Pyrolysis and gasification cracking furnace for solid biomass

A technology of solid biomass, pyrolysis and gasification, applied in the gasification of granular/powder fuel, manufacture of combustible gas, petroleum industry, etc. low gasification efficiency, etc., to achieve the effects of purification and disposal, high gas quality, and high gasification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

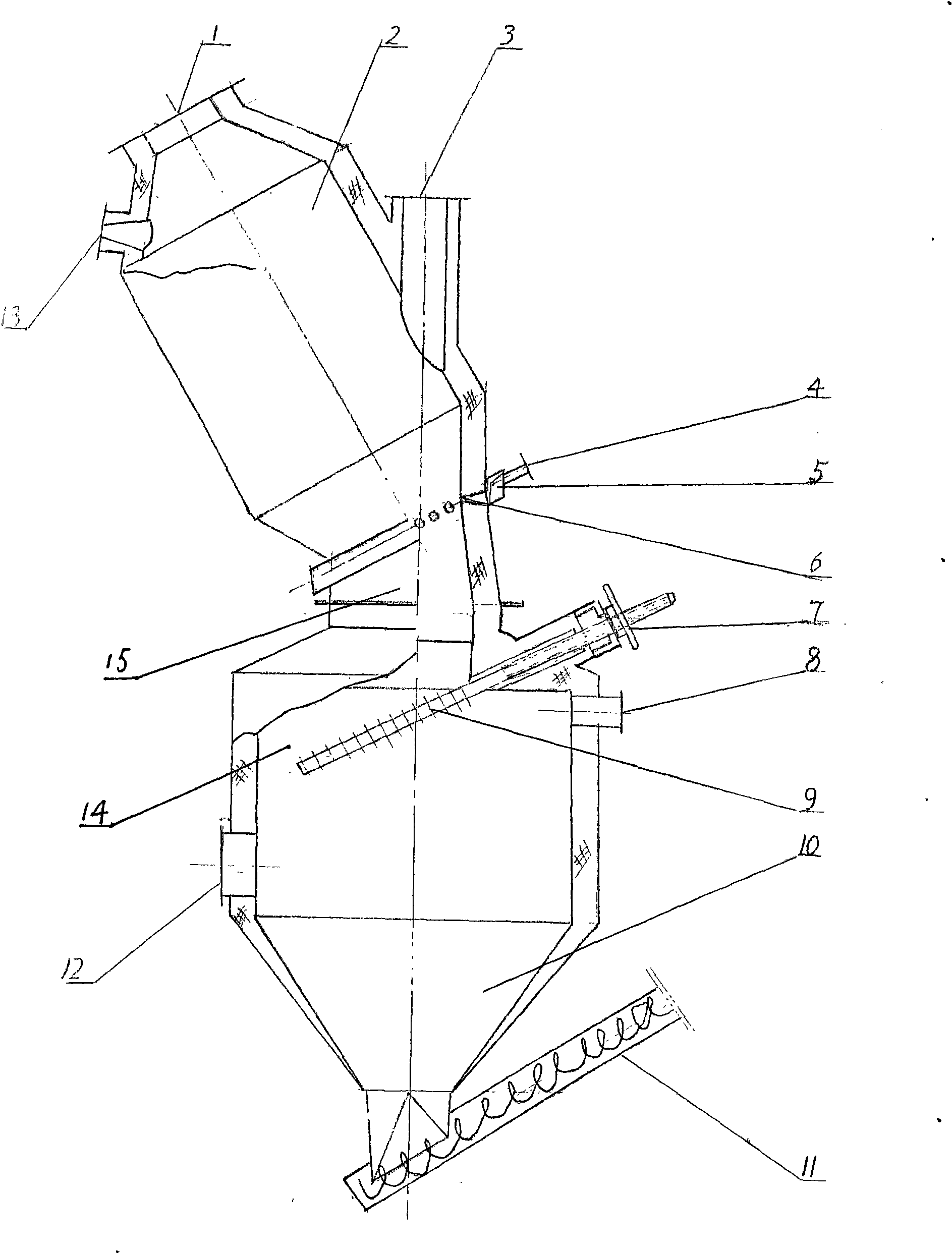

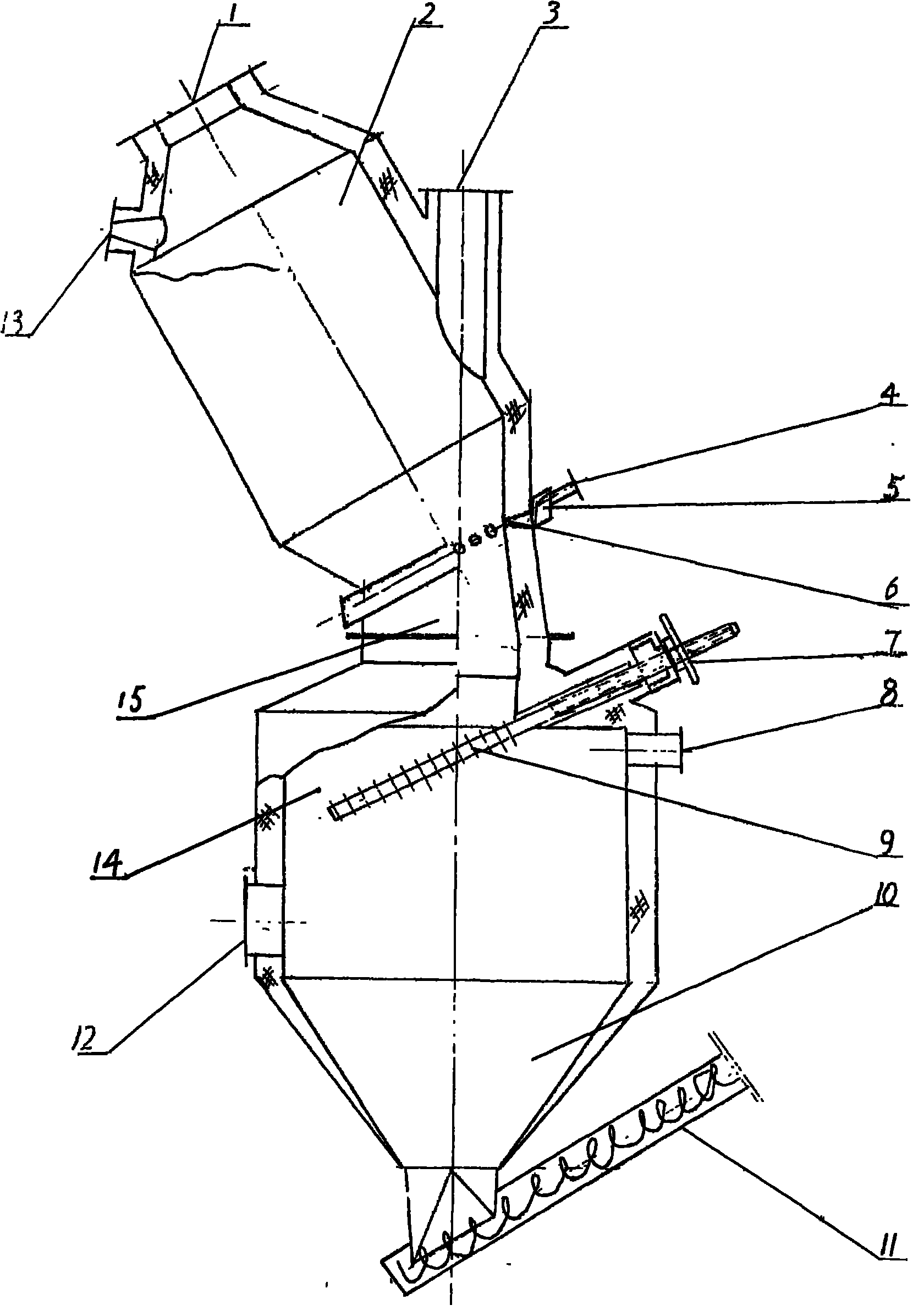

[0025] Example: Combine figure 1 , the solid biomass pyrolysis gasification cracking furnace of the present embodiment comprises the upper boiling gasification furnace 2 and the lower gas primary purification chamber 14, the boiling gasification furnace 2 is obliquely arranged above the gas primary purification chamber 14, and the gas primary The upper part of the purification room is provided with a plug-in grate 9 that can adjust the insertion depth. The plug-in grate 9 is adjusted to the depth inserted into the gas primary purification chamber 14 through the plug-in grate adjustment mechanism 7. At the bottom of the boiling gasifier, there is a The gasification agent inlet 4 and the gasification agent nozzle 6 are provided with a gas outlet 8 below the plate grate 9, and the upper part of the fluidized gasifier is provided with a material inlet 3 and an ignition hole 13, and the ignition hole 13 doubles as an observation hole.

[0026] In the specific setting, the lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com