Manufacturing method of steel tubeless wheels for vehicles

A production method and steel technology, applied in metal processing equipment and other directions, can solve problems such as material waste, and achieve the effects of less equipment investment, good product balance performance, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiment, referring to the accompanying drawings, a method for manufacturing a steel tubeless wheel for automobiles of the present invention comprises the following steps:

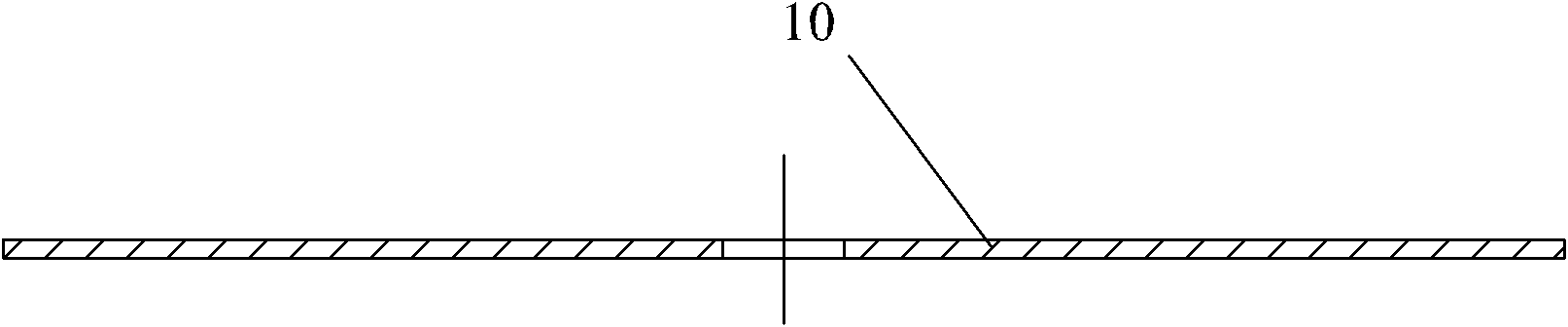

[0024] A. A piece of steel plate with a certain thickness is made into an annular blank plate 10 with a circular hole in the middle (such as figure 1 shown);

[0025] There is a through hole in the middle of the annular blank plate 10;

[0026] The size of the annulus of the annular blank plate 10 is calculated according to the weight of the required product;

[0027] The thickness of the steel plate is also determined according to the needs of the product;

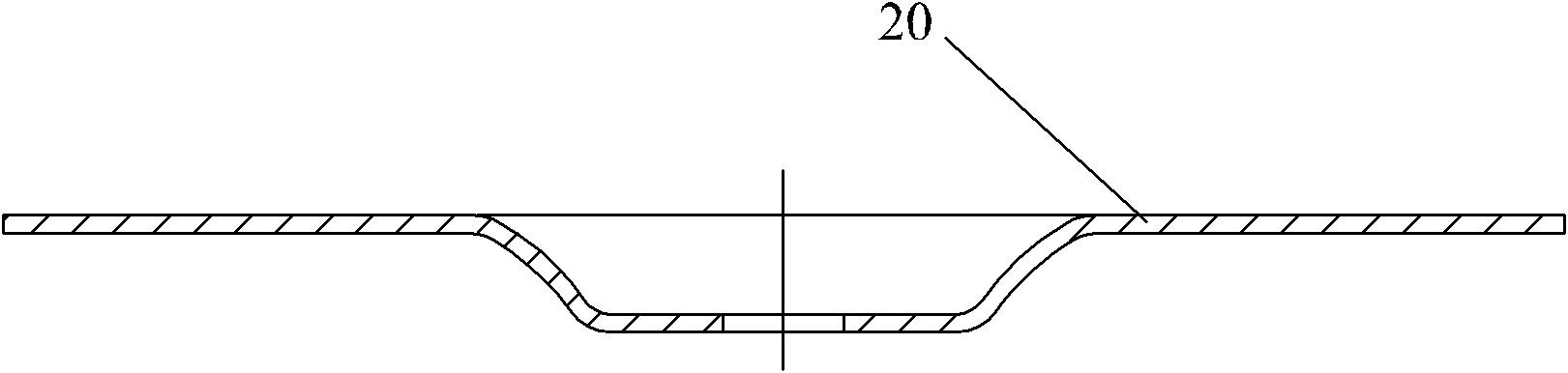

[0028] B. Carry out the mold pressing process for the first time: press this annular blank plate 10 into the hat shape blank plate 20 (as figure 2 shown);

[0029] The first mold can have a convex shape in the middle, or a concave shape in the middle; for different mold shapes, different force directions can be used for the annular blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com