Manufacturing method of bucket tooth and applied mould thereof

A bucket tooth and mold technology, which is applied in the field of bucket tooth manufacturing, can solve problems such as difficulty in fully exerting material properties, low dimensional accuracy of tooth cavity and pin hole, and slow cooling speed of sand molds, so as to achieve fine grain size, high strength, and solidification fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

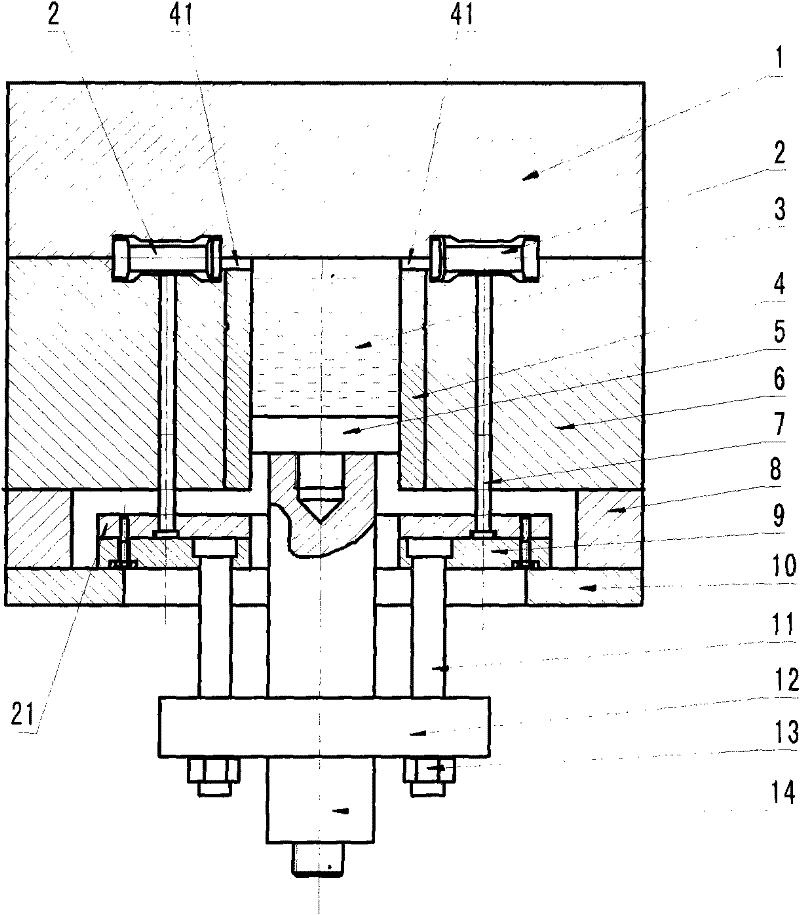

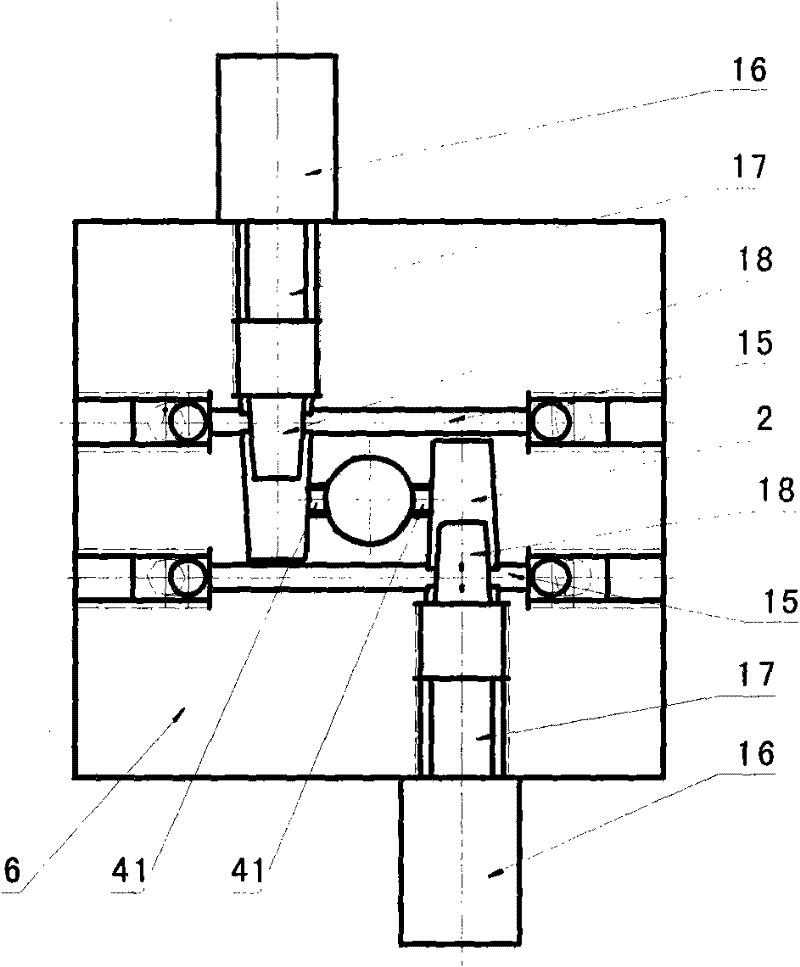

[0071] The preparation method of PC100 bucket tooth comprises the following steps:

