High-power emulsion explosive and preparation method thereof

A technology of emulsified explosives and power, applied in the direction of explosives, etc., can solve the problems of consuming steam or electric energy, affecting safety production, prolonging the dissolution time of water phase, etc., to achieve the goal of increasing the explosion temperature and specific volume, improving the working ability and reducing project investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

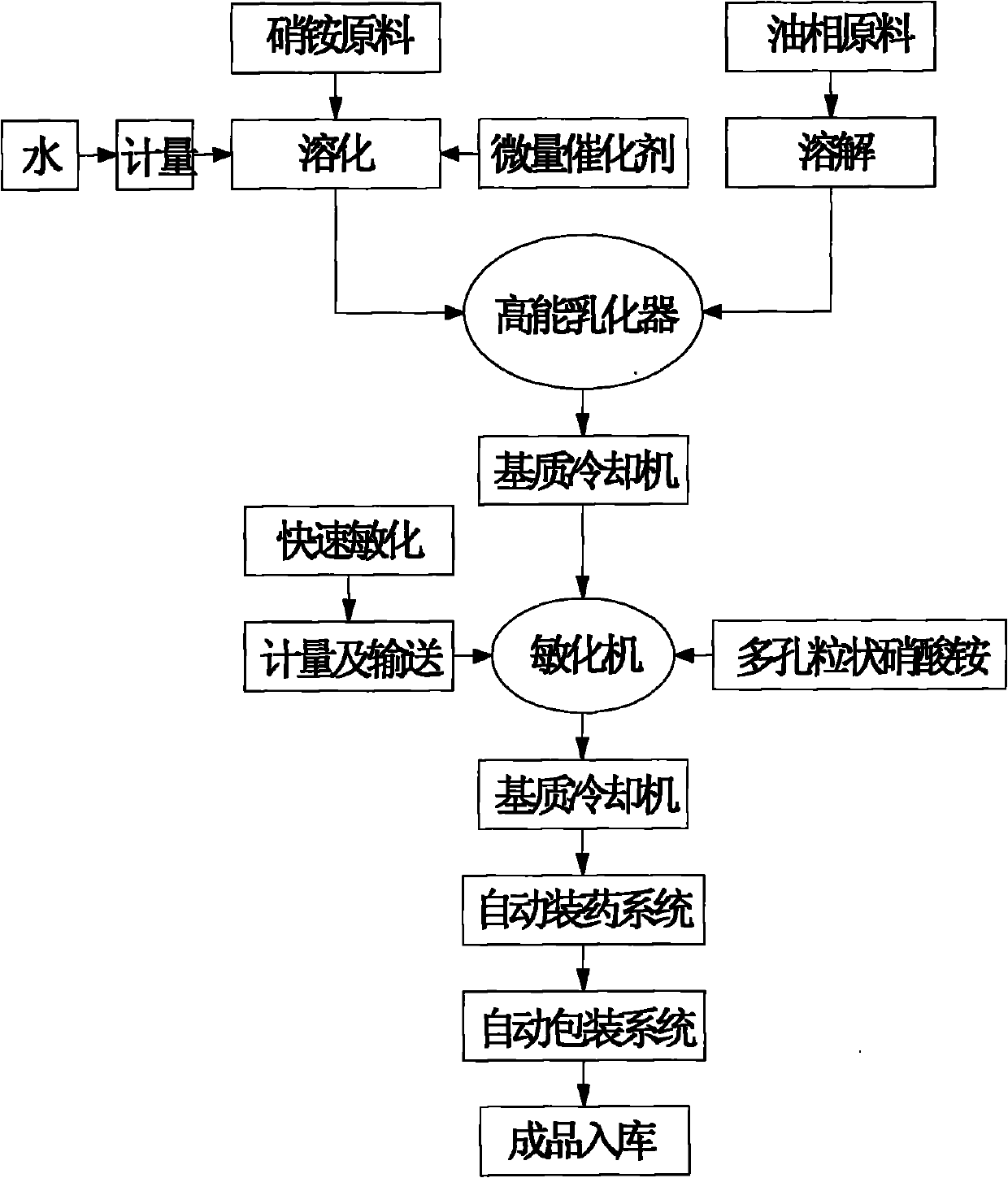

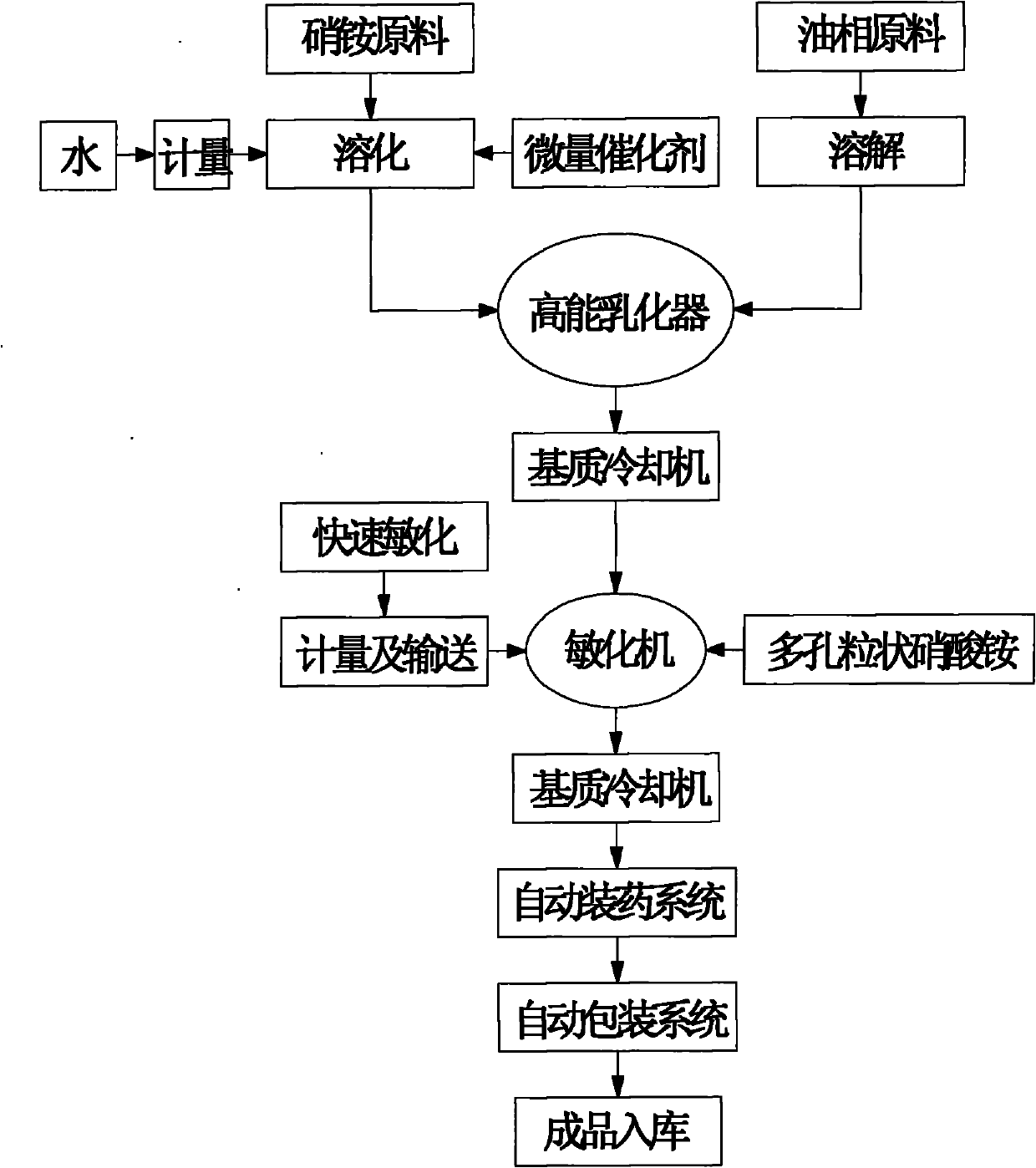

Method used

Image

Examples

Embodiment 1

[0024] Add 9 kg of tap water into the water phase dissolving tank and heat up to 100°C, power 3KW, speed 1420 rpm, then add 80 kg of ammonium nitrate, 3.5 kg of sodium nitrate, and 1 kg of urea to dissolve under heating. When the temperature rises to 100°C, Insulation for standby, the dissolution time is 35 minutes; 1.5 kg of paraffin and 3 kg of composite oil phase are sequentially added to the oil phase dissolution tank (1.5KW, 1430 rpm) to heat up, the dissolution temperature is 85 ° C, and the dissolution time is 35 minutes. Add 2.0 kilograms of modified Span-80 emulsifiers 10 minutes before use, and keep warm for subsequent use. The modified Span-80 emulsifiers are the compound of 0.8 kilograms of soybean flour emulsifiers and 1.2 kilograms of Span-80 emulsifiers; , After the oil phase material is filtered, the water phase conveying equipment and the oil phase conveying system are sent to the emulsifier for emulsification, the power is 15KW, the speed is 1470 rpm, and then...

Embodiment 2

