Biomass grate firing boiler

A biomass layer and boiler technology, which is applied to combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of limiting the development distance of biomass boilers, complicated processes, and large investment, reducing heat loss and improving Thermal efficiency, ensure full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

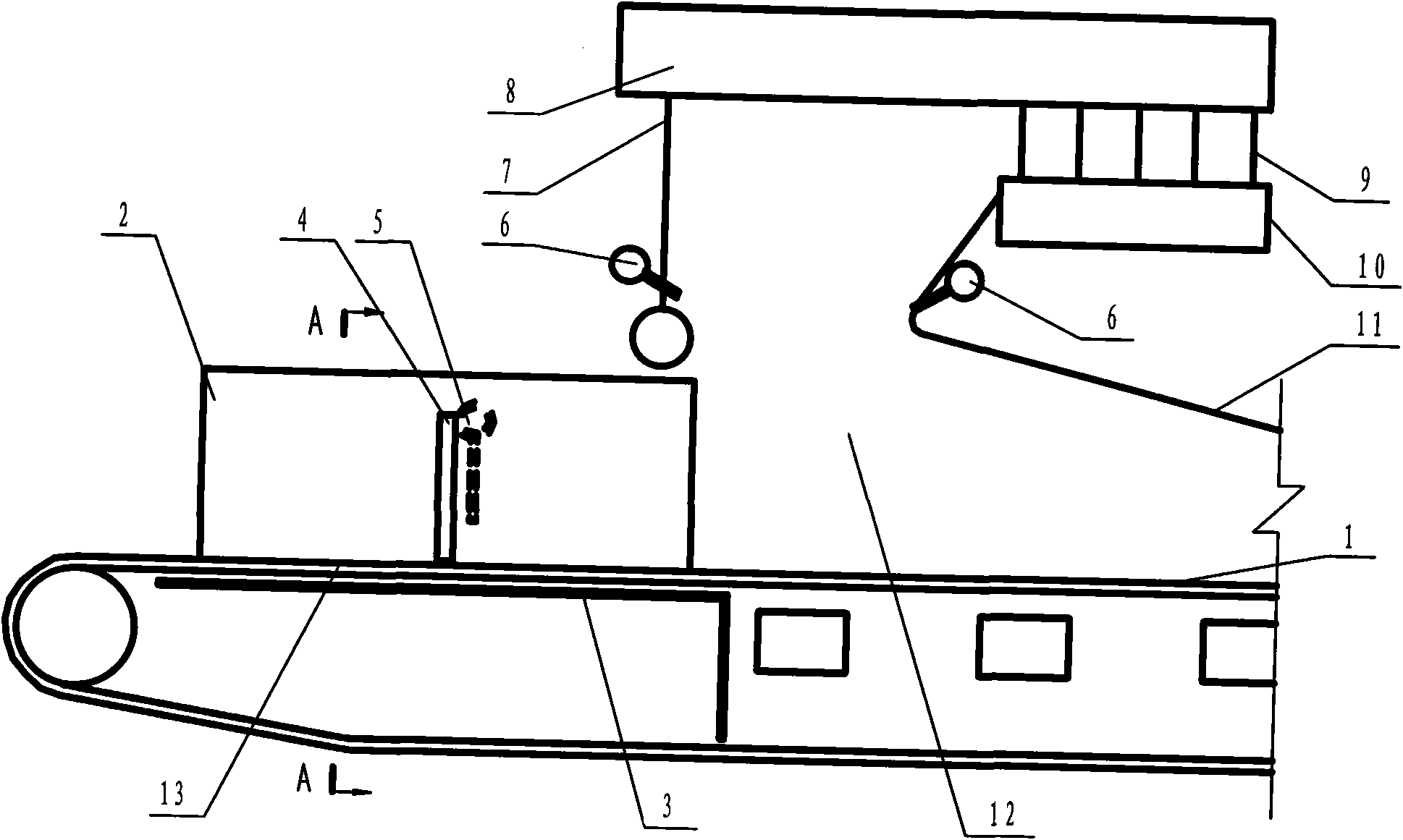

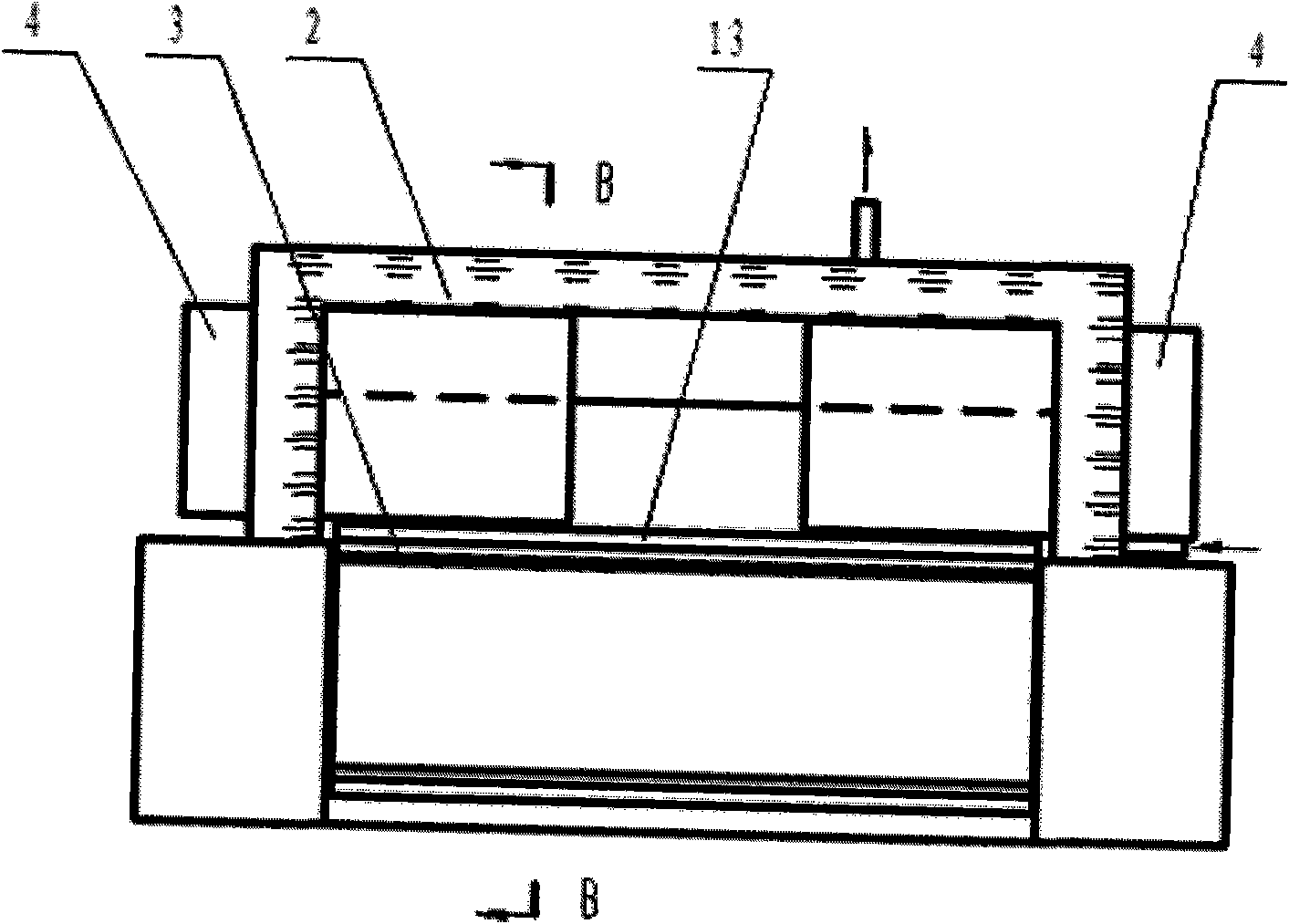

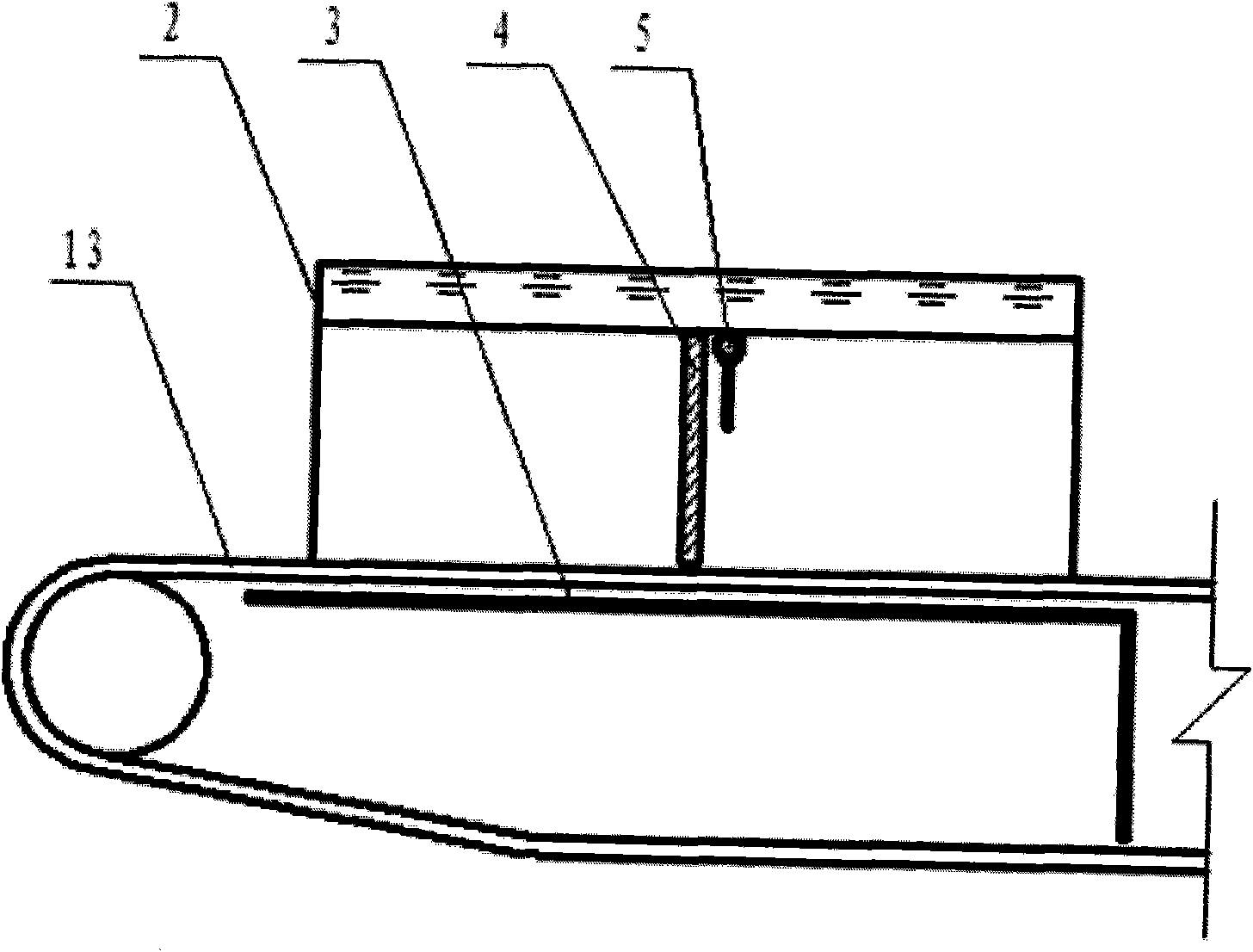

[0015] figure 1 It is a schematic diagram of the structure and principle of the biomass layer-fired boiler involved in the present invention. The present invention is composed of moving grate 1, water cooling jacket 2, furnace 12, rear arch 11, membrane wall 7, upper drum 8, lower drum 10, convection tube bundle 9 and the like.

[0016] Different from ordinary grate furnaces, the front end of the furnace of the present invention is not provided with a front arch, and the front wall of the furnace 12 adopts a membrane-type wall 7 structure to form a front-wall membrane-type wall, which not only simplifies the furnace structure, but also front-wall membrane-type wall 7 It is closely combined with the left and right water walls to form a closed furnace, which ensures the sealing, reduces air leakage and heat dissipation loss, improves the thermal efficiency of the boiler, and better adapts to the combustion of biomass fuel.

[0017] The front end of the moving grate 1 of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com