Plastic bag cultivation method of oyster mushrooms

A bag-type cultivation and oyster mushroom technology, which is applied in botanical equipment and methods, fertilizer mixtures, horticulture and other directions, can solve problems such as not yet mature cultivation technology and restrict the development of oyster mushroom cultivation industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

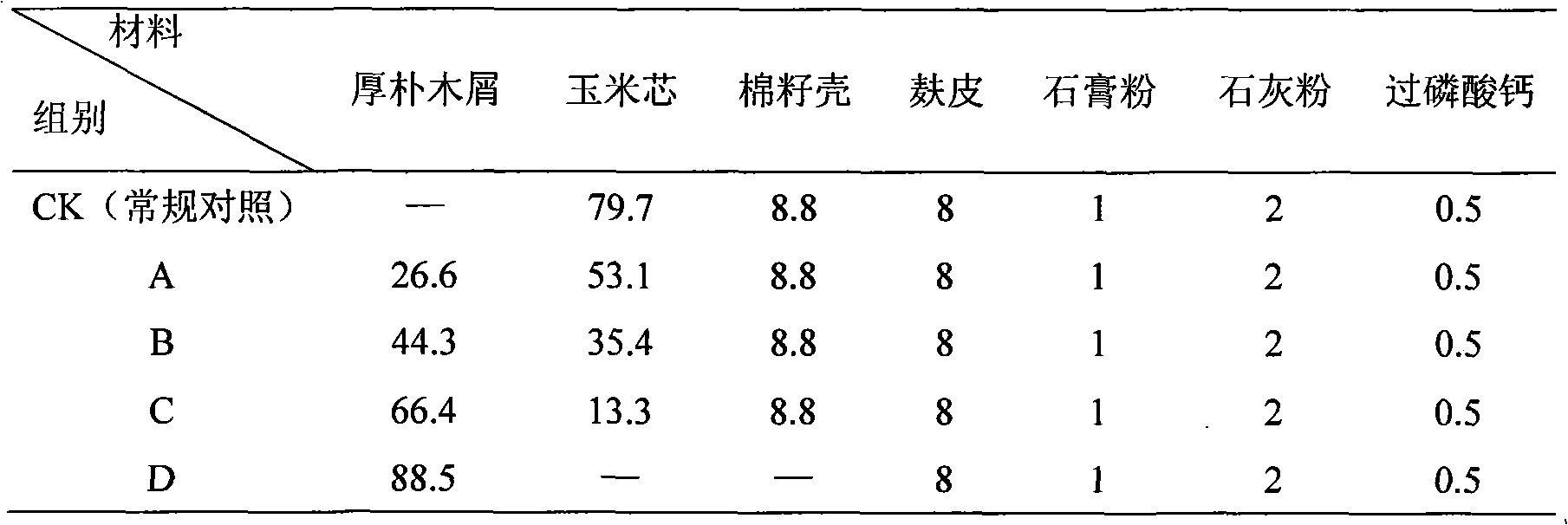

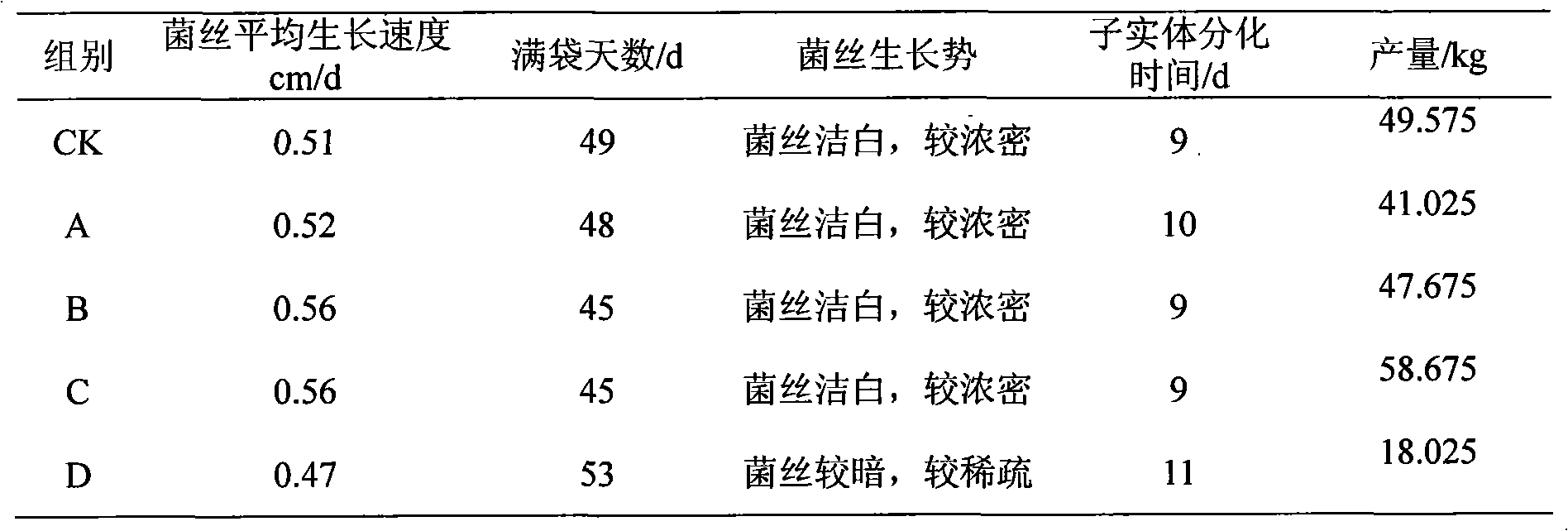

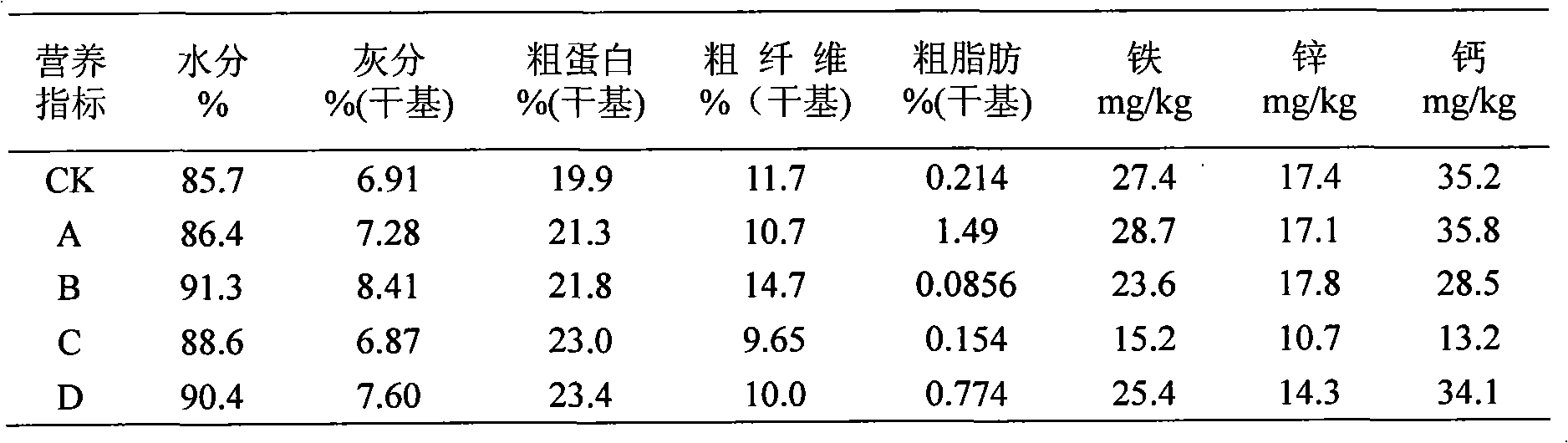

Embodiment 1

[0012] Crush magnolia officinalis branches dried in the sun after removing the bark into (1~1.5cm)×(1~1.5cm)×(0.1~0.15cm) size wood chips, press 100 bags (use length, width and thickness 43cm×22cm× 0.3mm polyethylene bag), calculated as 2 catties of dry material per bag, weighed 132 catties of Magnolia officinalis wood chips (66%), soaked in water for 7 to 10 days, to make it fully absorb water, until the water-soaked wood chips particles can be seen water but lightly pinched by hand Just enough to not flow. Add corn cob 13.5%, cotton seed hulls 9%, bran 8%, gypsum powder 1%, lime powder 2%, superphosphate 0.5%, mixing materials, bagging, sterilization (after 4 hours at normal pressure and high temperature, reach 100°C, Sterilize for 24 hours, cease fire, and stuffy overnight). Select Pleurotus ostreatus heterozygous strains for open inoculation in the sterilized inoculation room or in the inoculation box. After inoculation, transfer the bacteria bag to the mushroom room, and c...

Embodiment 2

[0014] Crush magnolia officinalis branches dried in the sun after removing the bark into (1~1.5cm)×(1~1.5cm)×(0.1~0.15cm) size wood chips, press 100 bags (use length, width and thickness 43cm×22cm× 0.3mm polyethylene bag), calculated as 2 catties of dry material per bag, weighed 88 catties of Magnolia officinalis wood chips (44%), soaked in water for 7 to 10 days, to make it fully absorb water, until the water-soaked wood chips particles can be seen water but lightly pinched by hand Just enough to not flow. Add 35.5% corncob, 9% cottonseed hull, 8% bran, 1% gypsum powder, 2% lime powder, 0.5% superphosphate, mix, bag, sterilize (after 4 hours at normal pressure and high temperature, reach 100°C, Sterilize for 24 hours, cease fire, and stuffy overnight). Select Pleurotus ostreatus heterozygous strains for open inoculation in the sterilized inoculation room or inoculation box. After inoculation, transfer the bacteria bag to the mushroom room, and germinate at a temperature of 5°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com