Preparation method of nano-fiber poly-aniline

A technology for nanofibers and polyaniline, which is applied in the field of preparing nanofiber polyaniline by electrochemical methods, can solve the problems of poor stability and decreased activity of PANI, and achieve the effects of good reproducibility, short reaction time and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1, dissolving 9.3598g of aniline monomer in 250ml of aqueous solution to form aniline aqueous solution A with a molar concentration of 0.4mol / L;

[0027] Step 2, dissolving the concentrated sulfuric acid of 50.865g in the water of 500ml is configured into the sulfuric acid aqueous solution B of 1.0mol / L;

[0028] Step 3. At room temperature, take 20ml of solution A and 20ml of solution B into a beaker and stir evenly;

[0029] Step 4, using a three-electrode system (the counter electrode is a platinum sheet, and the working electrode is a 0.5cm 2 Platinum sheet, saturated calomel electrode as reference electrode). Set the unipolar pulse signal as follows: pulse voltage = 1.0V, on-time 0.4s, pulse cut-off time 0.4s, current is zero (open circuit voltage), pulse times = 375;

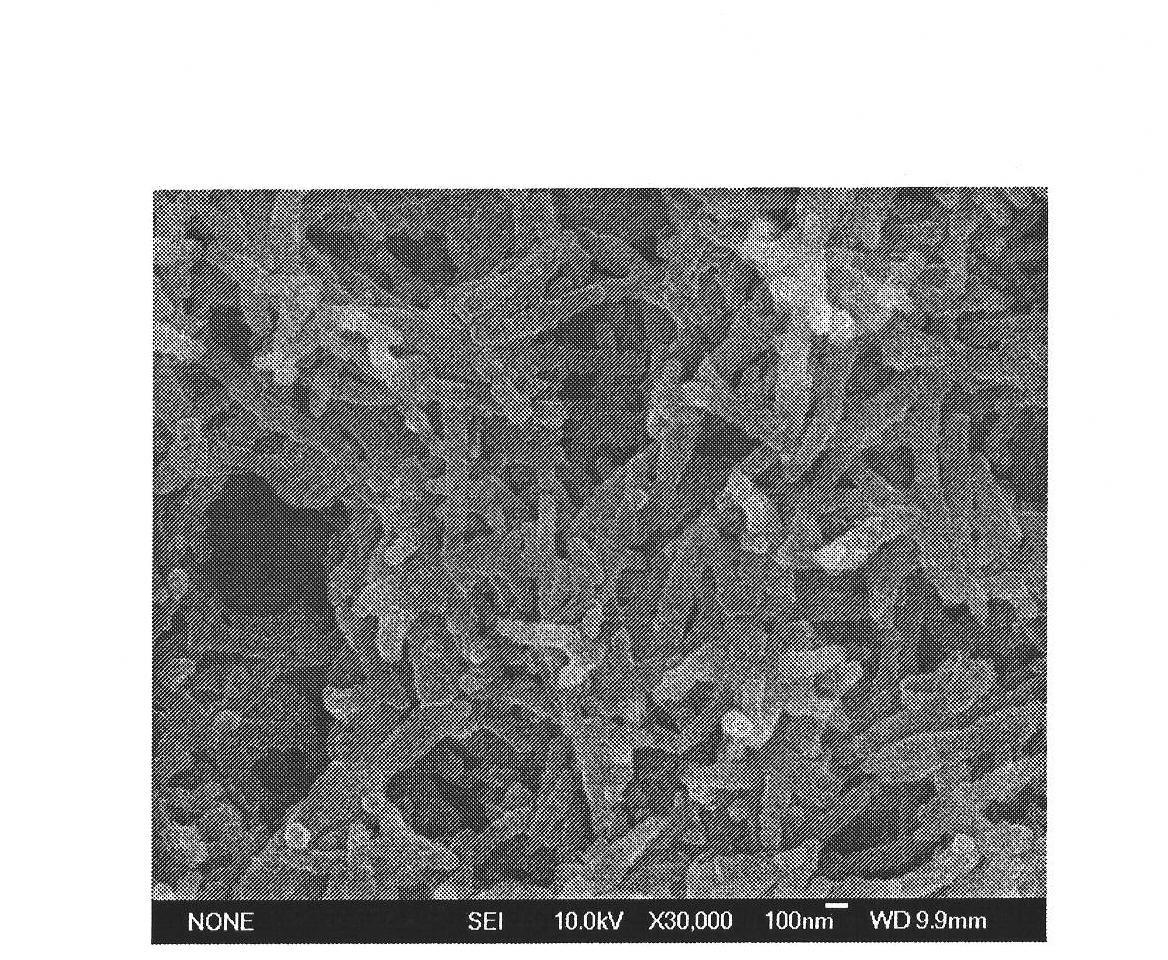

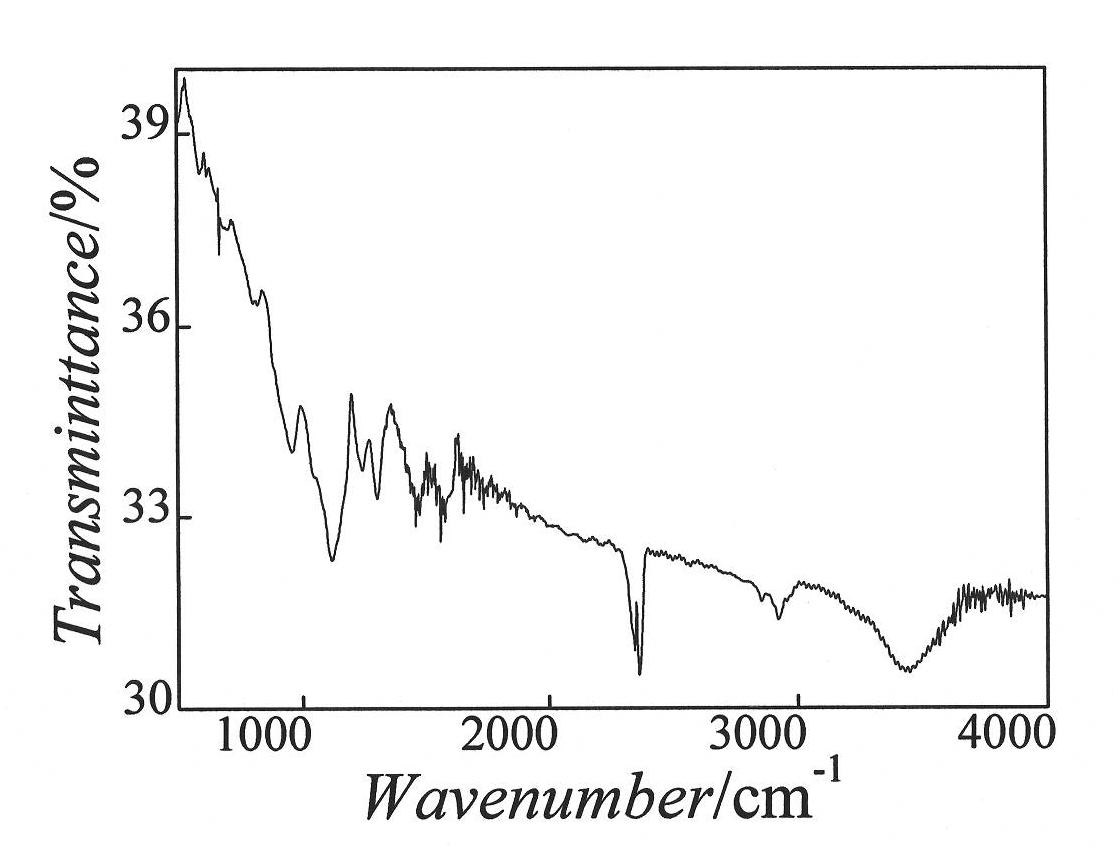

[0030] Step 5, take out the prepared polyaniline membrane electrode, rinse it with distilled water, and dry it at room temperature for 48 hours to obtain polyaniline nanofibers doped with sul...

Embodiment 2

[0032] (1) 9.3598g of aniline monomer is dissolved in 250ml of aqueous solution to be configured as an aniline aqueous solution A with a molar concentration of 0.4mol / L;

[0033] (2) The concentrated sulfuric acid of 50.865g is dissolved in the water of 500ml and is configured into the sulfuric acid aqueous solution B of 1mol / L;

