Construction method of building pile foundation

A construction method and technology of construction piles, which are applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems of building safety performance, pile foundation compressive strength, large porosity, etc., and improve waterproof and anti-seepage performance , Improve the compressive strength and impermeability, improve the effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

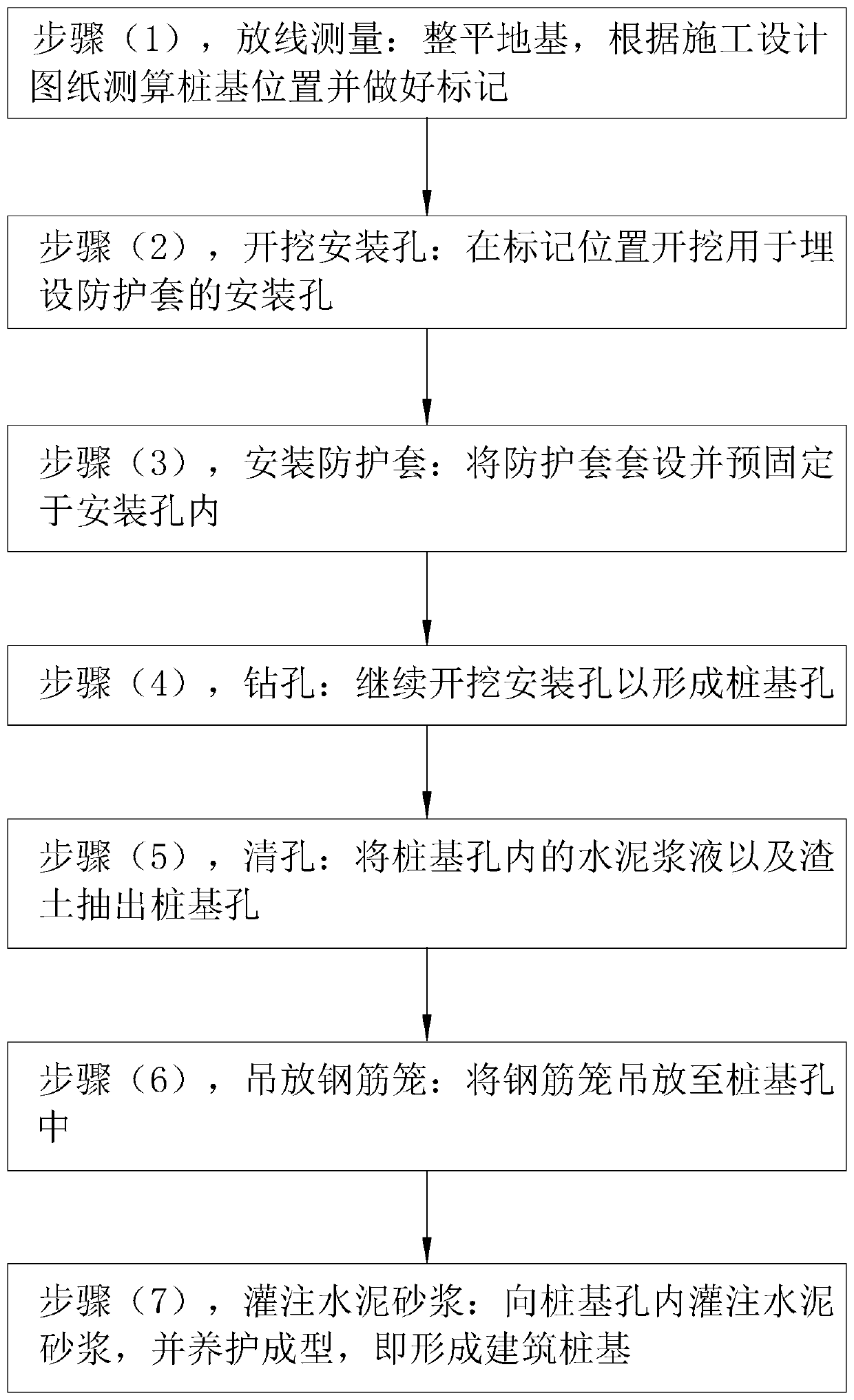

[0076] refer to figure 1 , is a kind of construction method of building pile foundation disclosed by the present invention, comprises the following steps:

[0077] Step (1), measuring and setting out, is as follows:

[0078] Level and tamp the foundation, then measure and mark the position of the pile foundation according to the construction design drawings.

[0079] Step (2), excavate the installation hole, as follows:

[0080] According to the size of the protective cover, excavate the installation hole for burying the protective cover at the position marked in step (1), and make the excavation depth of the installation hole consistent with the length of the protective cover.

[0081] Step (3), install the protective cover, as follows:

[0082] The protective sleeve is set on the opening of the mounting hole, and the protective sleeve is pressed against the inner wall of the mounting hole, so that the protective sleeve is pre-fixed in the mounting hole.

