Thermal protect pcram structure and methods for making

A technology of memory and memory components, applied in static memory, digital memory information, information storage, etc., can solve the problems of resistive switching performance attenuation, composition change, memory cell failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] refer to Figures 1 to 11 Embodiments of the present invention will be described in detail.

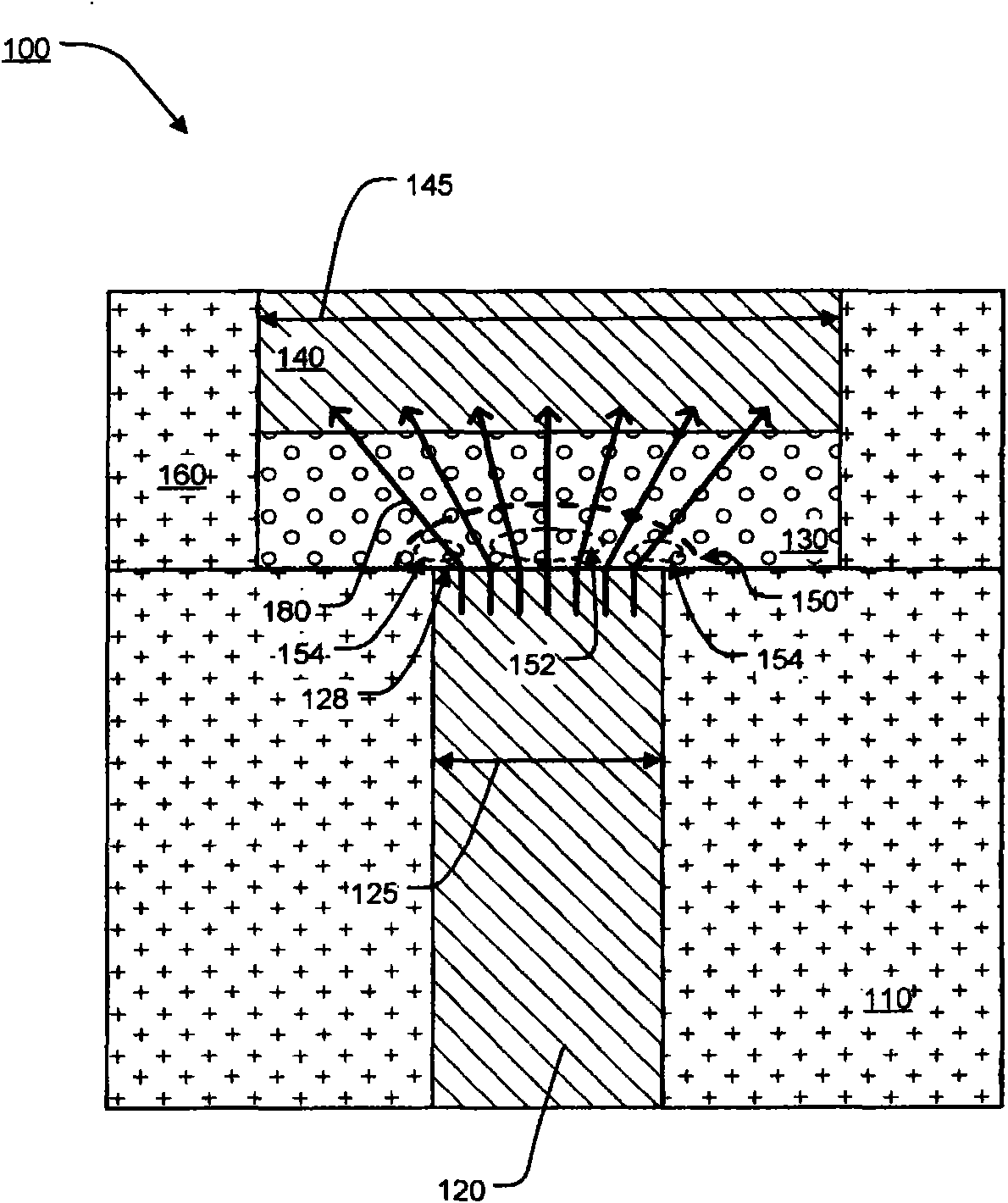

[0030] figure 1 Shown is a cross-sectional view of a known art "mushroom-type" memory cell 100 having a bottom electrode 120 extending through a dielectric layer 110; a phase-change memory element 130 including a bottom electrode 120 a phase change material layer on the top; and the top electrode 140 on the phase change memory element 130 . A dielectric layer 160 surrounds the phase change memory element 130 . as available from figure 1 It can be seen that the width 125 of the bottom electrode 120 is smaller than the width 145 of the top electrode 140 and the phase change memory element 130 .

[0031] In operation, the voltage on the top and bottom electrodes 140, 120 induces a current to flow from the top electrode 140, through the phase change memory element 130, to the bottom electrode 120, or in the opposite direction.

[0032] Active region 150 refers to the region of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com