[0072] Step 1: Pour smelted ZGMn13 melt at a temperature of 1400°C into the material storage cavity 4 at a pouring height lower than the opening 41 on the upper part of the material storage cavity; the volume of the melt in the material storage cavity is 1.30 times the volume of the bucket tooth cavity.

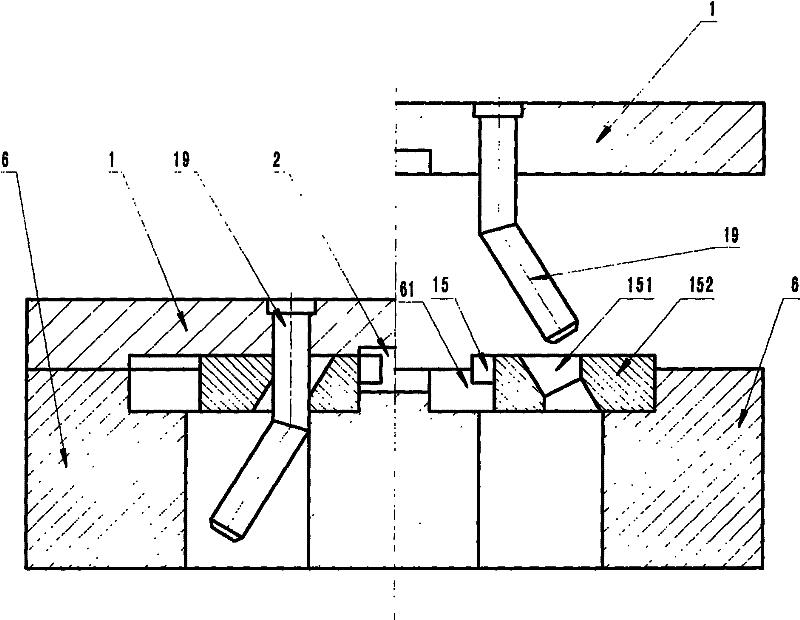

[0073] Step 2. While the upper mold 1 is moving downward, use the straight-slant pin core-pulling mechanism to push the pin hole core 15 and the tooth cavity core 18 into the cavity 2 of the bucket tooth mold to the limit, while keeping the pressure constant, The upper and lower molds are closed to hold pressure, and the holding pressure is 3000KN.

[0074] Step 3: start the lower cylinder of the hydraulic press, drive the pressure head 5 to push the liquid bucket tooth material 3 in the material storage chamber 4, make it pass through the gap 41 at the upper end of the material storage chamb...

Embodiment 2

[0081] Preparation of wear-resistant alloy steel 22SiMn2NiMo PC200 bucket teeth

[0082] The method for preparing wear-resistant alloy steel 22SiMn2NiMo bucket tooth PC200 of the present invention uses a hydraulic press that is a three-beam four-column vertical hydraulic press, including two independent hydraulic systems of an upper cylinder and a lower cylinder. The upper cylinder is fixed on the upper beam of the hydraulic press, and the lower end of the piston rod is fixed on the movable beam of the hydraulic press. The nominal pressure is 10,000KN, and the no-load speed is 300mm / s. It can track the solidification shrinkage for continuous pressure maintenance, and is used to apply top-down pressure. . The lower cylinder is fixed on the lower beam, and the upper end of the piston rod is firmly connected to the pressure head 5 through the lower cylinder piston connecting rod. The nominal force of the lower cylinder is 3000KN, which can track the function of solidification shr...

Embodiment 3

[0092] Preparation of wear-resistant alloy steel 75MnCr2MoNi bucket tooth PC1000

[0093] The method for preparing wear-resistant alloy steel 75MnCr2MoNi bucket teeth PC1000 in the present invention uses a hydraulic press with three beams and four columns, including two independent hydraulic systems of an upper cylinder and a lower cylinder. The upper cylinder is fixed on the upper beam of the hydraulic press, and the lower end of the piston rod is fixed on the movable beam of the hydraulic press. The nominal pressure is 15000KN, and the no-load speed is 200mm / s. It can track the solidification shrinkage for continuous pressure maintenance, and is used to apply top-down pressure. . The lower cylinder is fixed on the lower beam, and its piston rod is firmly connected with the pressure head 5 through the piston connecting rod of the lower cylinder. The nominal force of the lower cylinder is 5000KN, which can track the function of solidification shrinkage and continuous pressuriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com