Method for repairing open circuit of thick copper lead wire and repairing structure thereof

A technology of copper wire and copper layer, which is applied in the direction of printed circuit, printed circuit manufacturing, conductive pattern reinforcement, etc., can solve the problems of poor appearance quality of printed boards, inability to repair thick copper wire disconnection, insufficient mechanical strength, etc., to achieve The effect of fast speed and meeting the requirements of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

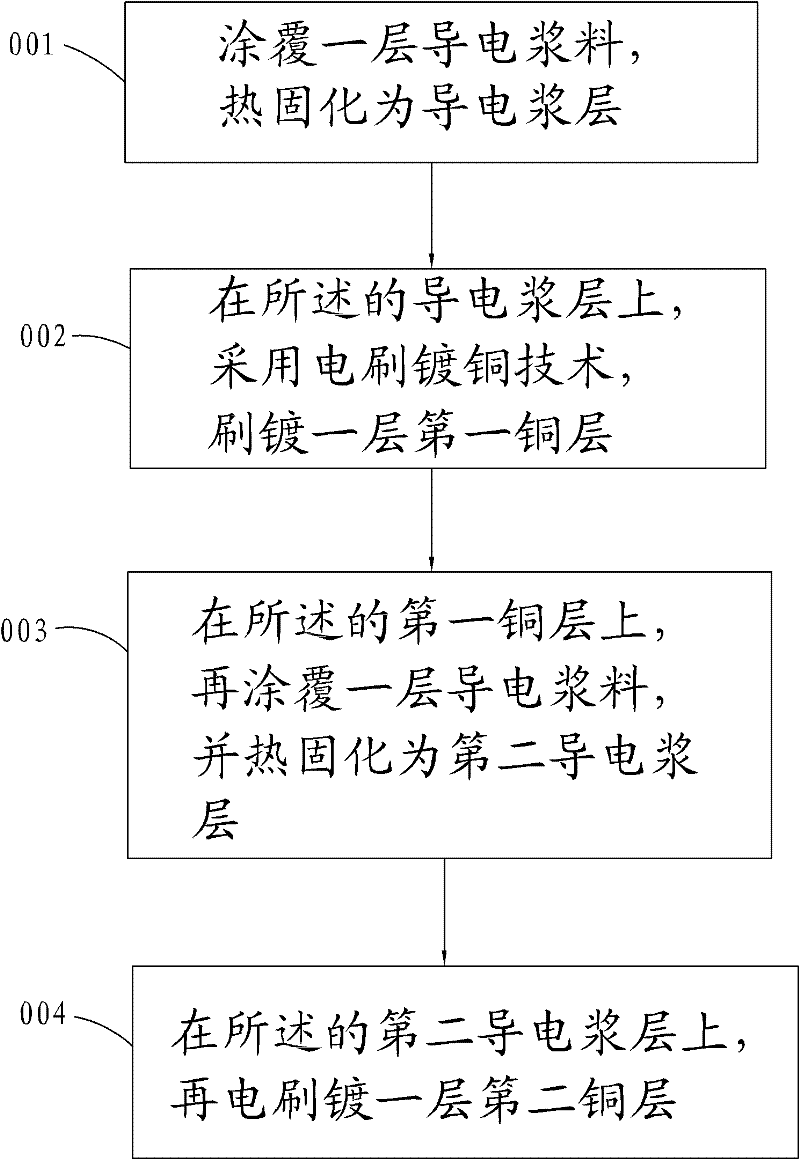

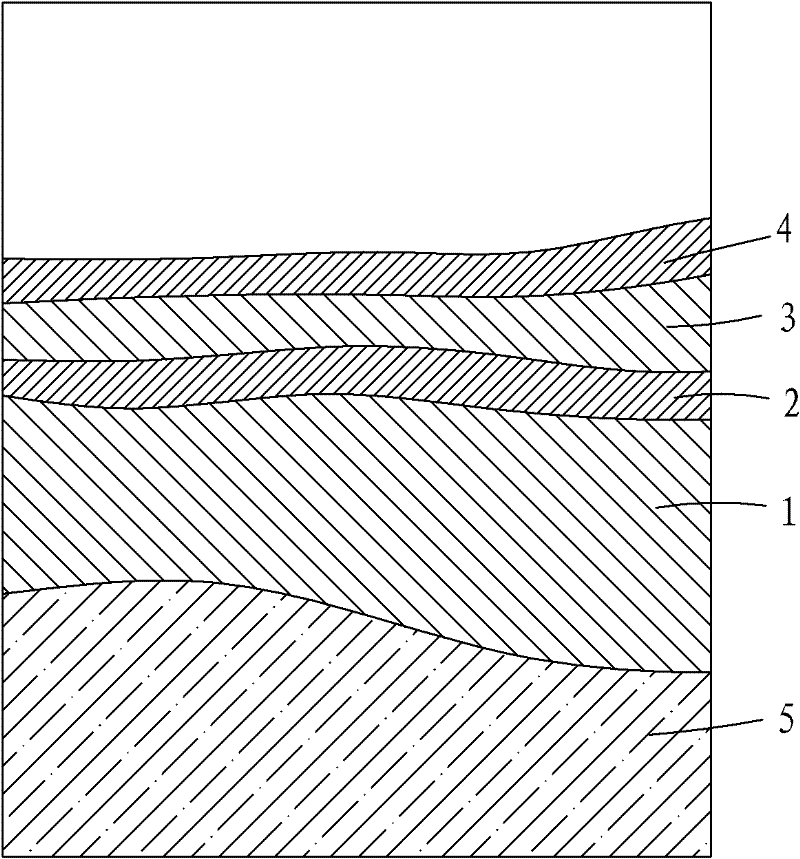

[0026] refer to figure 1 with figure 2 , the embodiment of the present invention will be described in detail.

[0027] Such as figure 1 , is an embodiment of a method for repairing a thick copper wire disconnection of the present invention. In the first step, at first, a layer of conductive paste is coated on the broken or incomplete position of the thick copper wire, and the conductive paste is silver paste. The silver paste is thermally cured to form a first silver paste layer, which serves as the basis for the conductive layer and subsequent repairs. The second step is to brush-plate a layer of first copper layer on the first silver paste layer. The first copper layer is a copper layer brush-plated with copper nitrate solution. The third step is to coat a layer of conductive paste on the first copper layer, the conductive paste is silver paste, and dry the silver paste to form the second silver paste layer. In the fourth step, a second copper layer is brush-plated on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com