Lubricant composition for fine blanking

A lubricating oil composition, precision blanking technology, applied in the direction of lubricating composition, additives, petroleum industry, etc., can solve the problems of safety, air pollution, etc., and achieve the effect of fully saving energy and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

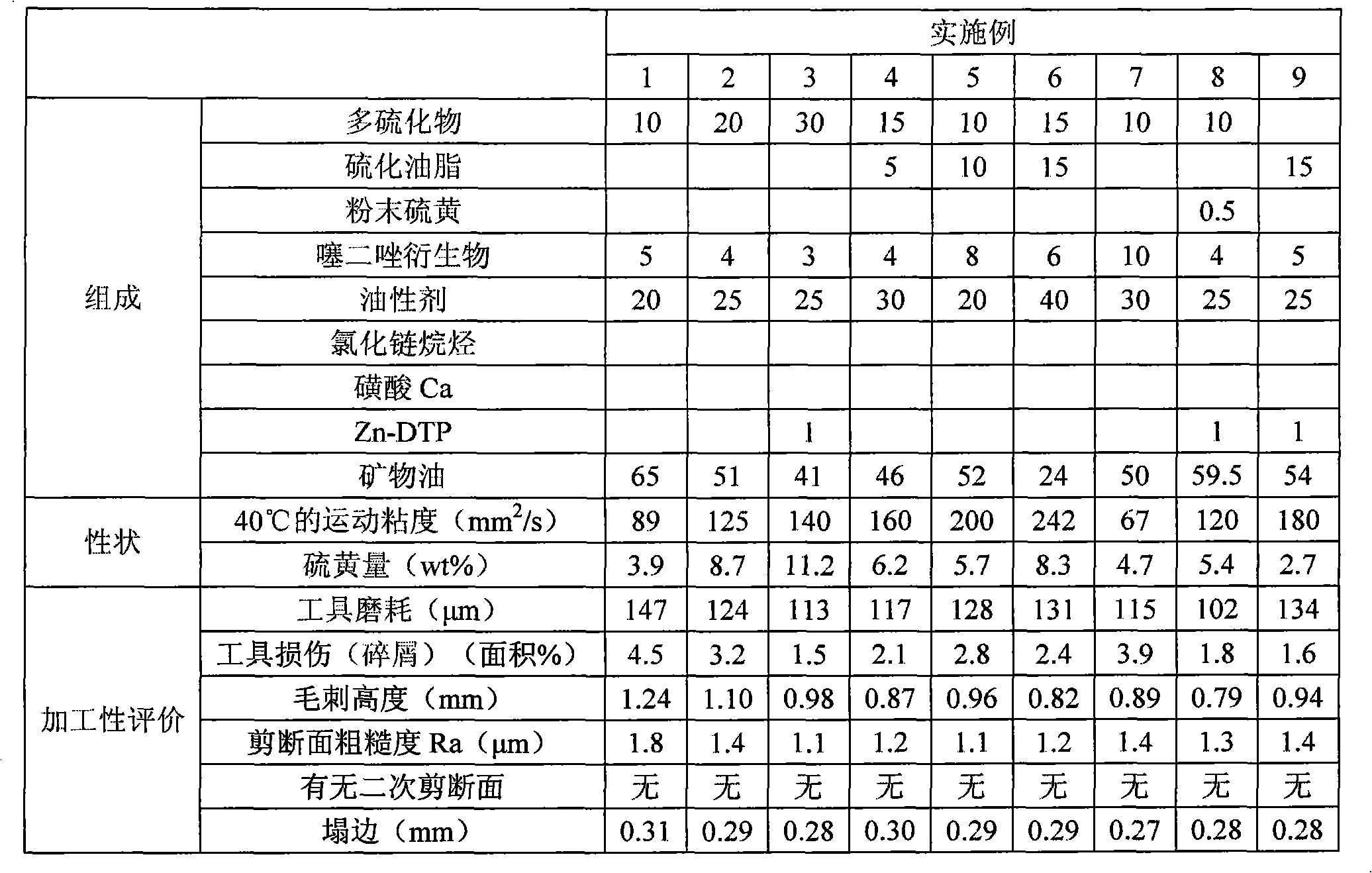

[0088] Mix the above polysulfides, thiadiazole derivatives, oily agents, and mineral oil in the amounts shown in Table 1-1 to obtain a kinematic viscosity of 89mm at 40°C 2 / s lubricating oil. With respect to the lubricating oil obtained, each processability was evaluated by the method mentioned above. The results are shown in Table 1-1.

