Layer stranded optical cable, preparation method thereof and device for method

A layer-twisted, optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of cost increase, water infiltration, damage to optical cable performance, etc., and achieve the effect of simple structure, good combination, and avoiding longitudinal water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

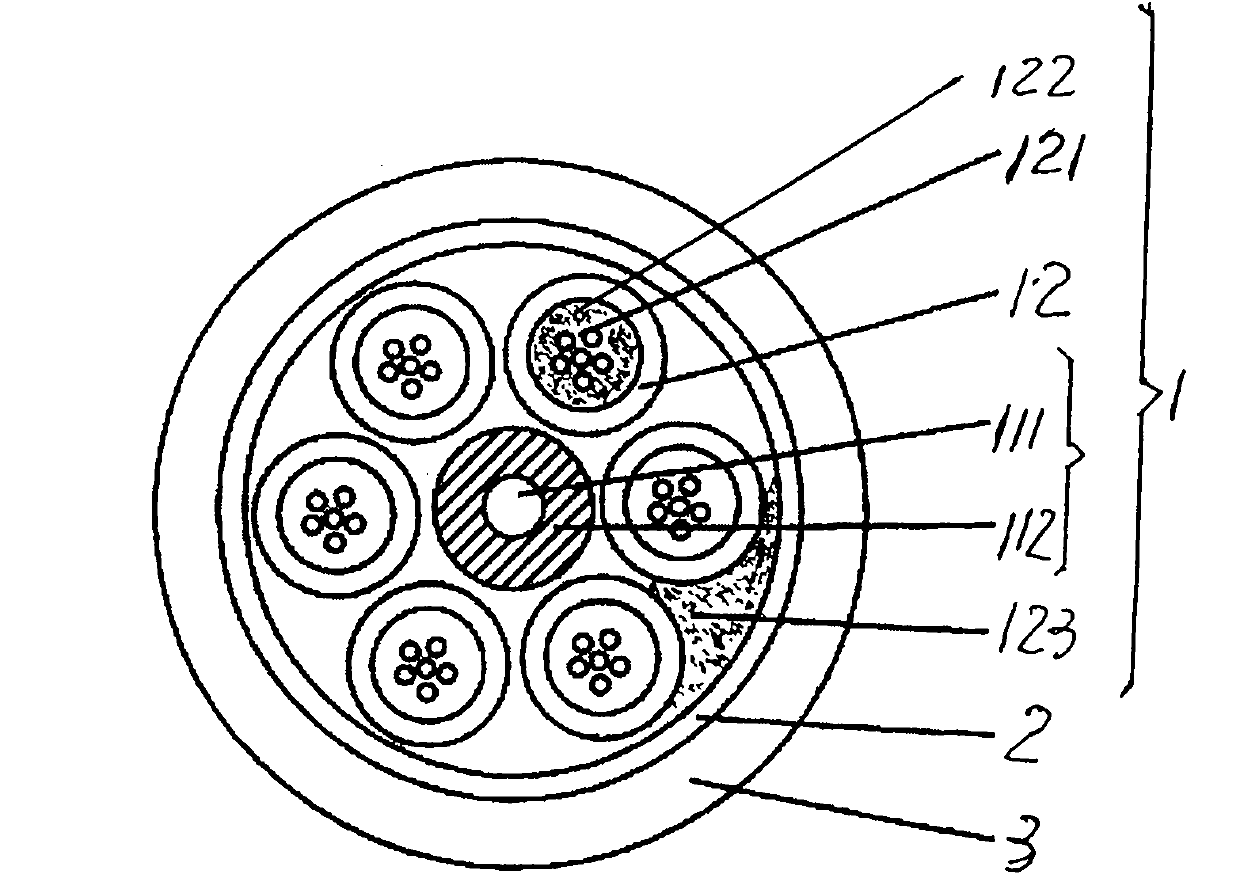

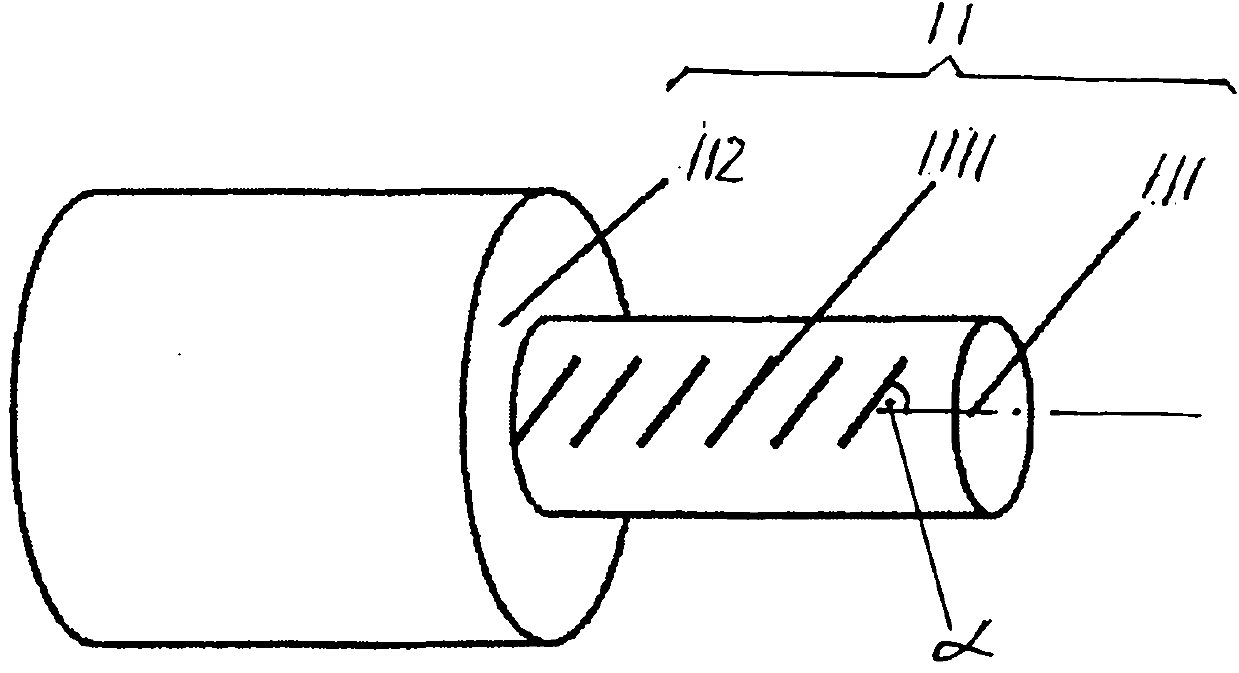

[0049] This example is for the preparation of figure 1 In terms of the layer twisted optical cable of the structure shown.

[0050] please see figure 1 , Figure 4 and Figure 6 , prepared by figure 1 The method for the layer twisted optical cable of the shown structure comprises the following steps:

[0051] A) Optical fiber coloring that will be used to accommodate the figure 1 As shown, the optical fibers 121 in the five loose tubes 12 that constitute the cable core 1 are introduced into the optical fiber coloring machine for coloring, and the outer surfaces of the optical fibers 121 are combined with identifiable colors to obtain colored optical fibers. Because in this embodiment, each There are six optical fibers 121 in each loose tube 12, and the cross-sectional shape of each optical fiber 121 is circular, therefore, six optical fibers 121 are colored into six different colors by an optical fiber coloring machine, and different colors can provide identification (ide...

Embodiment 2

