Method for preparing angiotensin converting enzyme inhibitory peptide (ACEIP) by using enzymatic degradation on mussel-digested protein

A blood pressure-lowering peptide and mussel technology, applied in the field of bioengineering, can solve the problems of low activity of the blood pressure-lowering peptide ACE inhibitory peptide, etc., and achieve the effects of strong industrial implementation, ACE inhibition and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1. A method for preparing antihypertensive peptides by enzymatically hydrolyzing mussel protein, followed by the following steps:

[0044] 1). Prepare defatted dried mussel powder:

[0045] After the fresh blue mussels are cleaned with water, the shells are removed and the shreds are removed. After being homogenized by a beater to a paste, the fresh blue mussels are freeze-dried (-50°C, 72 hours) to obtain mussel powder. Add the mussel powder to a 95% volume concentration ethanol solution at a ratio of 1g:4ml at 40℃ to defat for 4 hours, repeat three times; vacuum dry the mussel powder after the above degreasing treatment at 40℃ (5 hours), crush And pass a 100-mesh sieve to obtain defatted dried mussel powder with a moisture content of ≤2.34%.

[0046] 2) Weigh 5.0g of the above-mentioned defatted dried mussel powder (protein weight content 60.23%) into the enzyme reactor, add 100ml deionized water and stir evenly, homogenize for 10min, adjust the pH to 9.2 with 0.5mo...

Embodiment 2

[0058] Example 2. A method for preparing antihypertensive peptides by enzymatically hydrolyzing mussel protein, followed by the following steps:

[0059] 1). Prepare defatted dried mussel powder:

[0060] Replace fresh purple mussel with fresh thick-shell mussel, and the rest are the same as in Example 1.

[0061] 2) Weigh 5.0g of defatted dried mussel powder (protein weight content 72.56%) in the enzyme reactor, add 100ml deionized water and stir evenly, homogenize for 10min, adjust the pH to 9.2 with 0.5mol / L NaOH solution; Get the mixture.

[0062] 3). Raise the temperature of the mixture to 60℃ and stir to preheat, and keep it under stirring for 20 minutes; then add 0.075g of alkaline protease (Alcalase, enzyme activity of 9.4×10 4 U / g) Start the enzymatic hydrolysis reaction, the enzymatic hydrolysis temperature is 60-65°C, continuous stirring, keep the temperature and pH of the reaction system constant, and the enzymatic hydrolysis time is 240 minutes. Get the product of enzyma...

Embodiment 3

[0073] Example 3. A method for preparing antihypertensive peptides by enzymatically hydrolyzing mussel protein, followed by the following steps:

[0074] 1). Prepare defatted dried mussel powder:

[0075] The same as in Example 1.

[0076] 2) Weigh 200.0g of defatted dried mussel powder (protein weight content 60.23%) in the enzyme reactor, add 5L deionized water and stir evenly, homogenize for 10min, adjust the pH to 9.3 with 0.5mol / L NaOH solution; Get the mixture.

[0077] 3). Raise the temperature of the mixed solution to 65℃ and stir to preheat, and keep it under stirring for 20 minutes; then add 2.0g of alkaline protease (Alcalase, enzyme activity of 9.4×10 4 U / g) Start the enzymatic hydrolysis reaction, the enzymatic hydrolysis temperature is 65°C, continuous stirring, keep the temperature and pH of the reaction system constant, and the enzymatic hydrolysis time is 180 minutes. Get the product of enzymatic hydrolysis.

