Shale oil single-stage serial hydrocracking technology method

A technology for hydrocracking and shale oil, applied in hydrotreating process, hydrocarbon oil cracking, petroleum industry and other directions, can solve the problems of affecting the cracking effect, reducing the acid center, unable to fully exert the effect of catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

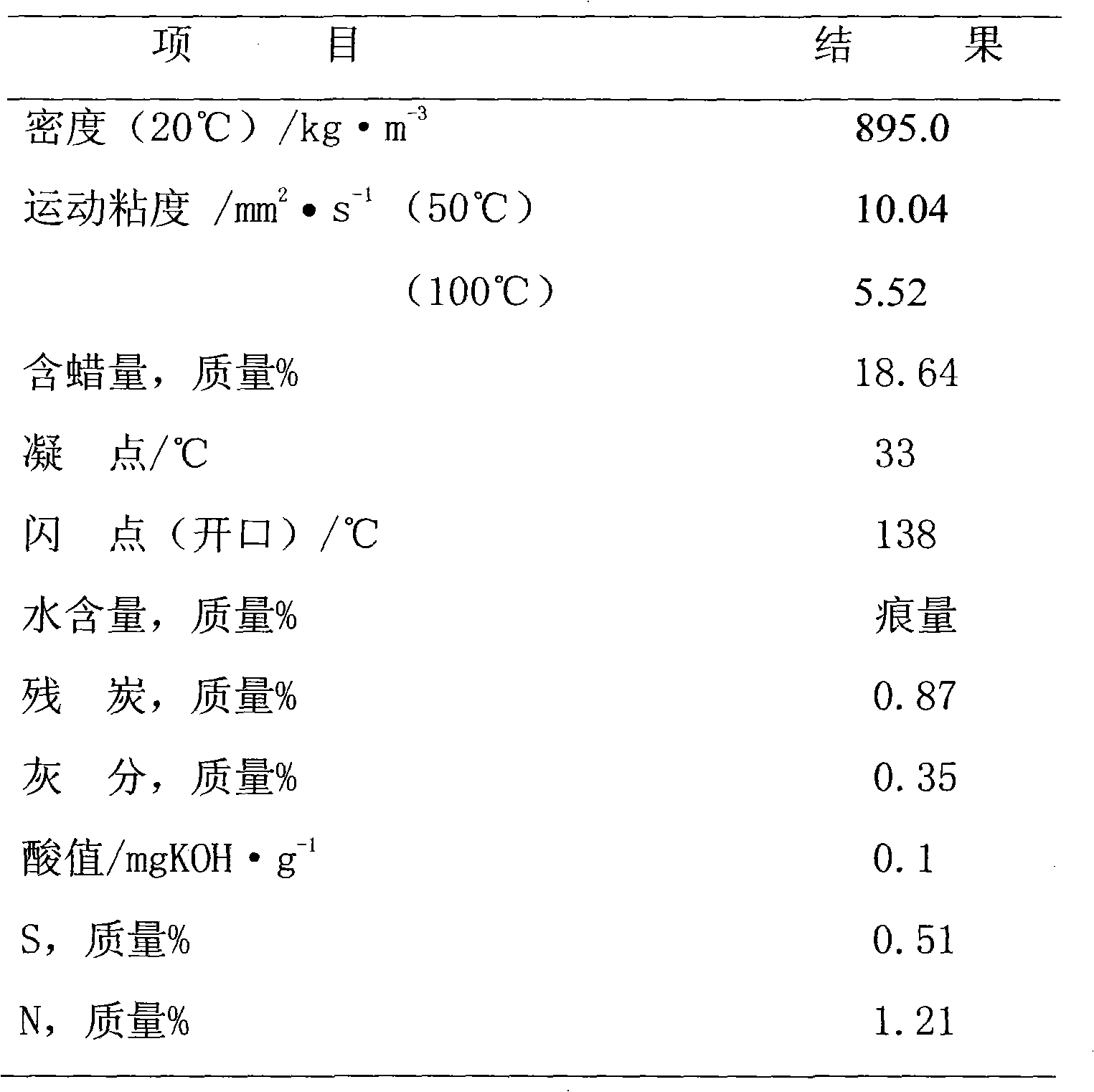

Image

Examples

Embodiment 1

[0019] The hydrofining catalyst is FF-26, the hydrocracking catalyst is FC-14, at a reaction temperature of 360°C, a reaction pressure of 8.0MPa, and a refining volume space velocity of 0.3h -1 , hydrogen oil ratio 1000:1, cracking volume space velocity 0.3h -1 , operating under the condition of hydrogen oil ratio of 400:1. The hydrocracking catalyst adopts two catalyst beds, each catalyst bed accounts for 50% of the total catalyst volume, the upper part uses FC-14B, and the lower part uses FC-14A. The conventional process refers to the hydrocracking operation in which the hydrorefining reaction effluent enters the top of the hydrocracking reactor, and gas-liquid is collected and flows downward. The reaction results are shown in Table 2.

[0020] Table 2 Example 1 data

[0021] project

Embodiment 2

[0023] At a reaction temperature of 420°C, a reaction pressure of 10.0MPa, and a refined volumetric space velocity of 0.5h-1 , hydrogen oil ratio 800:1, cracking volume space velocity 0.8h -1 , operating under the condition of hydrogen oil ratio of 300:1. The hydrocracking catalyst is a mixture of FC-14B and FC-14A at a volume ratio of 1:1. The results are shown in Table 3.

[0024] Table 3 Example 2 data

[0025] project

Embodiment 3

[0027] At a reaction temperature of 390°C, a reaction pressure of 15.0MPa, and a refined volumetric space velocity of 0.8h -1 , hydrogen oil ratio 800:1, cracking volume space velocity 0.5h -1 , operating under the condition of hydrogen oil ratio of 150:1. The hydrocracking catalyst is FC-14A. The results are shown in Table 4.

[0028] Table 4 Example 3 data

[0029] project

[0030] The comparative test data show that the application of the technology of the invention avoids the influence of ammonia on the hydrocracking catalyst, the cracking effect is obvious, and the yield of light oil is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com