Fuel tank for motor vehicles made of thermoplastic plastic

A technology for fuel tanks and fuel tanks, which is applied to vehicle components, the arrangement combined with the fuel supply of internal combustion engines, and the lower structure, which can solve the problems of reducing the compressive strength of plastic tanks and achieve the effect of reducing the pressure per unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

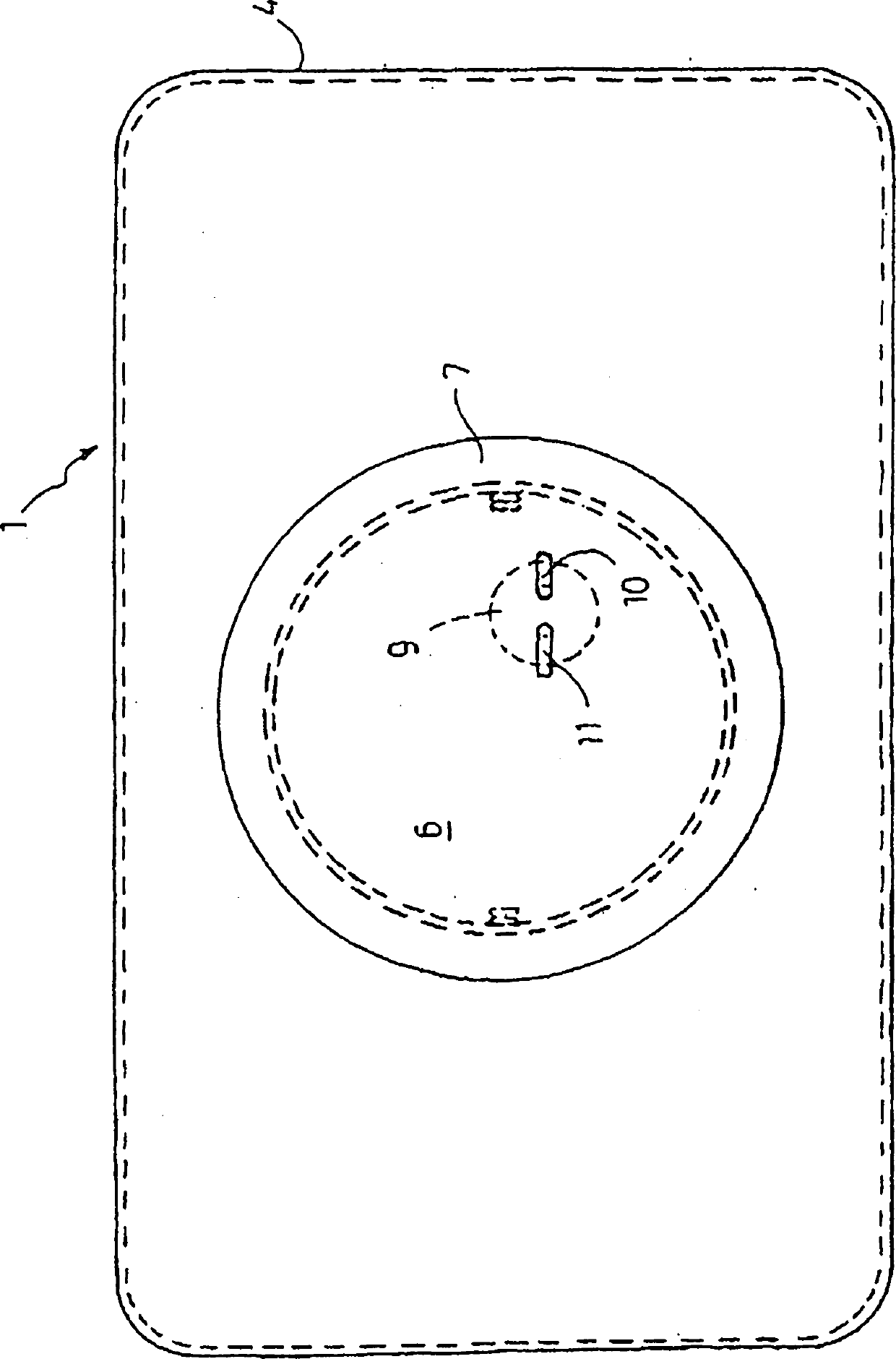

[0030] exist figure 1 shows a fuel tank 1 according to the invention. The fuel tank 1 is formed in a known manner as a fuel tank made of thermoplastic. The tank can be produced, for example, in one piece by extrusion blow molding. figure 1 A greatly simplified sectional view of a fuel tank 1 according to the invention is shown. For reasons of simplification, the filling pipes of the fuel tank 1 and the means for filling and venting are not shown.

[0031]The tank wall 4 of the fuel tank 1 is provided with an opening 6 above the installation location and an opening 5 below the installation location. The two openings 5 , 6 are arranged aligned with one another in mutually opposing sections of the tank wall and have substantially the same diameter. Furthermore, the openings 5 , 6 are also provided as circular openings in the tank wall 4 . A delivery unit 2 extending over the entire height of the fuel tank is inserted into the openings 5 , 6 and accommodates a fuel pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com