Method for preparing high-solid-content and low-viscosity suspended nano calcium carbonate slurry and re-suspended nano calcium carbonate power

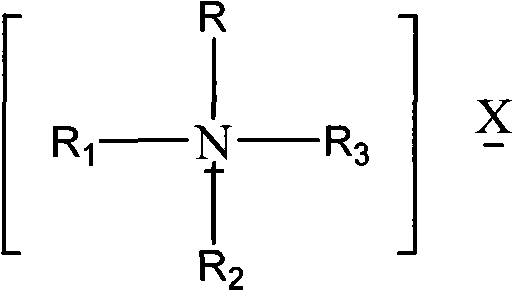

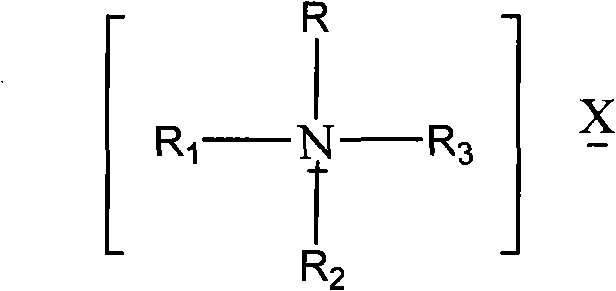

A technology of nano-calcium carbonate and high solid content, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of inconvenient transportation and storage, no dispersion of nano-calcium carbonate cations, etc., and achieve convenient transportation, reduced dosage, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 240mL of water in a beaker, preheat it in a constant temperature water bath at 70°C and electric stirring, add 3.0g of cetyltrimethylammonium bromide and polydiallyldimethylammonium chloride to the water (5:1 mass ratio) mixed dispersant, 0.5g polyethylene glycol 20000 and sodium hydroxymethyl cellulose (1:1) mixed dispersant stirred for 5min, took by weighing 60g active nano-calcium carbonate, under the situation of stirring Slowly add water, if there are bubbles, add a few drops of tributyl phosphate defoamer, and continue stirring for 10 minutes to obtain a cation-dispersed nano-calcium carbonate suspension slurry with a solid content of 20%.

Embodiment 2

[0038] Put 210mL of water in a beaker, preheat it in a constant temperature water bath at 70°C and electric stirring, add 3.6g of dodecyltrimethylammonium bromide and polyethyleneimine (5:1) to the water to mix and disperse dispersant, 0.8g polyethylene glycol 20000 and polyvinyl alcohol 500 (3:1) mixed dispersant and stirred for 5 minutes, weighed 90g active nano-calcium carbonate, slowly added to water while stirring again, if there are bubbles, add a few drops of phosphoric acid Tributyl ester defoamer, continue to stir for 10 minutes to obtain a cation-dispersed nano-calcium carbonate suspension slurry with a solid content of 30%.

Embodiment 3

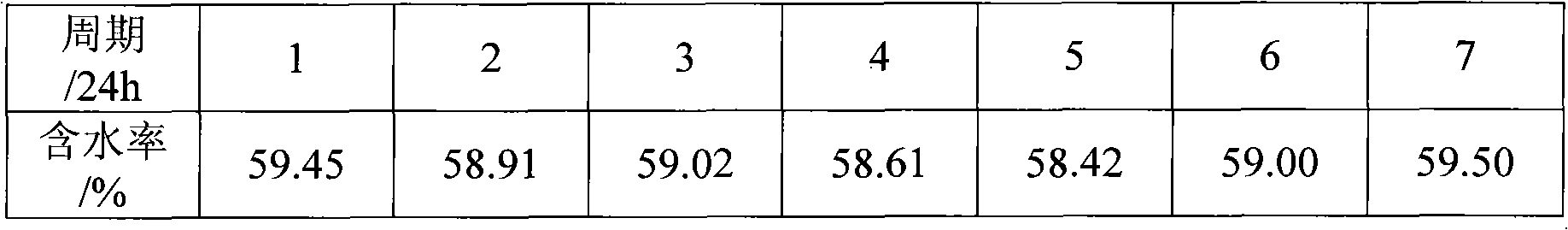

[0040] Put 150mL of water in a beaker, preheat it in a constant temperature water bath at 70°C and electric stirring, add 6g of tributylmethylammonium chloride and dodecyltrimethylammonium chloride (1:5) into the water to mix and disperse After stirring 1.5g of polyethylene glycol 20000 for 5 minutes, weigh 150g of active nano-calcium carbonate, slowly add it into water while stirring, if there are bubbles, add a few drops of tributyl phosphate defoamer, and continue stirring for 10 minutes to get The cation-dispersed nano-calcium carbonate slurry with 50% solid content is diluted with water to the suspension slurry with 30% solid content, and it is allowed to stand for 24 hours without delamination or sedimentation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com