Special silicon brick

A kind of silicon molybdenum brick, a special technology, applied in the field of refractory bricks, can solve the problems of short service life, reduce the economic benefits and production efficiency of cement manufacturers, and increase the manufacturing cost of the rotary kiln of the dry-process cement production line, so as to improve the thermal shock resistance, Good high temperature wear resistance and improved high temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

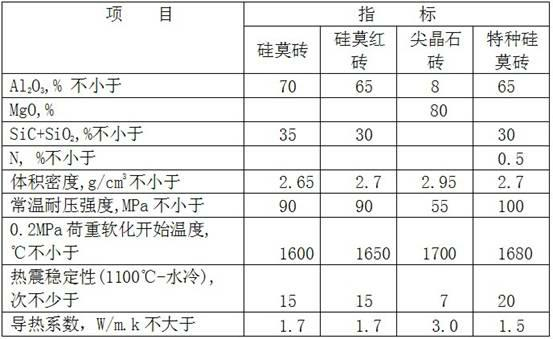

Image

Examples

Embodiment 1

[0030] The special silicon molybdenum brick described in the present invention is prepared from the following main materials, auxiliary materials and binders:

[0031] a, the weight percent distribution ratio of the main material is:

[0032] Bauxite clinker:

[0033] Particle size 4mm, 20%; Particle size 2mm, 20%; Particle size 1mm, 15%;

[0034] The physicochemical index of described bauxite clinker is: Al 2 o 3 ≥88%; Fe 2 o 3 ≤1%; impurity ≤1%; bulk density ≥3.3g / cm 3 ;Water absorption ≤1%;

[0035] Silicon carbide: particle size 1mm, 20%;

[0036] The physical and chemical performance index of the silicon carbide is: SiC≥97% Fe 2 o 3 ≤0.5%; F, C≤0.25%;

[0037] B, the weight percent distribution ratio of described auxiliary material is:

[0038] Fused corundum: 5%, finer than 325 mesh;

[0039] The physical and chemical performance index of the fused corundum is: Al 2 o 3 ≥99%; Fe 2 o 3 ≤0.15%; bulk density ≥3.5g / cm 3 ;

[0040] α-Sialon: 7%, finer than 2...

Embodiment 2

[0053] The special silicon molybdenum brick described in the present invention is prepared from the following main materials, auxiliary materials and binders:

[0054] a, the weight percent distribution ratio of the main material is:

[0055] Bauxite clinker:

[0056] Particle size 3mm, 22%; Particle size 1.5mm, 22%; Particle size 1mm, 16%;

[0057] The physicochemical index of described bauxite clinker is: Al 2 o 3 ≥88%; Fe 2 o 3 ≤1%; impurity ≤1%; bulk density ≥3.3g / cm 3 ;Water absorption ≤1%;

[0058]Silicon carbide: particle size 0.88mm, 10%;

[0059] The physical and chemical performance index of the silicon carbide is: SiC≥97% Fe 2 o 3 ≤0.5%; F, C≤0.25%;

[0060] B, the weight percent distribution ratio of described auxiliary material is:

[0061] Fused corundum: 8%, finer than 325 mesh;

[0062] The physical and chemical performance index of the fused corundum is: Al 2 o 3 ≥99%; Fe 2 o 3 ≤0.15%; bulk density ≥3.5g / cm 3 ;

[0063] β-Sialon: 10%, finer t...

Embodiment 3

[0073] The special silicon molybdenum brick described in the present invention is prepared from the following main materials, auxiliary materials and binders:

[0074] a, the weight percent distribution ratio of the main material is:

[0075] Bauxite clinker:

[0076] Particle size 2.1mm, 23%; Particle size 1.1mm, 25%; Particle size 0.6mm, 19%;

[0077] The physicochemical index of described bauxite clinker is: Al 2 o 3 ≥88%; Fe 2 o 3 ≤1%; impurity ≤1%; bulk density ≥3.3g / cm 3 ;Water absorption ≤1%;

[0078] Silicon carbide: particle size 0.5mm, 10%;

[0079] The physical and chemical performance index of the silicon carbide is: SiC≥97% Fe 2 o 3 ≤0.5%; F, C≤0.25%;

[0080] B, the weight percent distribution ratio of described auxiliary material is:

[0081] Fused corundum: 9%, finer than 325 mesh;

[0082] The physical and chemical performance index of the fused corundum is: Al 2 o 3 ≥99%; Fe 2 o 3 ≤0.15%; bulk density ≥3.5g / cm 3 ;

[0083] β-Sialon or α-Sial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com