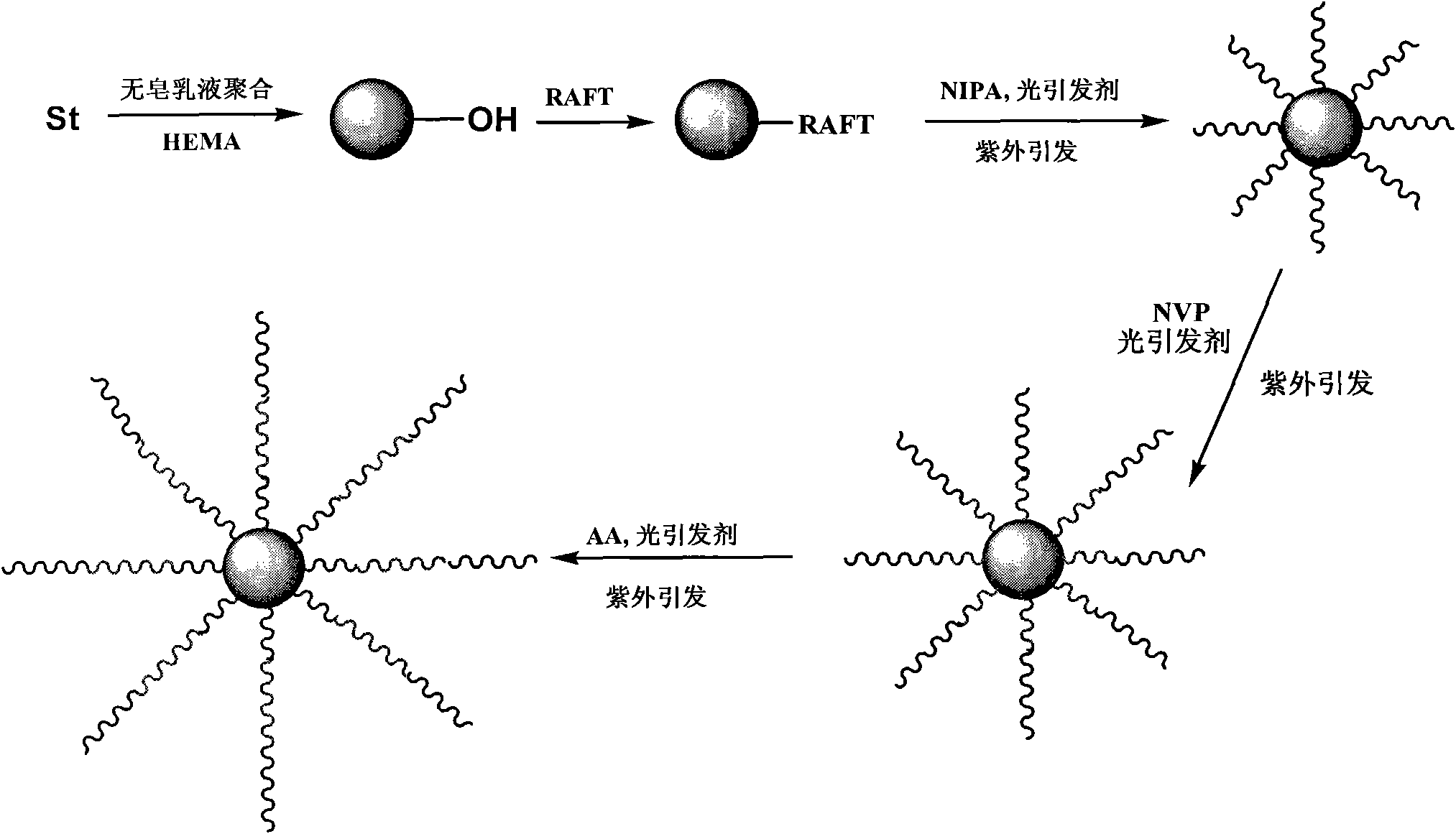

Methods for preparing multiple environment-responding type hairy polymer micro-spheres and photo-initiation RAFT (Reversible Addition-Fragmentation chain Transfer) polymerization thereof

