Full automatic ceramic tile packaging equipment

A kind of packaging equipment, fully automatic technology, applied in the field of packaging, can solve the problems of increasing enterprise cost, unreliable work, cumbersome work, etc., and achieve the effects of reducing equipment failure rate, improving production efficiency and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

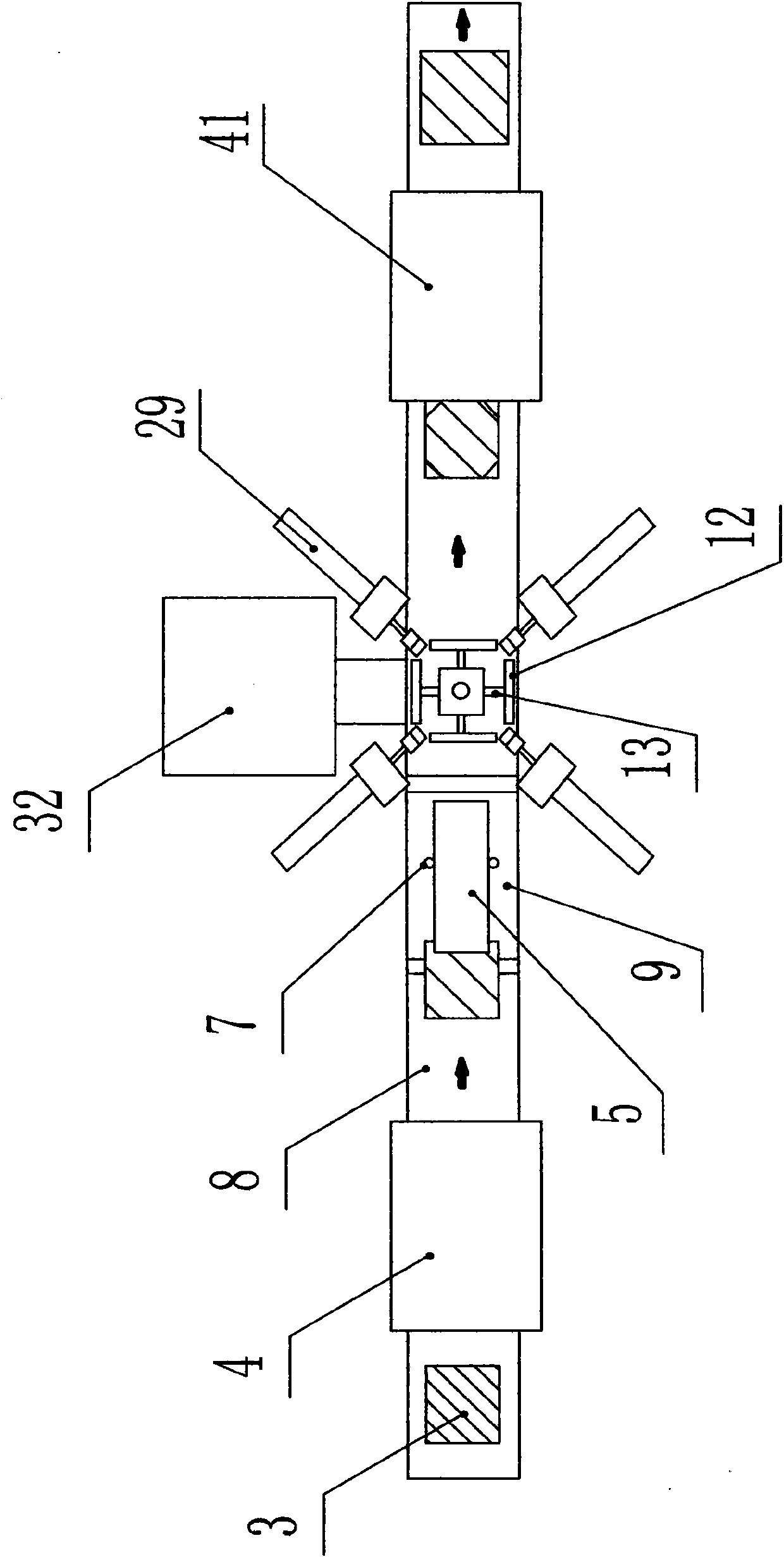

[0036] As shown in the figure: the produced tiles are transported to the tile turning equipment, and the tile turning equipment turns the transported tiles into a sequence of one positive and one reverse, and the adjacent tiles on the conveyor belt are always positive Bottom, face-down tiles are always face-up on adjacent tiles on the transport belt. In this way, in the subsequent tile stacking process, the front of the tiles will not be worn down. The ceramic tile flipping device belongs to the prior art and can be purchased on the market, so it will not be repeated here.

[0037] Such as image 3As shown, a stacking brick conveyor belt 8 is set in front of the upper brick conveyor belt 1, a stacking brick traction frame 6 is set above the brick stacking conveyor belt 8, and the horizontal movement control device 5 is a chain sprocket drive. The stacking brick traction frame 6 is fixed on the chain and is driven by the chain, and the stop bar 7 is fixed on the frame, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com