Universal pushing and pulling mechanism for stretch forming machine

A technology of stretch forming, push-pull mechanism, applied in metal processing equipment, feeding device, positioning device, etc., can solve the problems of uneven distribution of tensile stress and tensile strain of the plate, complicated control system design, and expensive equipment. The effect of improving material utilization, reducing process allowance and reasonable loading path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

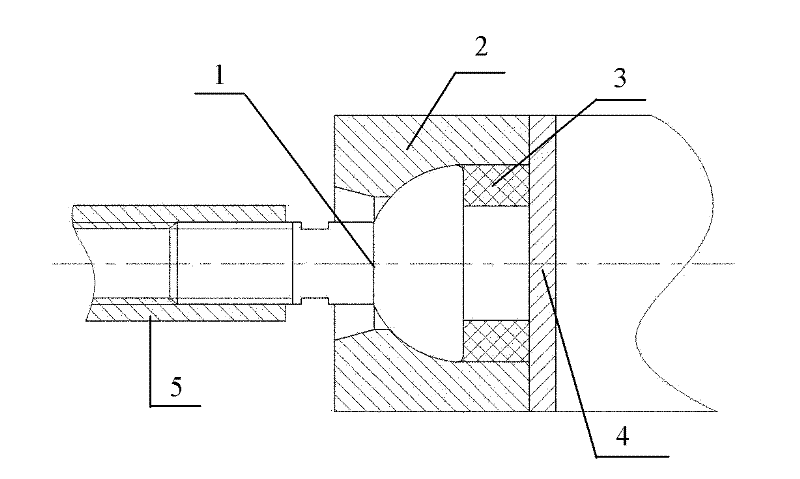

[0020] figure 1 It is a cross-sectional view when a ball-joint connecting rod 1 with a hemispherical head at one end is directly connected to the clamping frame 2. An annular polyurethane pad 3 is arranged at the hemispherical end, and the annular polyurethane pad 3 is installed in the coupling hole of the clamping frame 2 by the baffle plate 4 through screws. The non-ball end of the ball-joint connecting rod is connected with the pulling mechanism through the screw thread and the rod-type coupling body 5 .

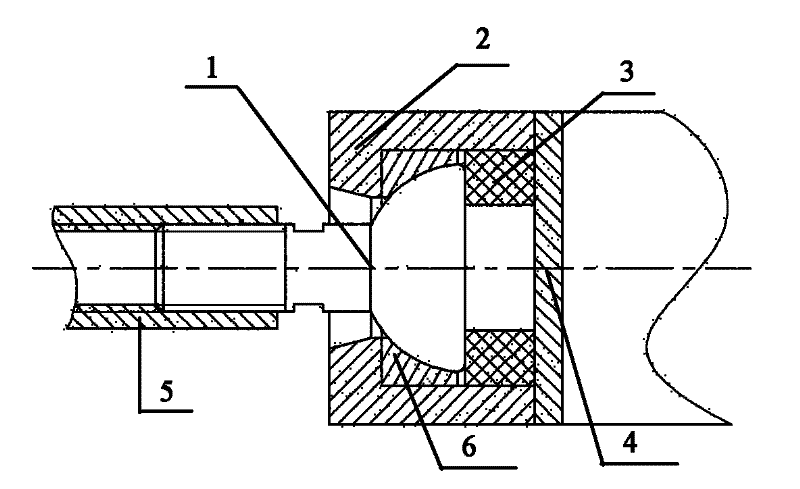

[0021] figure 2 It is a cross-sectional view when a ball joint rod 1 with a hemispherical head at one end is connected to a clamping frame 2 through a bearing bush 6 with a hemispherical dimple. The material of the bearing bush is a sliding bearing material such as copper or nylon. An annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com