An environment-responsive, polymer technology, which is applied in the field of preparation of multiple environment-responsive hair-like polymer microspheres and photo-initiated RAFT polymerization, can solve the unpublished preparation of environment-responsive hair-like polymer microspheres, and achieve The effects of expanding controllability, controllable structure, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] step 1)

[0037] In a 1000ml reaction kettle equipped with a condenser tube, a thermometer and a mechanical stirrer, nitrogen was passed for 10 minutes in advance, and then 720gH 2 O, 180g styrene (St), 1.8g NaHCO 3 And 1.8gNaOH, nitrogen protection, treat that system temperature reaches 60 ℃, add 0.648g potassium persulfate (KPS) in the system as initiator (by mass ratio, H 2 O:St:NaHCO 3 : NaOH: KPS is 4: 1: 0.01: 0.01: 0.0036), after reacting for 8 hours, 1.8 g of hydroxyethyl methacrylate was added dropwise (by mass ratio, hydroxyethyl methacrylate: St was 0.01: 1), The dropwise addition time was 2 hours to obtain polystyrene (PS) microspheres with a particle diameter of 900 nm and hydroxyethyl methacrylate supported on the surface. Centrifuge the prepared microspheres in a high-speed refrigerated centrifuge for 15 minutes at a speed of 6000 rpm, then wash the obtained microspheres with deionized water, repeat the centrifugation and washing three times, and obtai...

Embodiment 2

[0043] step 1)

[0044] In a 1000ml reaction kettle equipped with a condenser tube, a thermometer and a mechanical stirrer, nitrogen was passed for 10 minutes in advance, and then 720gH 2 O, 7.2gSt, 3.6g divinylbenzene (DVB), 0.0144g KHCO 3 And 0.0144gKOH, nitrogen protection, treat that system temperature reaches 90 ℃, add 0.648gKPS in the system as initiator (according to mass ratio, H 2 O:St:DVB:NaHCO 3 : NaOH: KPS is 100: 1: 0.5: 0.002: 0.002: 0.09), after reacting for 1h, 0.72g hydroxypropyl methacrylate was added dropwise (by mass ratio, hydroxypropyl methacrylate: St was 0.1: 1 ), and the dropping time was 3h to obtain cross-linked PS microspheres with a particle size of 100nm and surface loading of hydroxypropyl methacrylate. Centrifuge the prepared microspheres in a high-speed refrigerated centrifuge for 15 minutes at a speed of 12,000 rpm, then wash the obtained microspheres with deionized water, and repeat the centrifugation and washing three times in this way to...

Embodiment 3

[0050] step 1)

[0051] In a 1000ml reaction kettle equipped with a condenser tube, a thermometer and a mechanical stirrer, nitrogen was passed for 10 minutes in advance, and then 720gH 2 O, 36gSt, 1.8g ethylene glycol dimethacrylate (EGDMA), 0.0144gNH 4 HCO 3 and 0.051 g of 28% NH 3 ·H 2 O, under nitrogen protection, when the temperature of the system reaches 80°C, add 0.72gKPS and 0.72g ammonium persulfate (APS) to the system as the initiator (by mass ratio, H 2 O:St:EGDMA:NH 4 HCO 3 : NH 3 ·H 2 O: KPS: APS is 20: 1: 0.05: 0.0004: 0.0004: 0.02: 0.02), after reacting for 5h, 10.8g of hydroxyisopropyl methacrylate was added dropwise (by mass ratio, hydroxyisopropyl methacrylate: St is 0.3:1), and the dropping time is 5 hours to obtain cross-linked PS microspheres with a particle size of 400 nm and surface-loaded hydroxyisopropyl methacrylate. Centrifuge the prepared microspheres in a high-speed refrigerated centrifuge for 15 minutes at a speed of 9500 rpm, then wash t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com