Embodiment 2~9

[0090] In Example 1, lubricating oils having kinematic viscosities shown in Table 1-1 were obtained in the same manner except that the lubricating oil compositions were as shown in Table 1-1. Each of the lubricating oils obtained was subjected to the same processing performance evaluation as in Example 1, and the results are shown in Table 1-1.

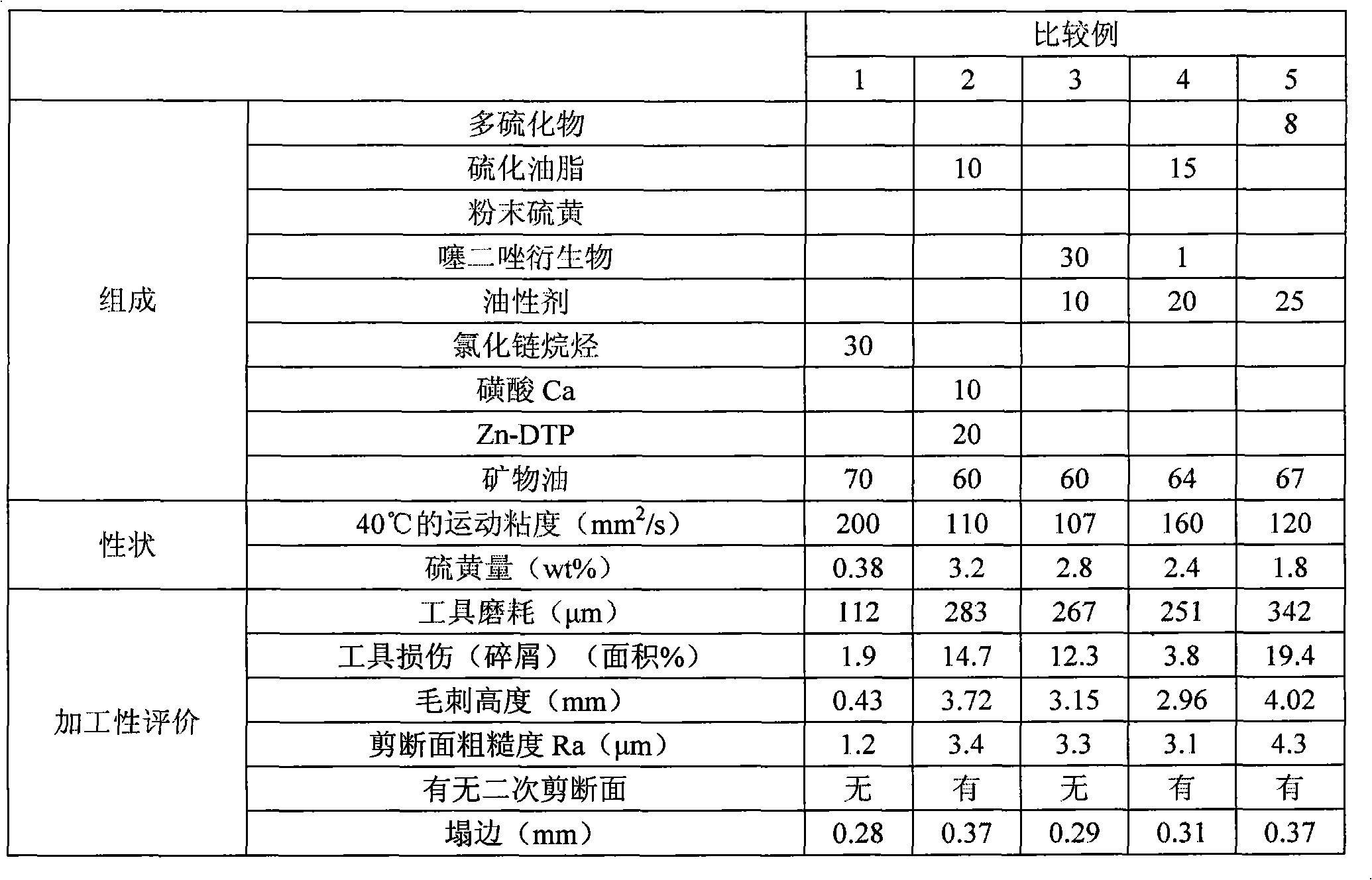

[0091] Table 1-1

[0092]

Embodiment 4

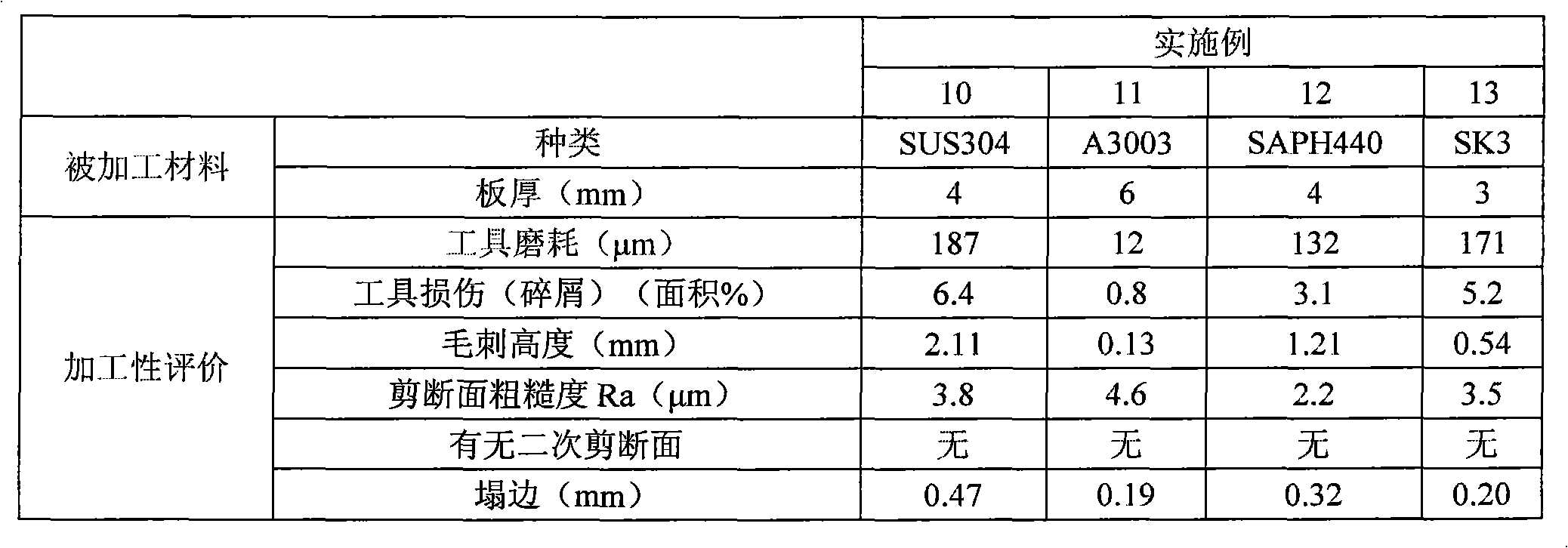

[0100] In Example 4, except that the processed material was replaced with those shown in Table 2, the same processing performance evaluation was performed, and the results are shown in Table 2.

[0101] Table 2

[0102]

[0103] From the above results, it can be seen that the present invention has almost the same excellent processing performance as chlorine-based processing oils regardless of the workpiece, and can perform environmentally friendly production without deteriorating the working environment or generating odors.

[0104] In addition, it is possible to achieve low viscosity with almost the same performance as chlorine-based processing oil, and it is possible to save energy such as power consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com