[0062] This example is for the preparation of figure 2 In terms of the layer twisted optical cable of the structure shown.

[0063] please see figure 2 , Figure 5 and Figure 7 , prepared by figure 2 The method for the layer twisted optical cable of the shown structure comprises the following steps:

[0064] A) Optical fiber coloring that will be used to accommodate the figure 2 As shown, the optical fibers 121 in the six loose tubes 12 that constitute the cable core 1 are introduced into the optical fiber coloring machine for coloring, and the outer surfaces of the optical fibers 121 are combined with identifiable colors to obtain colored optical fibers. Because in this embodiment, each There are six optical fibers 121 in each loose tube 12, and the cross-sectional shape of each optical fiber 121 is circular, therefore, six optical fibers 121 are colored into six different colors by an optical fiber coloring machine, and different colors can provide identification (...

Embodiment 3

[0071] sketches. Only change the quantity of the loose tube 12 described in step A) into three, and change the root number of the optical fiber 121 in each loose tube 12 into ten; change the diameter of the steel wire 111 in step C) into 2.1 mm, the depth of the groove 1111 is changed to 0.21 mm; the protective layer 2 in step E) is changed to a polyester film tape; the material of the sheath layer 3 in step F) is changed to low-smoke halogen-free flame-retardant polyethylene. All the other are the same as the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com