Glass substrate suction table, and method for processing of glass substrate

A technology for glass substrates and processing methods, applied in glass manufacturing equipment, glass cutting devices, metal processing equipment, etc., can solve the problems of glass substrate quality degradation, glass substrate becoming defective, glass substrate scratches, etc., to suppress scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the glass substrate adsorption table and the glass substrate processing method of the present invention will be described with reference to the drawings.

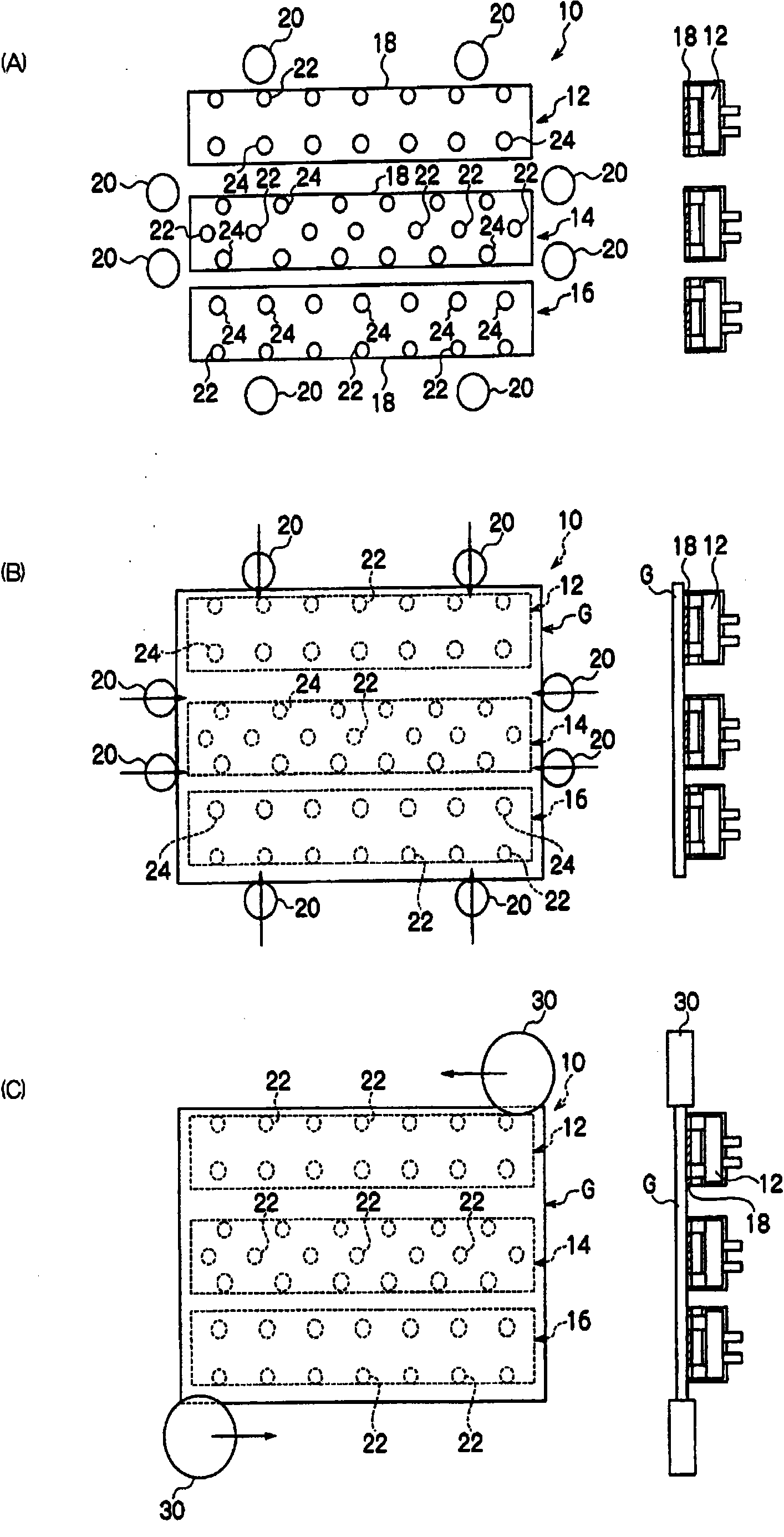

[0034] figure 1 (A) to (C) are explanatory diagrams showing the structure of the glass substrate suction table 10 of the glass substrate processing machine according to the embodiment, and the left figures of (A) to (C) respectively show a plan view of the glass substrate suction table 10, and the right The figures each show a side sectional view of the glass substrate adsorption table 10 . The glass substrate suction table 10 is a table set on a glass substrate edger, figure 1 Among them, three stages 12 , 14 , and 16 divided into elongated rectangular shapes are configured as a planar rectangular shape corresponding to the shape of the glass substrate G as a whole. In addition, the number of divisions of the glass substrate adsorption stage 10 is not limited to three, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com