Multifunctional biological solid fermentation tank

A biosolids and fermenter technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-processing, etc., can solve the problem of uneven temperature, difficult inoculation, uneven mixing, etc. It can solve the problem of single function, reduce production cost and equipment investment, uniform inoculation and control humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

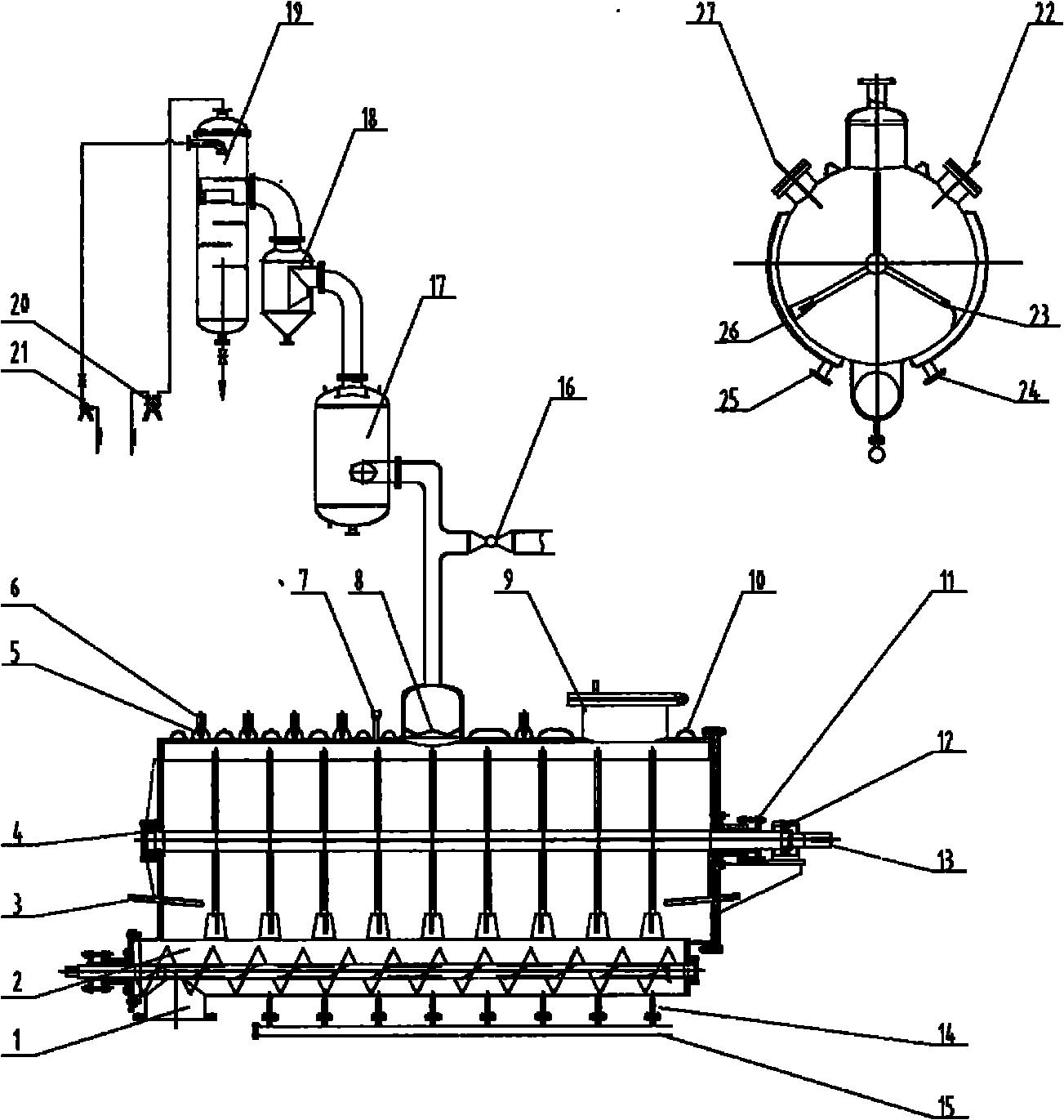

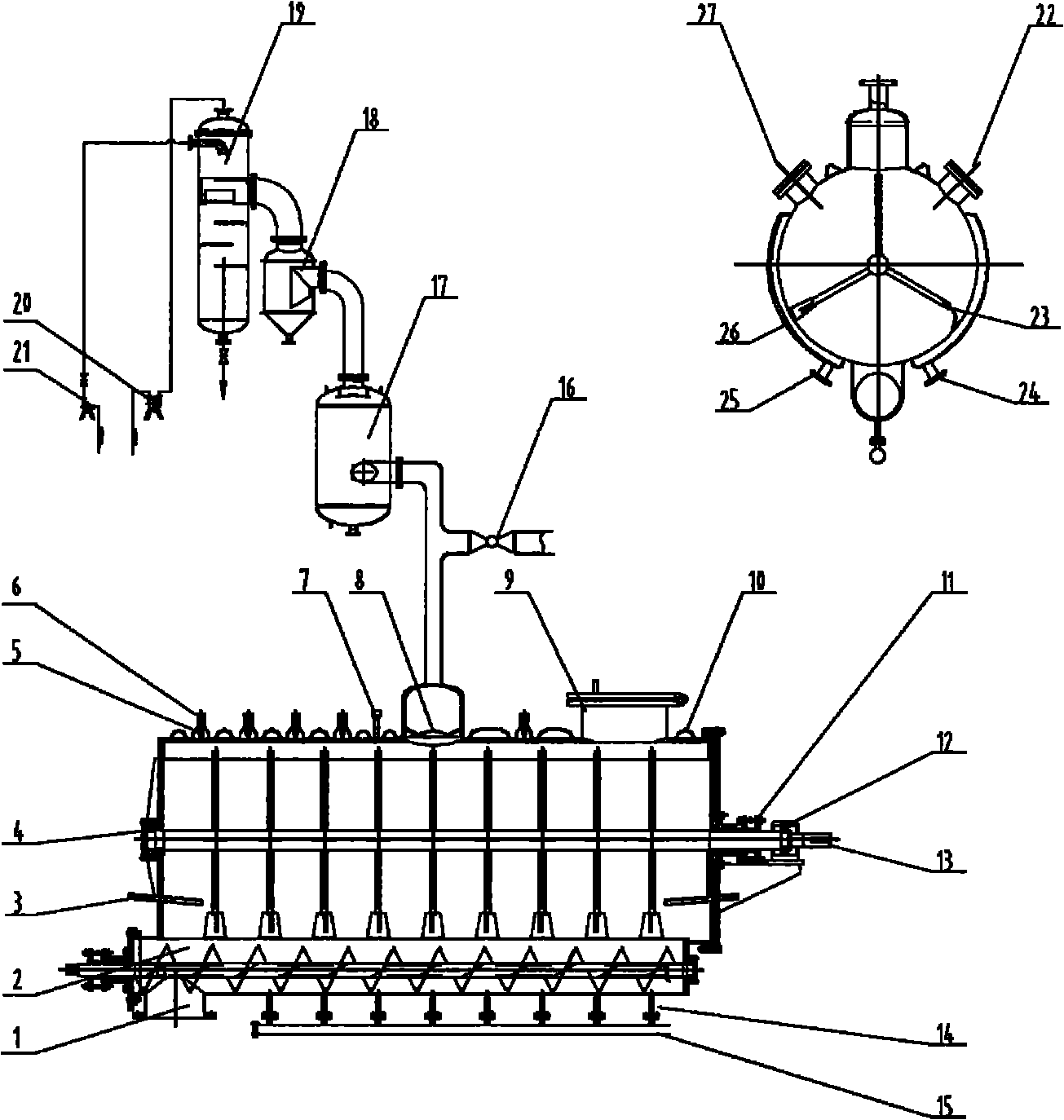

[0011] The features of the present invention can be illustrated by the following structural diagrams and examples.

[0012] figure 1 Indicated that in this example ( figure 1 ) Sectional view of a multifunctional biosolids fermenter.

[0013] The steps of the embodiment are as follows: the fermentation raw material is fed into the solid fermentation tank through mechanical or manual feeding from the feed port 9, the feeding amount is about 50% of the total volume of the tank, and appropriate water is added; the speed-regulating main motor and the auger motor at the bottom of the tank are started , the horizontal propeller blade 23 and the auger 2 move in the opposite direction to stir the material in the tank to make the material uniform; the feeding port 9 is closed, and the steam main pipe 15 and the steam distribution pipe 14 of the lower part of the auger under the bottom of the tank are passed into 120 Steam at -125°C sterilizes the material at high temperature; the jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com