Bearings and Bearing Pads

A technology of bearings and gaskets, applied in the field of bearings and bearing gaskets, which can solve the problems of rising temperature of inclined gaskets, increased heat generation of lubricating oil, and inability to quickly absorb vibration of rotating shafts, etc., to achieve deformation suppression and temperature uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

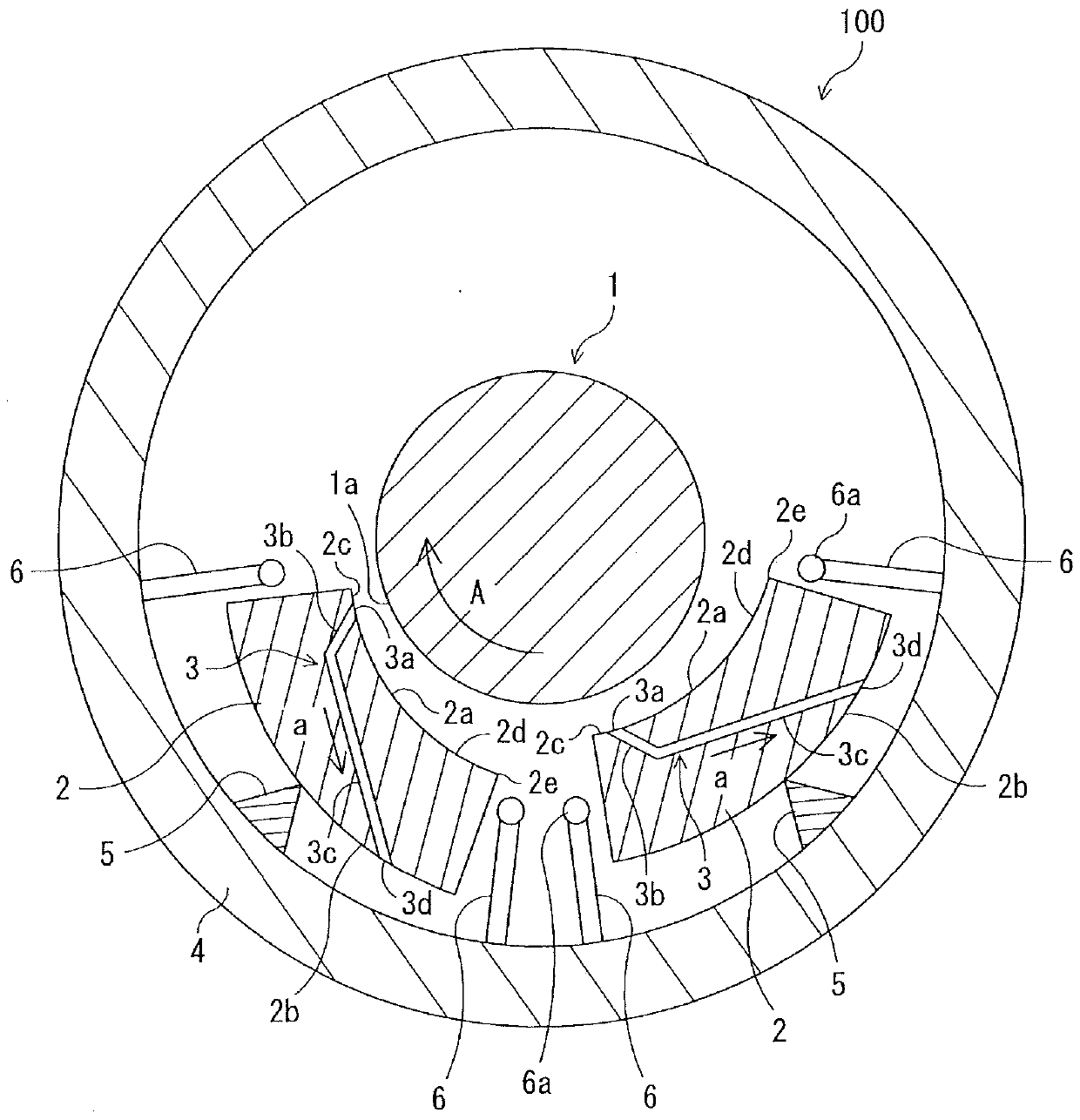

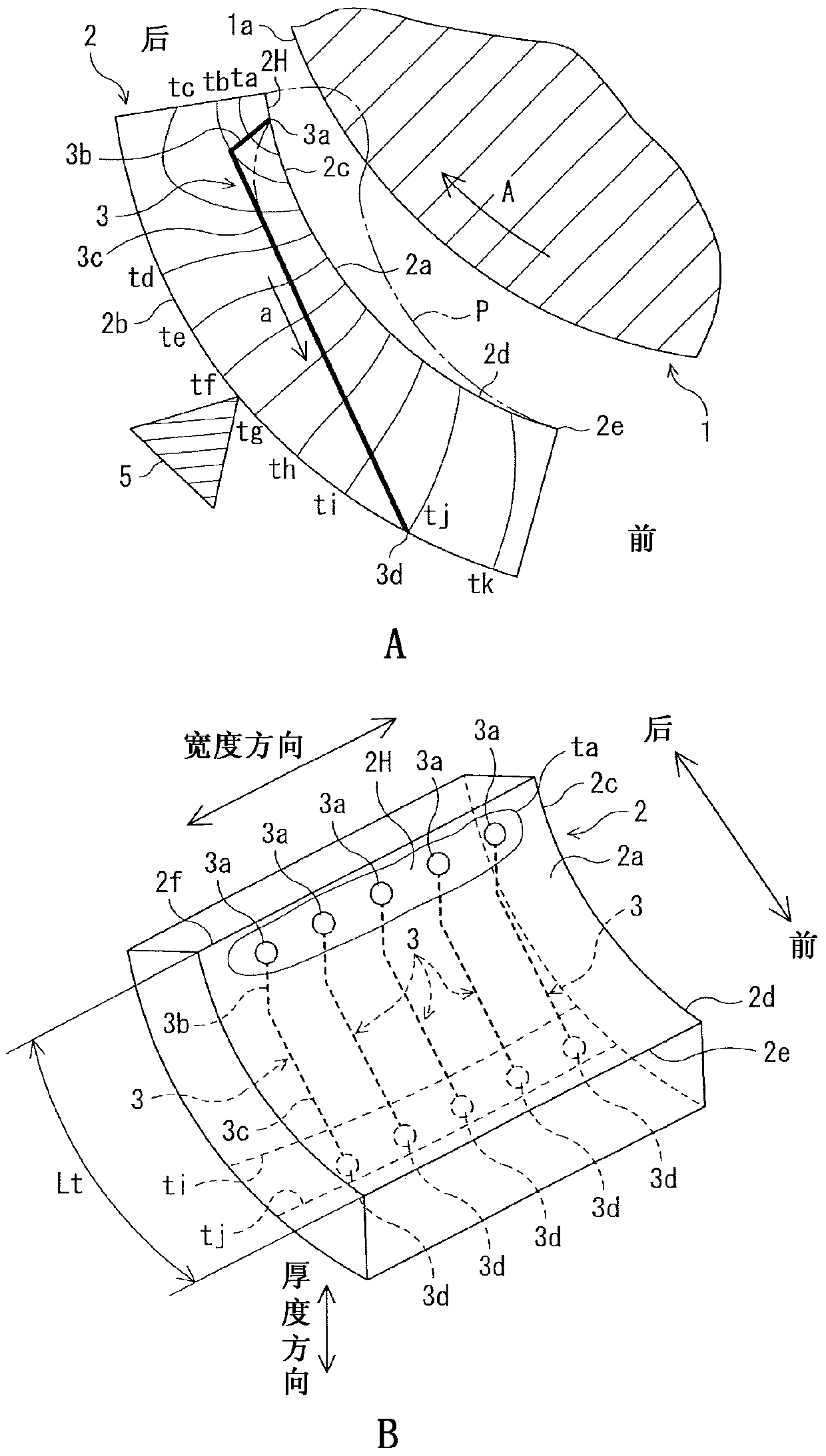

[0043] use Figure 1 ~ Figure 3 B describes the diagonal pad radial bearing and the bearing pad for the radial bearing as the first embodiment of the present invention.

[0044] [1-1. Overall structure of inclined pad radial bearing]

[0045] Such as figure 1 As shown, the bearing 100 as the first embodiment of the present invention constitutes the following radial bearing, which can rotate in the radial direction in the direction indicated by arrow A (hereinafter, also referred to as the rotation direction) in a rotatable manner Axis 1 is supported.

[0046] That is, the bearing 100 includes a plurality of (here, two) tilt pads (bearing pads according to the first embodiment of the present invention) 2 to support the rotating shaft 1 from vertically below; the bearing housing 4 is arranged in The circumference of the rotating shaft 1 and the inclined gasket 2; and the oil supply nozzle 6, which sprays lubricating oil from the spray portion 6a at the tip.

[0047] A plurality of (he...