[0034] (3) At room temperature, take 25ml of solution A and 25ml of solution B into a beaker and stir evenly;

[0035] (4) A three-electrode system is adopted (the counter electrode is a glassy carbon electrode, and the working electrode is 0.5cm 2 Platinum sheet, saturated calomel electrode as reference electrode). Set the unipolar pulse signal as: pulse voltage 0.9V, on-time 0.4s, pulse cut-off time 0.4s, current is zero (open circuit voltage), pulse times=400;

[0036] (5) Take out the prepared polyaniline membrane electrode, rinse it with distilled water, and dry it at room temperature for 48 hours to obtain polyaniline nanofibers doped with su...

Embodiment 3

[0038] (1) 11.6997g of aniline monomer is dissolved in 250ml of aqueous solution to be configured as an aniline aqueous solution A with a molar concentration of 0.5mol / L;

[0039] (2) The concentrated sulfuric acid of 50.865g is dissolved in the water of 500ml and is configured into the sulfuric acid aqueous solution B of 1mol / L;

[0040] (3) At room temperature, take 30ml of solution A and 30ml of solution B into a beaker and stir evenly;

[0041] (4) A three-electrode system is adopted (the counter electrode is platinum mesh, the working electrode is 0.5cm 2 Platinum sheet, saturated calomel electrode as reference electrode). Set the unipolar pulse signal as: pulse voltage 0.85V, on-time 0.4s, pulse cut-off time 0.3s, current zero (open circuit voltage), pulse times=500;

[0042] (5) Take out the prepared polyaniline membrane electrode and rinse it with distilled water, and dry it at room temperature for 48 hours to obtain polyaniline nanofibers doped with sulfuric acid, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com