[0026] Add 11 kg of tap water to the water phase dissolution tank to raise the temperature, then add 78 kg of ammonium nitrate, 5 kg of sodium nitrate, and 0.3 kg of urea to dissolve under heating. Add paraffin wax and 2.7 kg of composite oil phase to the oil phase dissolving tank in sequence to raise the temperature, the dissolving temperature is 90°C, and the dissolving time is 30 minutes. Span-80 emulsifier is a compound of 0.9 kg of soybean flour emulsifier and 0.6 kg of Span-80 emulsifier; after filtering the above-mentioned water phase and oil phase materials, the water phase conveying equipment and oil phase conveying system are sent to the emulsifier Carry out emulsification, and then send it to the cooling machine with a latex delivery pump for automatic cooling. Sodium nitrate, 750 grams of ammonium nitrate, 985 grams of water, gram of phosphoric acid, 7.5 grams of thiourea, and 10 kilograms of porous granular ammonium nitrate are mixed uniformly through a continuous...

Embodiment 3

[0028] Add 9 kg of tap water to the water phase dissolving tank to raise the temperature, then add 77 kg of ammonium nitrate, 5 kg of sodium nitrate, and 2 kg of urea to heat and dissolve. Add paraffin wax and 3.5 kg of composite oil phase to the oil phase dissolving tank in order to raise the temperature, the dissolving temperature is 90°C, and the dissolving time is 30 minutes. Span-80 emulsifier is a mixture of 1 kg of soybean flour emulsifier and 1 kg of Span-80 emulsifier; after filtering the above-mentioned water phase and oil phase materials, the water phase conveying equipment and oil phase conveying system are sent to the emulsifier Carry out emulsification, and then send it to the cooling machine with a latex delivery pump for automatic cooling. Sodium nitrate, 750 grams of ammonium nitrate, 985 grams of water, 7.5 grams of phosphoric acid, 7.5 grams of thiourea, and 13.3 kilograms of granular ammonium nitrate are mixed uniformly through a continuous sensitization ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com