Method for repairing broken circuit or mutilation of copper bonding pad and repair structure thereof

An incomplete and brazing technology, which is applied in the field of circuit break repair of printed circuit boards, can solve problems such as non-solderability, poor appearance quality of printed circuit boards, contact, etc., and achieve fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

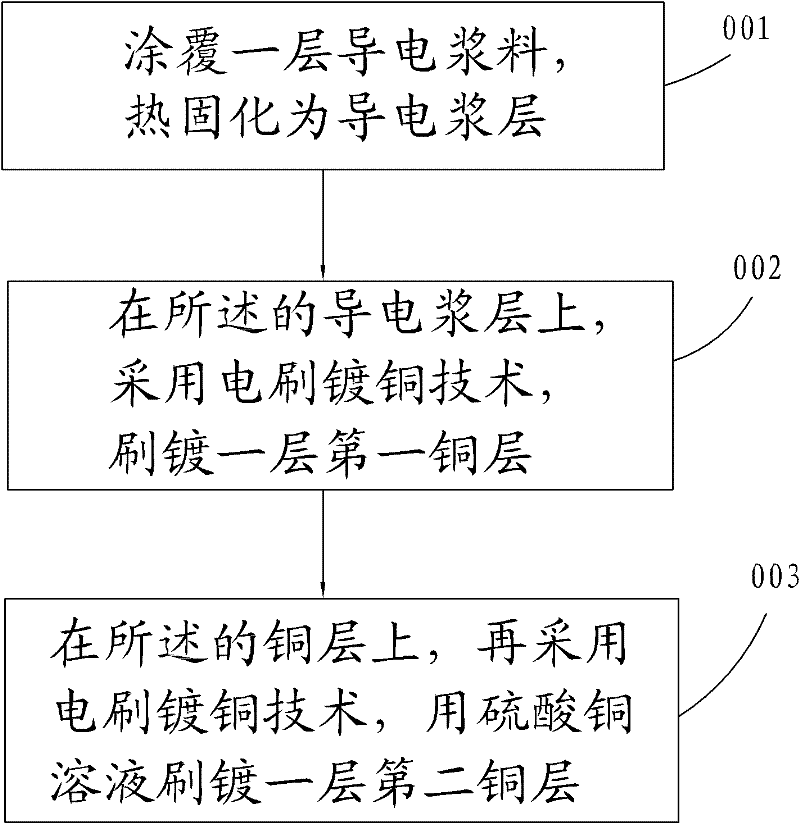

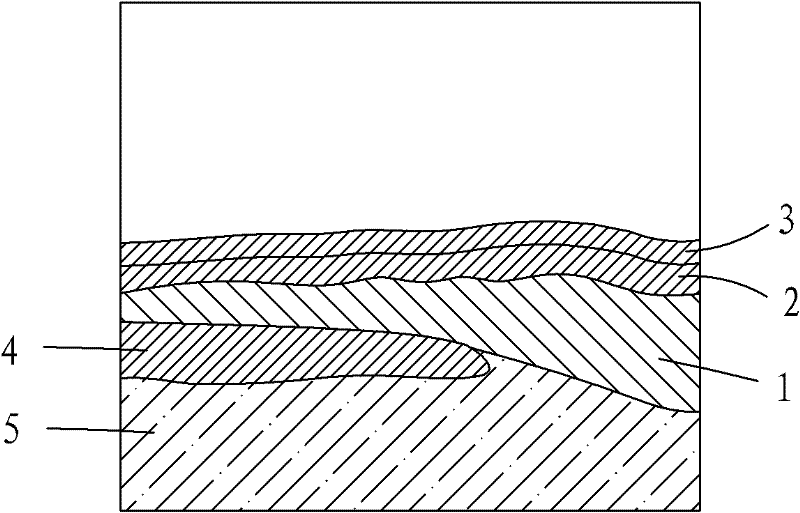

[0023] See 1 and figure 2 , to describe the embodiment of the present invention in more detail.

[0024] Such as figure 1 , is a flow chart of a copper pad disconnection or incomplete repair method of the present invention. The first step is to first coat a layer of conductive paste accounting for 1 / 3 of the total repair thickness on the copper pad wire disconnection position or incomplete part as the base layer, the conductive paste is silver paste, and the silver paste After being baked, it is thermally cured into a silver paste layer, and this layer of silver paste layer is used as the basis for the conductive layer and subsequent repairs. In the second step, on the silver paste layer, a layer of first copper layer is brush-plated. The first copper layer is an electroplating potion using copper nitrate solution, and a layer of copper layer is brush-plated. The first copper layer accounts for about 1 / 3 of the total repair thickness. In the third step, on the basis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com