Method for measuring coal bunker material level based on laser and binocular vision and device thereof

A material level measurement and binocular vision technology, which can be used in measurement devices, lubrication indicating devices, liquid/fluid solid measurement, etc., and can solve problems such as poor initiative, complex structure of the display part, and poor working reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Preferred embodiments of the present invention will be described in detail below with reference to the examples shown in the accompanying drawings, wherein like reference numerals are used to designate like parts.

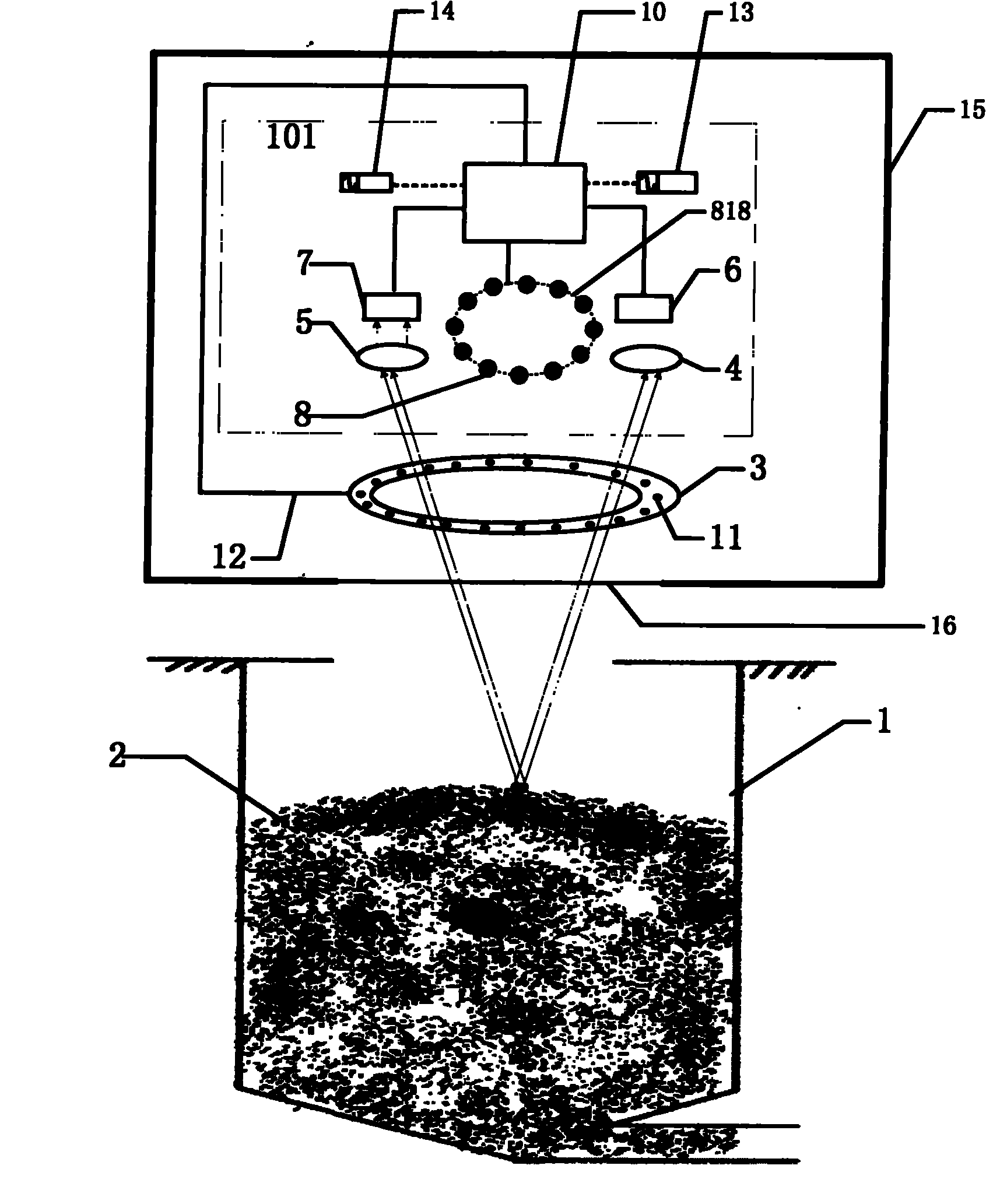

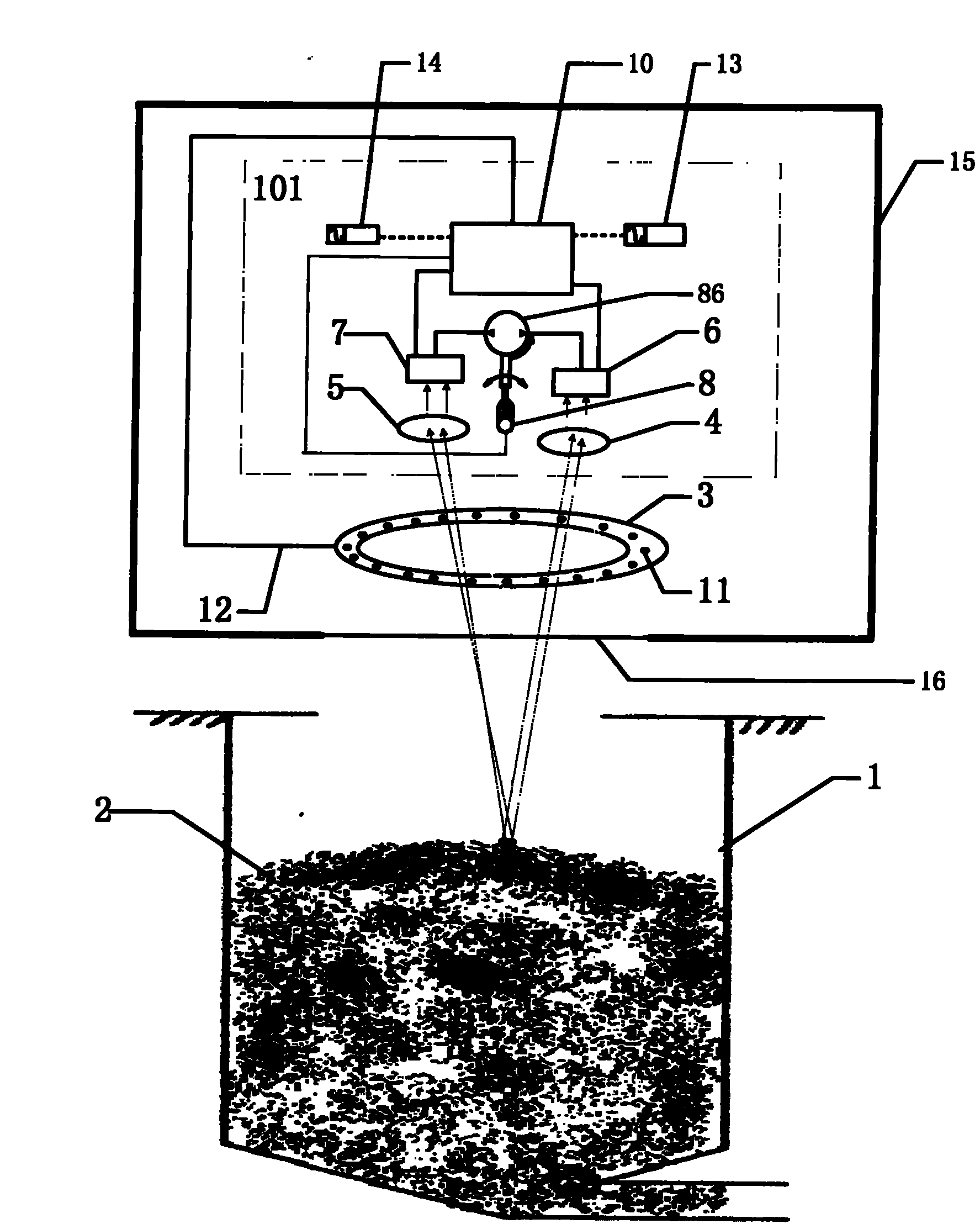

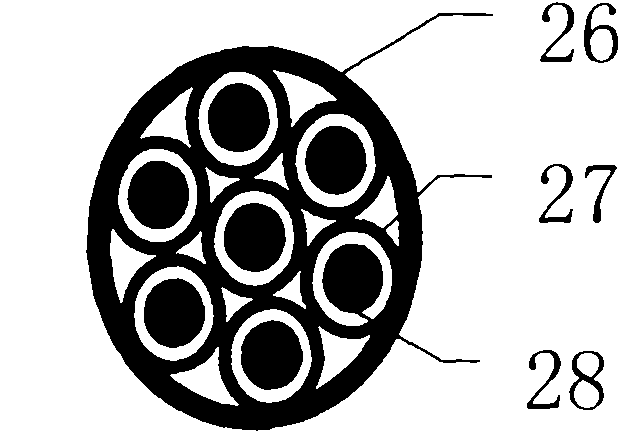

[0075] figure 1 It is a schematic plan view of the laser and binocular vision coal bunker material level measuring device when multiple lasers are used in the present invention. Such as figure 1 As shown, the coal bunker level measuring device of the present invention includes a plurality of lasers 8, two CCD cameras with the same parameters: camera 6 and camera 7, two parameters: lens 4 and lens 5, light source 3. Flameproof enclosure 15 and enclosure window 16. When the device works in the optional sensor mode, the device also includes a coal loading sensor 14 and a coal unloading sensor 13 . The above-mentioned laser 8 generates a laser beam, and the size of the laser beam is adjusted according to the depth of the coal bunker material level. Describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com