[0083] Step (4)...

Embodiment 2

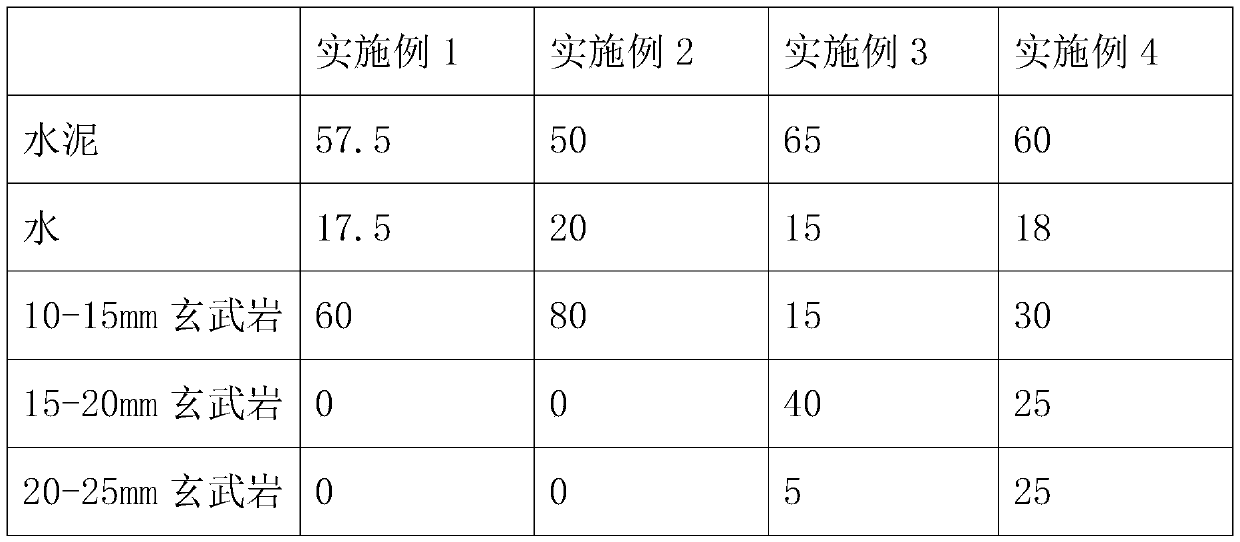

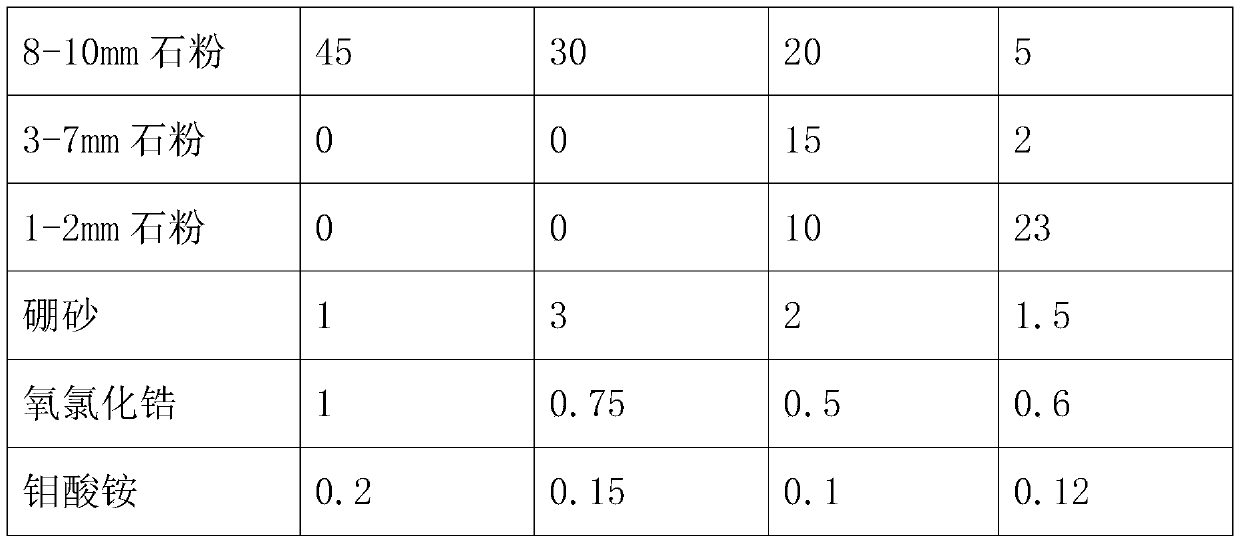

[0093] The difference from Example 1 is that the raw material components and contents of the cement mortar are shown in Table 1.

Embodiment 3

[0095] The difference from Example 1 is that the raw material components and contents of the cement mortar are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com