Micro-electromechanical device and method for fabricating the same

A micro-electromechanical and manufacturing method technology, which is applied in the direction of manufacturing micro-structure devices, micro-electronic micro-structure devices, circuits, etc., to achieve the effect of narrow gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

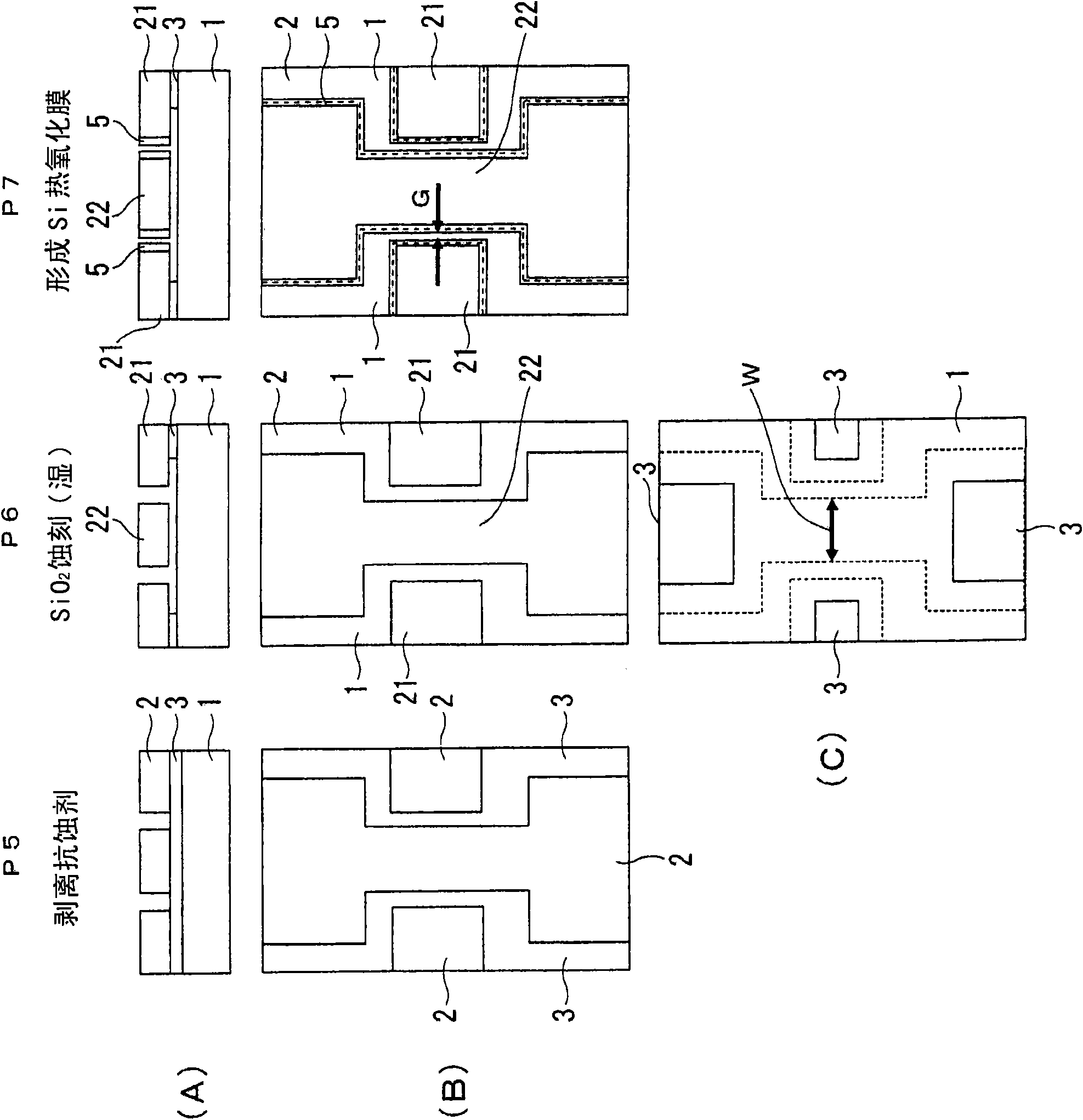

[0039] Below, with reference to the accompanying drawings, based on the Figure 6 The manner in which the MEMS resonator is shown is implemented to illustrate the invention.

[0040] figure 1 and figure 2 Steps P1 to P7 for forming the resonator and the left and right electrodes of the MEMS resonator of the present invention are shown. In addition, in figure 1 and figure 2 Among them, (A) is a longitudinal sectional view, and (B) and (C) are top views.

[0041] First, in figure 1 In step P1 of , prepare to laminate SiO on the surface of Si layer 1 to be the substrate 2 layer 3 and Si layer 2 to form an SOI wafer.

[0042] Next, in step P2 , resist 4 is applied to the surface of Si layer 2 . Then, in step P3, the resist 4 is exposed and developed using an i-line exposure machine to form a groove pattern having the gap G'. Here, the limit of the gap G' is 0.35 µm.

[0043] Next, in step P4 , dry etching is performed on the Si layer 2 to form the grooves 20 on the S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com