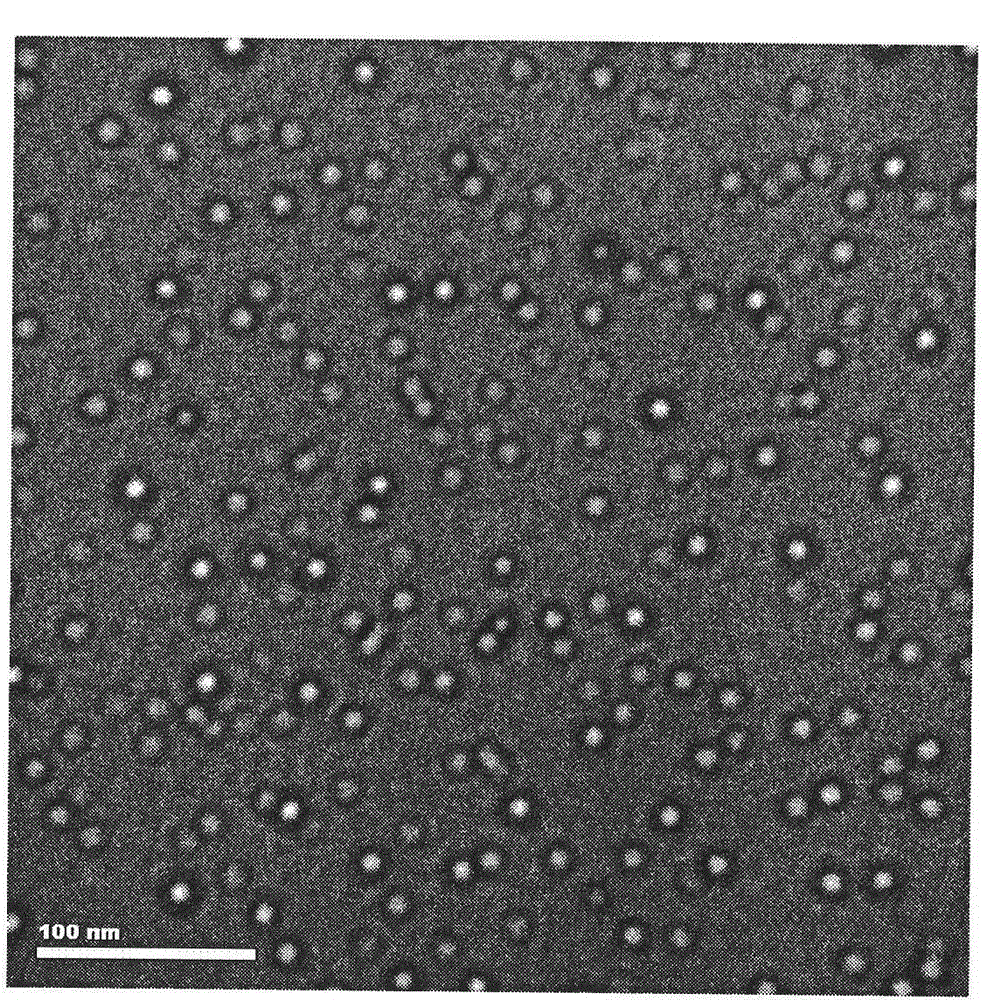

A nano-liposome and supercritical technology, which is applied in the direction of liposome transportation, can solve the problems of limited compatibility and other problems, and achieve the effect of good affinity, uniform particle size distribution and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation and determination of embodiment 1 nano liposome

[0030] 1. Preparation of Nanoliposomes

[0031] Phosphatidylcholine, provided by Shanghai Bioengineering Company;

[0032] Experimental device: Jiangsu Hua'an supercritical reaction device, in which the rapid expansion part is designed and manufactured by the Modern Technology Center of South China University of Technology. The capacity of the reactor is 1L, the capacity of the collection tank is 2L, the maximum pressure is 35MPa, and the maximum temperature is 368K.

[0033] Preparation method: In one embodiment, the method for preparing nanoliposomes of the present invention can be carried out in supercritical CO 2 Completed in the reaction device, the flow chart is as follows figure 1 shown. The specific steps are: mix 22g of phosphatidylcholine [x(PC)=1.7×10 -3 ] dissolved in 150mL ethanol [x(CH 3 CH 2 OH)=1.5×10 -1 ], inject CO 2 In the fluid reaction kettle 6, inject 500 mL of PBS buffer solutio...

Embodiment 2

[0038] The impact of embodiment 2 phospholipid dosage on liposome formation

[0039] This embodiment investigates and forms the required phospholipid consumption of microemulsion [phospholipid is in supercritical CO 2 Effect of mole fraction, x(PC)] on the formation of nanoliposomes. Control x(PC) is 3.8×10 -4 ~2.3×10 -3 , the amount of ethanol and water is set to x(CH 3 CH 2 OH)=1.5×10 -1 with x(H 2 O)=1.5×10 -1 , at a pre-expansion pressure of 25MPa and a pre-expansion temperature of 333K for 2h. The formed supercritical microemulsion was sprayed into the buffer solution at 2L / min, and the prepared liposome suspension was collected. According to the method and parameters of Example 1, the average particle size and particle size distribution of the prepared liposomes were measured, and the results are shown in Table 1.

[0040] The influence of table 1 phospholipid dosage on nano liposome preparation

[0041]

[0042] The results of this example show that when ...

Embodiment 3

[0043] The influence of embodiment 3 distilled water consumption on liposome formation

[0044] This example examines the amount of water required to form a microemulsion [x(H 2 O)] on liposome formation. Control x(PC)=1.7×10 -4 , the amount of ethanol is x(CH 3 CH 2 OH)=1.5×10 -1 , the amount of distilled water x(H 2 O) is 0~3.1×10 -1 , at a pre-expansion pressure of 25MPa and a pre-expansion temperature of 333K for 2h. Formation of supercritical microemulsion CO 2 Spray into the buffer solution at a speed of 2L / min, and collect the prepared liposome suspension. According to the method and parameters of Example 1, the average particle size and particle size distribution of the prepared liposomes were measured, and the results are shown in Table 2.

[0045] The impact of the amount of water required for the formation of table 2 microemulsions on the preparation of nanoliposomes

[0046]

[0047] The results of this example show that distilled water can 2 The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com