no. 2 approach

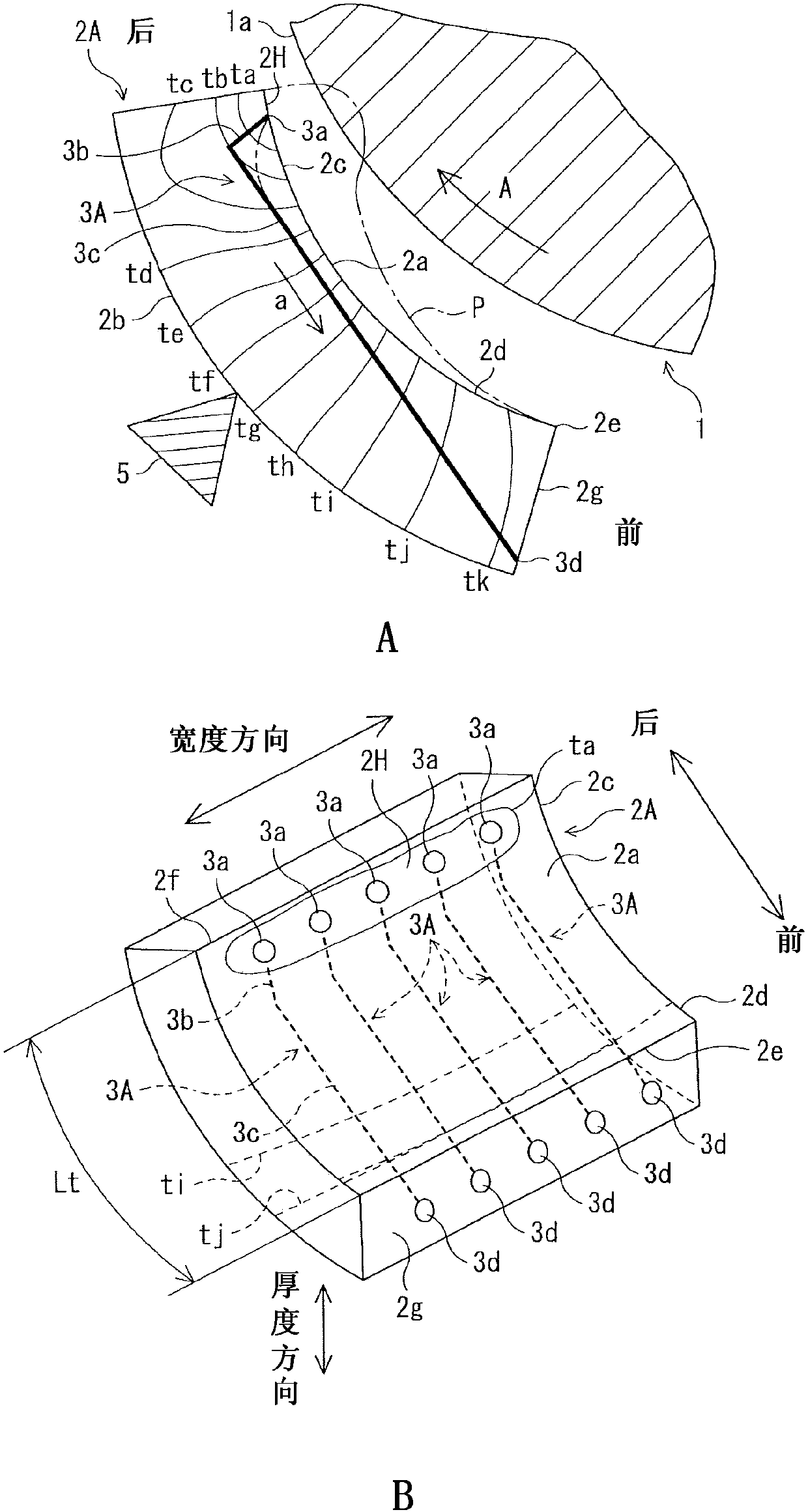

[0077] use image 3 A and image 3 B describes the bearing and the bearing pad as the second embodiment of the present invention. In addition, the same reference numerals are given to the same constituent elements as those of the first embodiment, and the description thereof is omitted.

[0078] [2-1. Tilt Pad Radial Bearing and Tilt Pad Structure for Radial Bearing]

[0079] As the bearing device of the second embodiment of the present invention, with respect to figure 1 The bearing 100 of the first embodiment shown is used instead of the tilt pad 2 image 3 A and image 3 The inclined pad shown in B (as the bearing pad of the second embodiment of the present invention) 2A.

[0080] In the inclined gasket 2 of the first embodiment, the outlet 3d through the flow path 3 is arranged on the back surface 2b of the gasket. In contrast, in the inclined gasket 2A of the present embodiment, the outlet 3d through the flow path 3A is arranged on the inclined The front surface of the pad 2A f...

no. 3 approach

[0087] use Figure 4 A. Figure 4 B. Figure 5 A and Figure 5 B describes the bearing and the bearing pad as the third embodiment of the present invention. In addition, the same reference numerals are given to the same constituent elements as in the above-mentioned respective embodiments, and the description thereof is omitted.

[0088] [3-1. Overall structure of tilt pad thrust bearing]

[0089] Such as Figure 4 A and Figure 4 As indicated by B, the bearing 200 as the third embodiment of the present invention is configured as a thrust bearing that supports the rotating shaft 21 rotating in the direction indicated by the arrow A (hereinafter, also referred to as the rotation direction) from the axial direction.

[0090] That is, the bearing 200 includes a tilt pad (bearing pad according to the third embodiment of the present invention) 22 for rotatably in the axial direction against a thrust ring integrated with the rotating shaft 21 in a flange shape (by The support portion) 21a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com