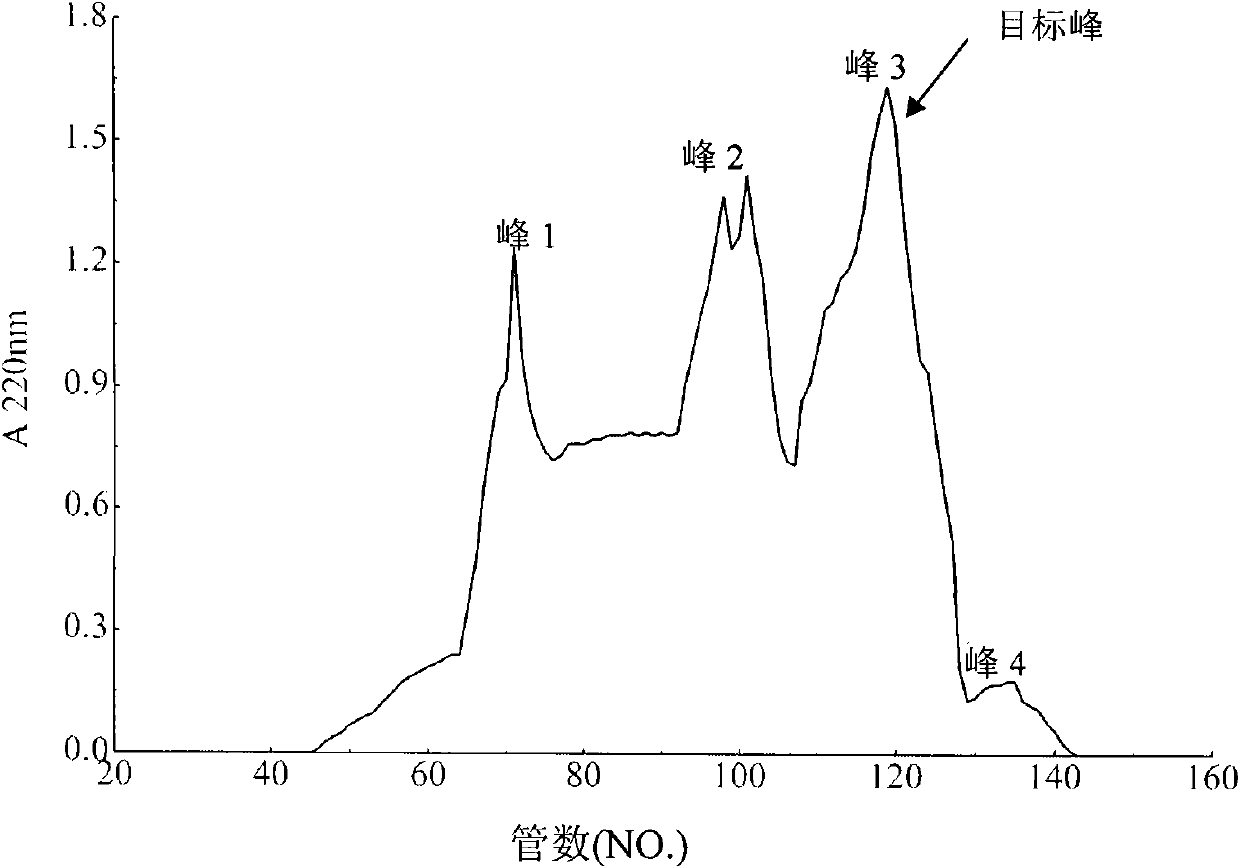

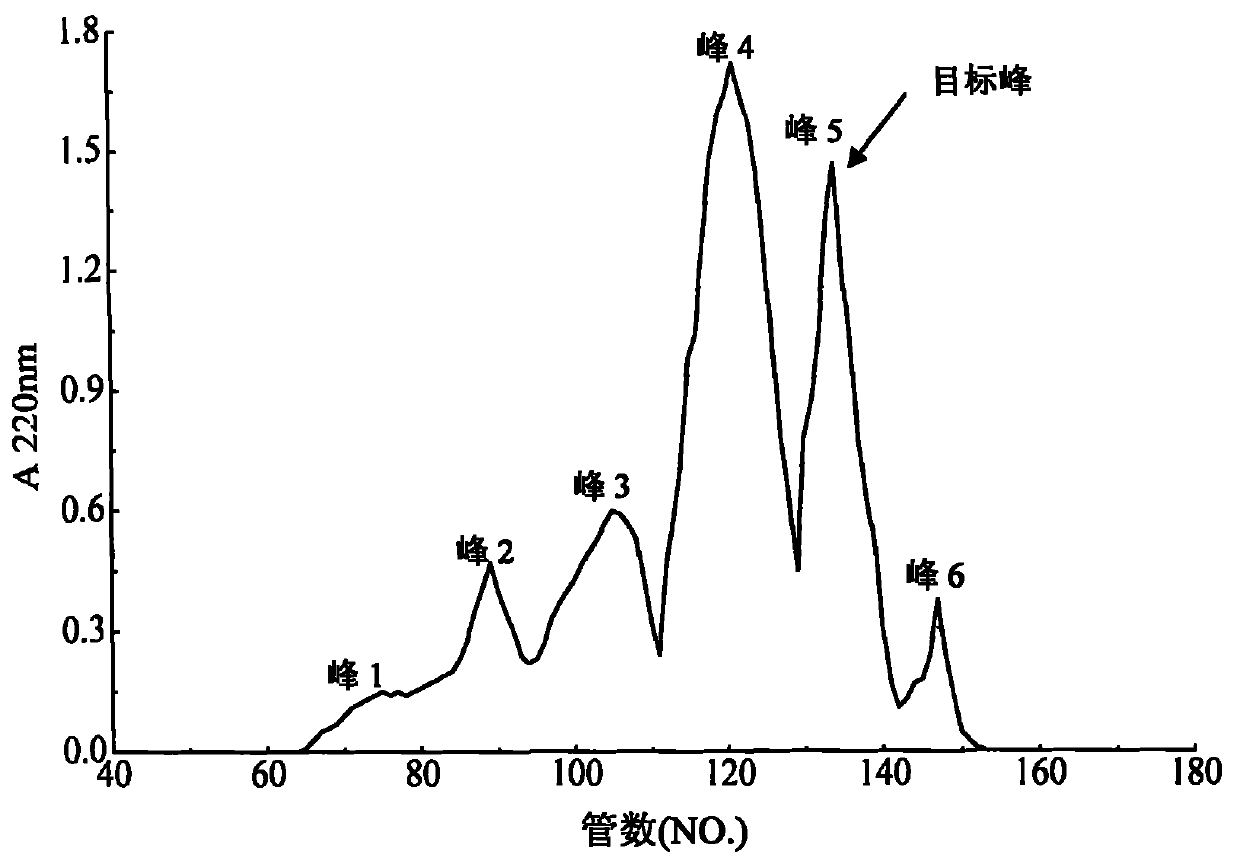

[0078] 4). The enzymatic hydrolysate obtained in step 3) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ic50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com