Drilling platform of pipe numerical control drilling machine

A CNC drilling and drilling technology, which is applied to the components of boring machines/drilling machines, drilling/drilling equipment, boring/drilling and other directions, can solve the problems of poor safety, low processing efficiency and poor processing quality, and achieve convenient The effect of safe processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

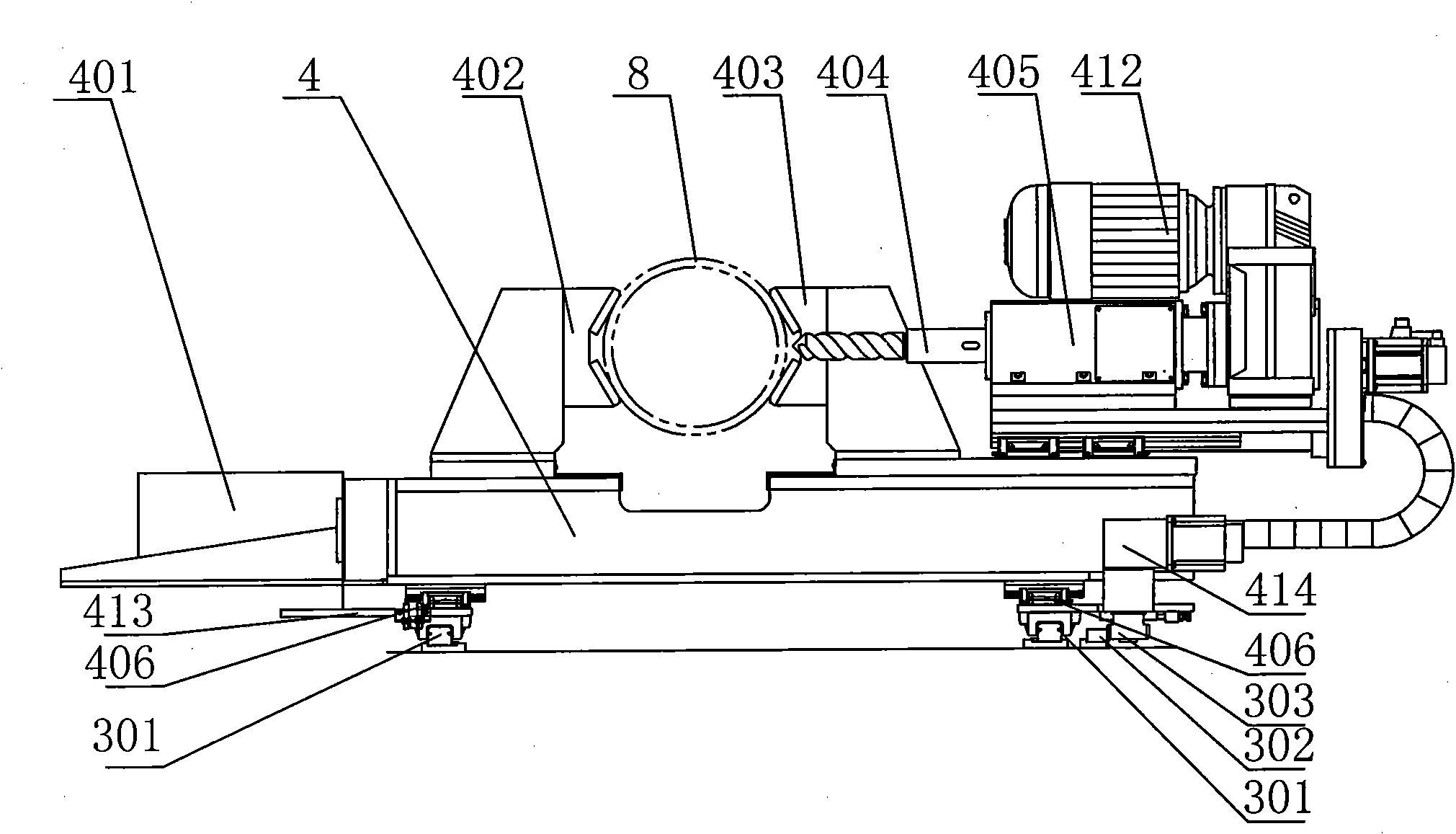

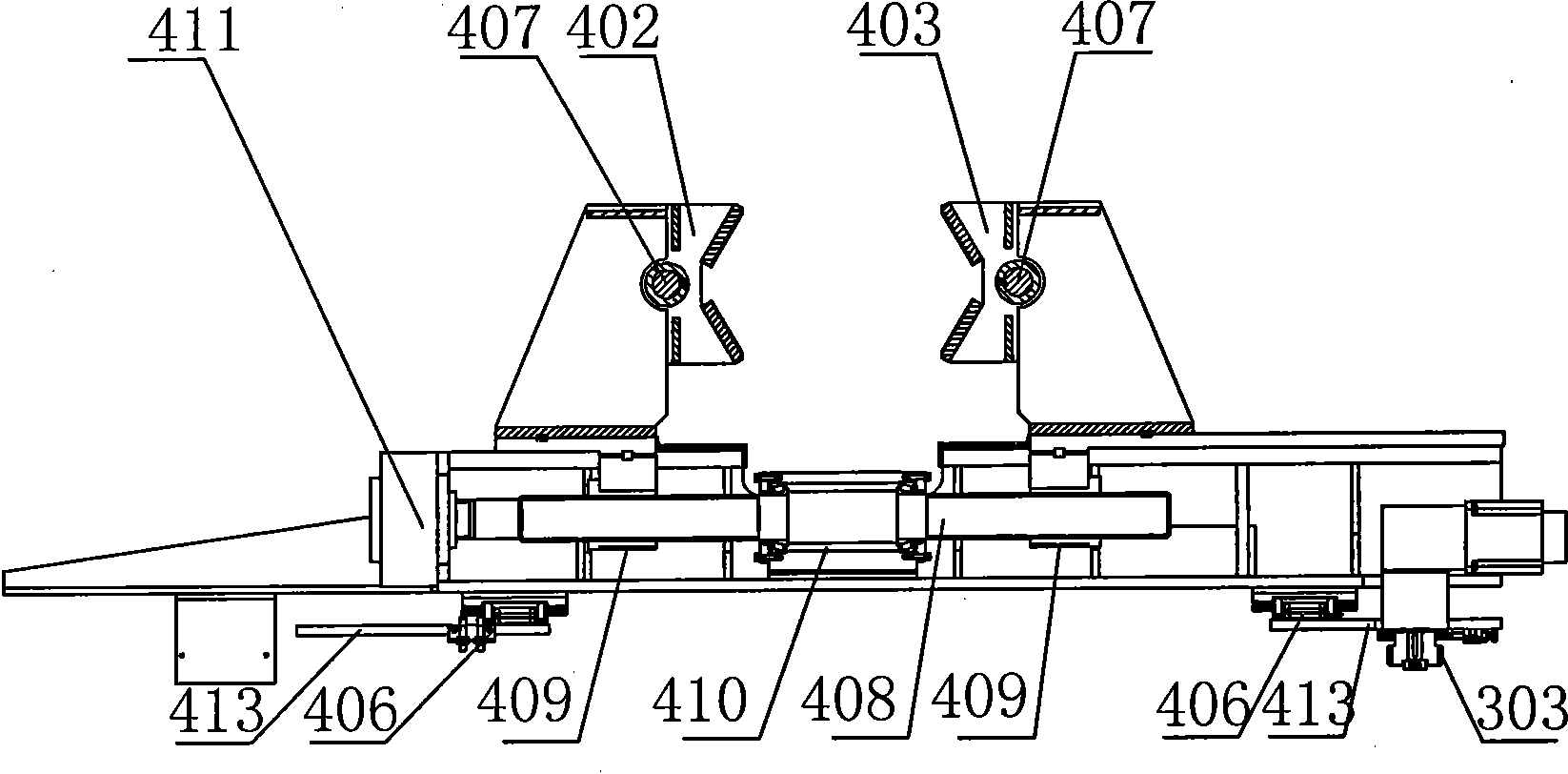

[0014] Such as figure 1 , figure 2 As shown, the CNC drilling machine is composed of bed 1, pipe spindle rotation device 2, transmission guide device 3, mobile drilling platform 4, clamping tailstock 5, chip removal device 6, hydraulic device, lubrication device, etc., and is controlled by CNC Platform 7 performs centralized electrical and hydraulic control. Both ends of the pipe 8 are clamped by the active rotary chuck 201 of the main shaft rotary device 2 and the passive rotary chuck 501 that can move and clamp the tailstock 5, and rotate around the central axis driven by the active rotary chuck 201, And the passive rotary chuck 501 of clamping tailstock 5 passively follows rotation.

[0015] See figure 1 , figure 2 The mobile drilling platform 4 described in the present invention is arranged between the main shaft turning device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com