Control method for improving angular-displacement accuracy of rotary-table bearing

A technology of turntable bearing and control method, applied in the directions of bearing components, shafts and bearings, bearing assembly, etc., to achieve the effects of high measurement accuracy, change of system errors, and easy monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

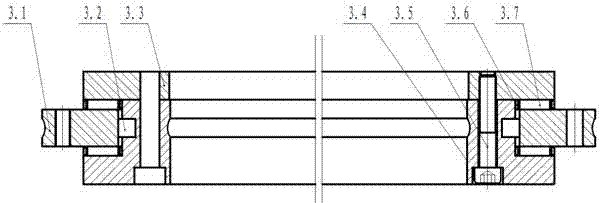

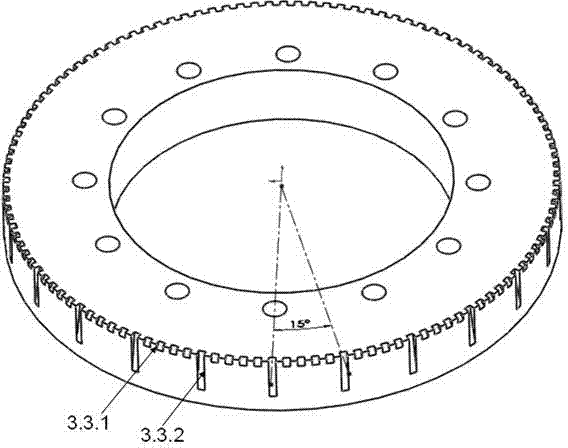

[0039] combine figure 2 , the present invention is used to improve the control method of the angular displacement accuracy of the turntable bearing, the said turntable bearing 3 includes the outer ring 3.1, the radial roller 3.2, the shaft ring 3.3, the inner ring 3.4, the connecting bolt 3.5, the cage 3.6 and the shaft To thrust cylindrical roller 3.7.

[0040]The outer ring 3.1 of the turntable bearing 3 is fixed, and the inner hole of the inner ring 3.4 and the shaft ring 3.3 is equipped with a worm gear device, and the worm gear device is connected with a servo motor or a stepping motor. When the servo motor or stepping motor is energized and working, the servo motor or stepping motor drives the worm gear device, and the worm gear device drives the shaft ring 3.3 to rotate and generate angular displacement. This transmission process is defined as an open-loop control method. The ring control method reduces the accuracy of the rotational angular displacement of the shaft r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com