Cheese and preparation method thereof

A cheese and material liquid technology, applied in the field of fresh cheese and its production, can solve the problem that the natural cheese smell is not suitable for the taste of most Chinese people, and achieve the effect of non-irritating taste and strong aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

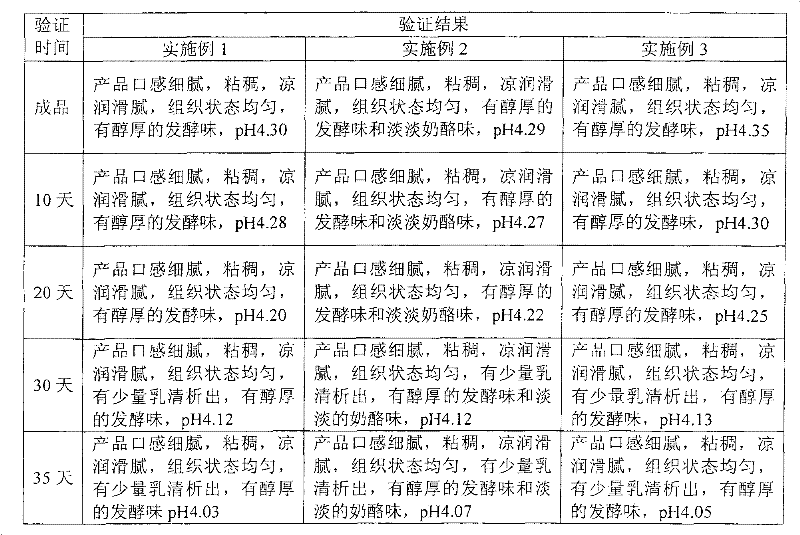

Embodiment 1

[0042] The process of making cheese in this embodiment mainly includes: raw milk inspection, standardization→ingredients→preheating→homogenization→sterilization→cooling→inoculation→stirring→insulation and fermentation→stirring and demulsification→refinement system→cooling→filling→refrigeration . The specific production method is as follows:

[0043] 1. Raw milk inspection: Standardize the milk that has passed the inspection and is free of antibiotics;

[0044] 2. Ingredients: white sugar 7%, whole milk powder 1.5%, anhydrous butter 3%, concentrated whey protein powder (80% protein) 4%, gelatin 0.7%, pectin 0.08%, emulsifier (propylene glycol fatty acid Esters) 0.1%, corn modified starch 0.5% and the weight ratio of the milk balance, the standardized milk is heated up to 50-60 ° C, the mixture of sugar, stabilizer and shear-resistant raw materials is added to the feed liquid, anhydrous Butter, at the same time turn on the high-speed emulsification pump, stir, and emulsify for...

Embodiment 2

[0055] In the present embodiment, the batching composition is: white granulated sugar 5%, aspartame 0.01%, whole milk powder 3%, anhydrous cream 4%, whey protein powder 5% (80% albumen), cheese powder 0.5%, 0.08% pectin, 0.2% propylene glycol fatty acid ester, 0.4% corn starch, 0.1% dietary fiber, the rest of milk; the milk fat content in the prepared feed liquid is about 7.5%, the milk protein content is about 7.2%, and the total solid content About 28.2%; the feed liquid is cooled to 29°C after being homogenized (65°C, 20MPa) and sterilized, and 0.01% starter (same as Example 1) and 0.001% rennet are added by weight of the feed liquid, and the fermentation is carried out for 18 After an hour, the pH of the feed liquid was detected to be about 4.3, stirred to break the emulsion, and refined (29°C, 0MPa homogeneous), cooled to below 20°C, filled, and the finished cheese of this embodiment was obtained. The process conditions not mentioned in detail in this embodiment are basic...

Embodiment 3

[0057] In the present embodiment, the batching composition is: white granulated sugar 7%, skimmed milk powder 3%, anhydrous cream 5%, whey protein powder 3% (80% albumen), soybean protein powder 0.5%, gelatin 0.5%, propylene glycol fatty acid 0.1% ester, 0.3% potato starch, 0.2% dietary fiber, and the rest of milk; the milk fat content in the prepared feed liquid is about 7.7%, the milk protein content is about 5.6%, and the total solid content is about 29.3%; After homogenization and sterilization, cool to 30°C, add 0.005% starter by feed liquid weight (purchased from CHR-HANSEN, containing about 1:1 Lactococcus lactis subsp. strain)), 0.001% rennet and 0.001% lipase, heat preservation and fermentation for 20 hours, detect the pH of the feed liquid is about 4.35, stir and break the emulsion, and refine (make the material pass through the pipeline installed with the refiner, the fine The refining device can be composed of multiple holes of 1.5-2 mm, and the inner surface of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com