Epitaxial material stress control-based GaN thick film self-separation method

An epitaxial material and stress control technology, applied in the field of material stress control and epitaxial growth, can solve the problems that the substrate cannot be reused and the process is complicated, and achieve good usability and controllability, and the effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

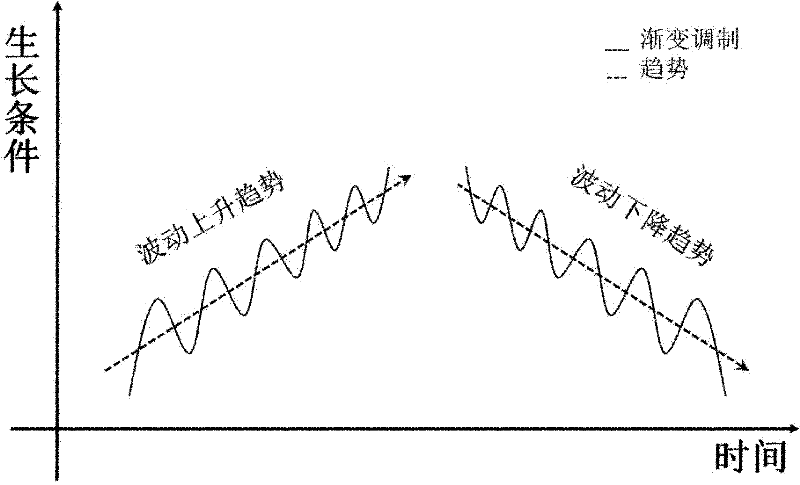

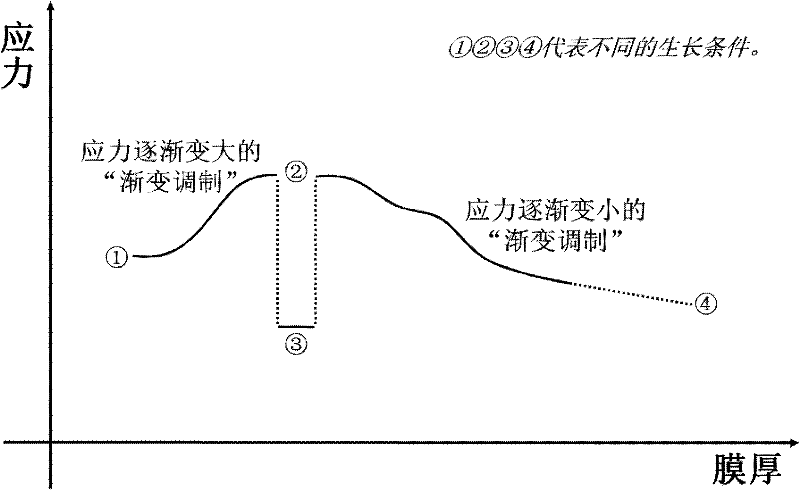

[0036] GaN thick film self-separation design scheme such as image 3 As shown, the growth window of stress distribution controlled by gradient modulation and jump modulation adopted in the embodiment of the present invention is: temperature 900°C-1100°C, pressure 100torr-650torr, ratio of 5-3 to 10-100, carrier gas is a mixture of hydrogen and nitrogen gas. The specific implementation is as follows:

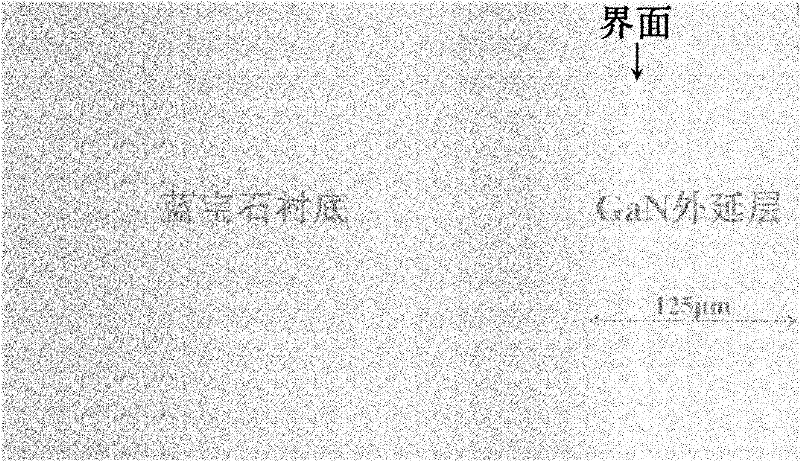

[0037] 1. Before growth, put the sapphire substrate in acetone, alcohol and deionized water for ten minutes, and then dry the substrate with a nitrogen gun and put it into the reaction chamber.

[0038] 2. During growth, firstly, hydrogen gas is introduced into the reaction chamber at high temperature to treat the sapphire substrate to remove the adsorbate on its surface.

[0039] 3. After that, the sapphire substrate is nitrided with ammonia gas at high temperature, and then the growth of GaN single crystal material starts.

[0040] 4. According to image 3 The first stage of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com