Oxygen combustion boiler and pulverized coal burner

A technology of pulverized coal burner and oxy-combustion boiler, which is applied to the burner, burner, combustion air/fuel supply and other directions of burning powder fuel, can solve the problem of abnormally high temperature of oxygen nozzle and pulverized coal burner, pulverized coal burner, etc. Uneven combustion, inability to fully mix oxygen and pulverized coal, etc., to achieve the effect of inhibiting high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described below with reference to the drawings.

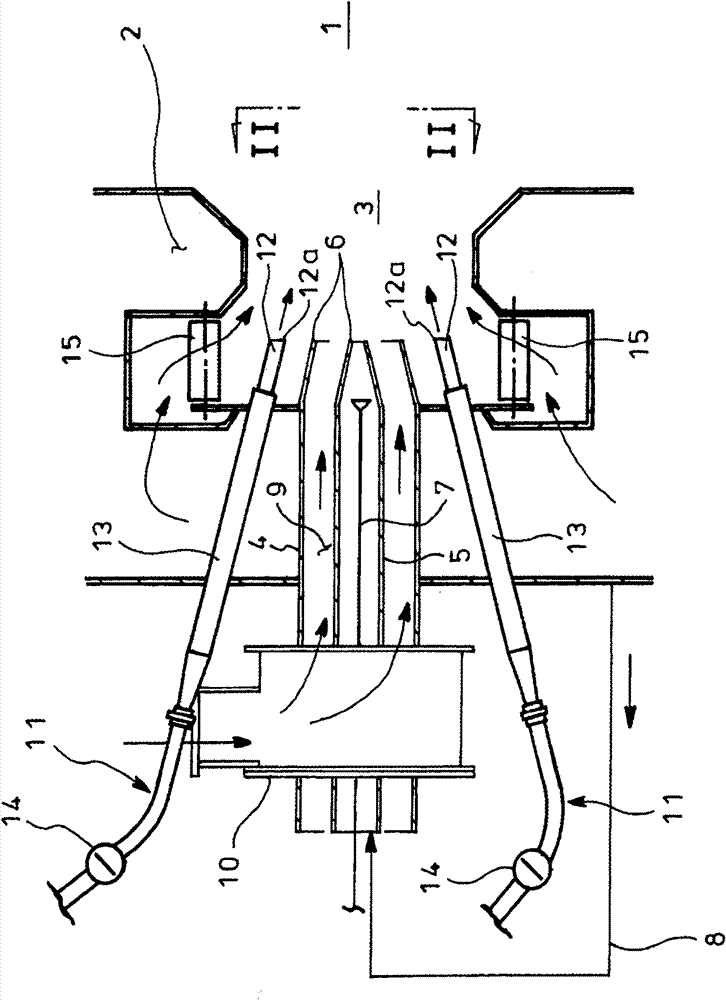

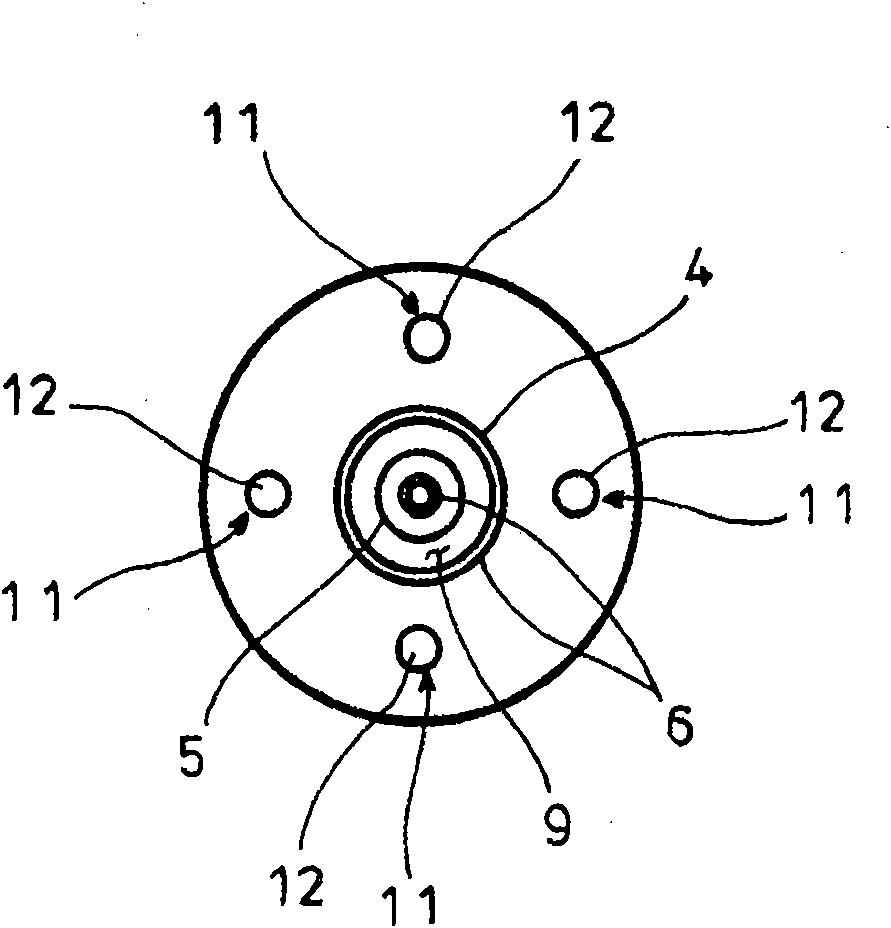

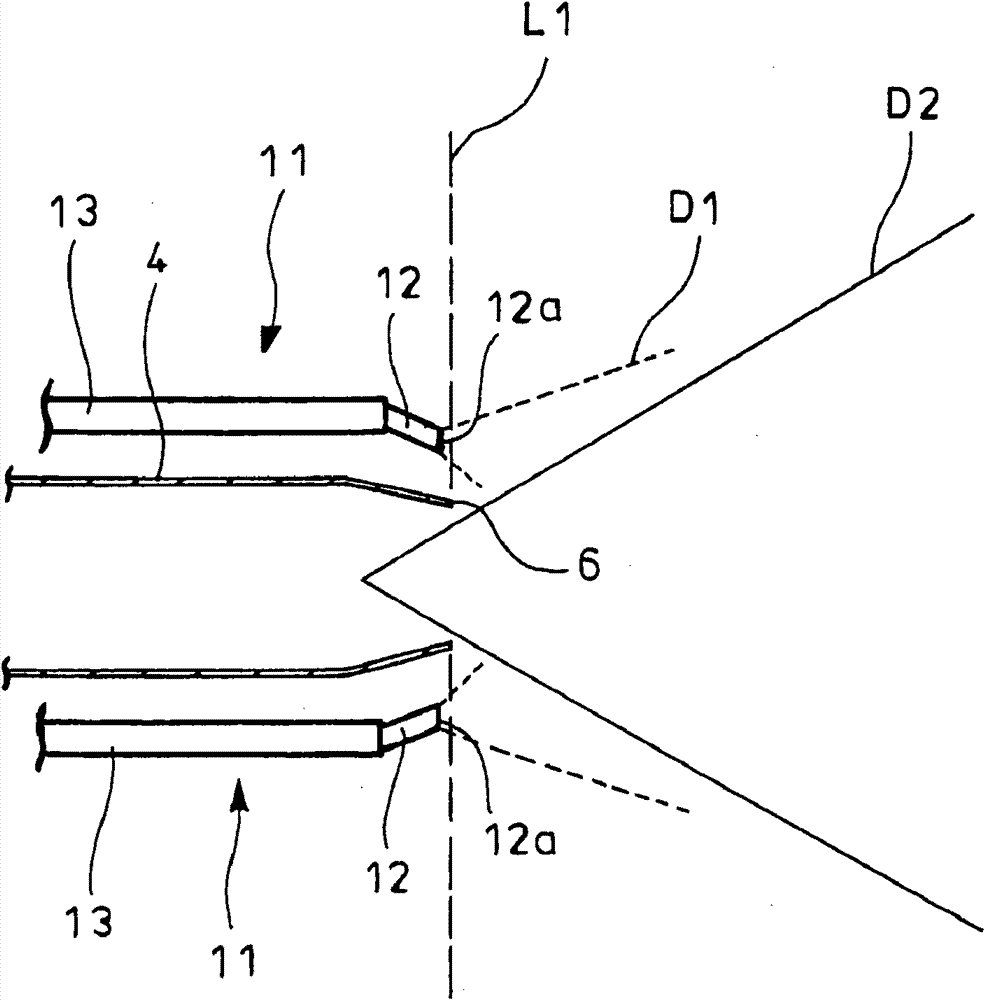

[0037] Figure 1 ~ Figure 3 It is an embodiment example of the pulverized coal burner of the oxygen combustion boiler of the present invention.

[0038] The pulverized coal burner of the oxygen combustion boiler in the embodiment example is provided with a burner outer cylinder 4 and a burner inner cylinder 5 in the same core shape. The air box 2 faces the throat 3 formed on the furnace wall (not shown) of the oxy-fuel boiler 1 , and the front end 6 of the burner outer cylinder 4 and the burner inner cylinder 5 opens toward the throat 3 .

[0039] There is a fuel burner 7 at the axial center of the burner inner cylinder 5 , and fuel such as oil is supplied to the fuel burner 7 from the outside of the burner inner cylinder 5 , and air from the wind box 2 is introduced into the burner inner cylinder 5 through the introduction line 8 .

[0040] Between the burner inner cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com