A new type of floating solid foam row rod and its preparation method

A technology of soaking rods and solids, which is applied to chemical instruments and methods, mining fluids, earth drilling and mining, etc., can solve the problems of slow dissolution rate, small contact surface, inconvenient storage and use, etc., and achieves the simple and easy preparation method, Enhance foam stability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This example provides the components and proportions of several floatable solid foam discharge sticks, and also provides the preparation method of each foam discharge stick.

[0047] (1) Floatable solid bubble row stick SRP-1

[0048] The components and their proportions are: 50 kg of dodecyl ethoxy sulfobetaine, 15 kg of cocoic acid monoethanolamide, 10 kg of thiourea, 5 kg of sodium chloride, 3 kg of polyvinyl alcohol, and 2 kg of sodium benzoate.

[0049] The preparation method of floating solid bubble row stick SRP-1:

[0050] Step 1: Put 50 kg of lauryl ethoxy sulfobetaine, 15 kg of cocoic acid monoethanolamide, and 10 kg of thiourea into a container, mix well, heat to 50°C, and heat-preserve and dry for 3 hours.

[0051] Step 2: Add 5 kg of sodium chloride, 3 kg of polyvinyl alcohol, and 2 kg of sodium benzoate into the container of step 1, mix evenly, start heating, gradually heat up to 80 ° C, and keep warm for 5 hours until the material is dried;

[0052] Ste...

Embodiment 2

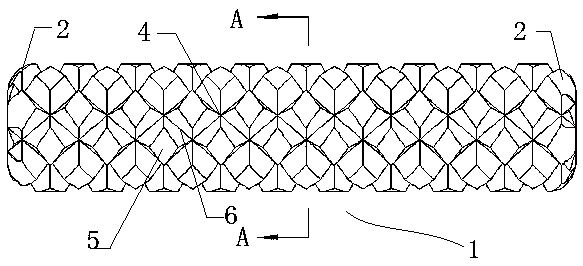

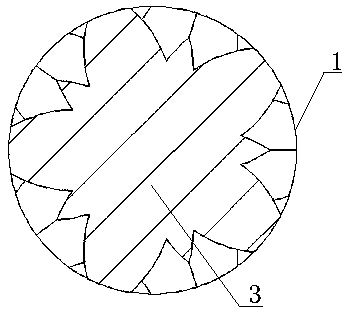

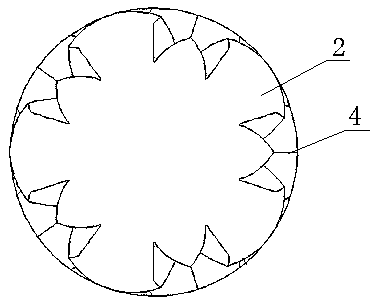

[0078] The above-mentioned floatable solid bubble-discharge sticks SRP-1, SRP-2, SRP-3, SRP-4, and SRP-5 were prepared according to the preparation method described in Example 1 to prepare bubble-discharge sticks. For the structure of these sticks see Figure 1 to Figure 4 .

[0079] Such as figure 1 and 4 As shown, this embodiment provides a kind of floating foam row rod for gas recovery in oil and gas fields. In terms of overall appearance, the bubble discharge rod is similar to the existing foam discharge rod, and is a cylindrical rod 1 made of foam discharge agent. The difference is that arc-shaped transition sections 2 are provided at both ends of the bubble discharge stick in this embodiment, and threads 4 are provided on the surfaces of the cylindrical rod body 1 and the arc-shaped transition section 2 . It should be noted that the cylindrical rod body 1 and the arc-shaped transition sections 2 at both ends are of an integral structure.

[0080] In this embodiment,...

Embodiment 3

[0084] In this example, the performance of the floatable solid bubble discharge sticks SRP-1, SRP-2, SRP-3, SRP-4, and SRP-5 was tested, and compared with the performance of the commercially available bubble discharge stick UT-6. Refer to industry standard SY / T5761-1995, design performance test. The preparation of mineralized water with different concentrations used in this embodiment is as follows.

[0085] Industry standard water type: weigh 12.5g NaCl and 2.5g CaCl 2 Dissolve it in a clean small beaker, then pour it into a 250ml volumetric flask and make it into an aqueous solution with a salinity of 60g / L.

[0086] NaHCO 3 Water type: weigh 1.25g NaHCO 3 Dissolve it in a clean small beaker, then pour it into a 250ml volumetric flask and make it into an aqueous solution with a salinity of 5g / L.

[0087] CaCl 2 Water type: weigh 15g NaCl and 27.5g CaCl 2 Dissolve it in a clean small beaker, then pour it into a 250ml volumetric flask and make it into an aqueous solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com