Thermo-setting plastic pelleting method and device

A granulation device and thermosetting technology, applied in the direction of coating, etc., can solve the problems of uneven thermosetting plastic particles and excessive dust, and achieve the effect of uniform thermosetting plastic particles, reducing dust, and benefiting the environment and workers' health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

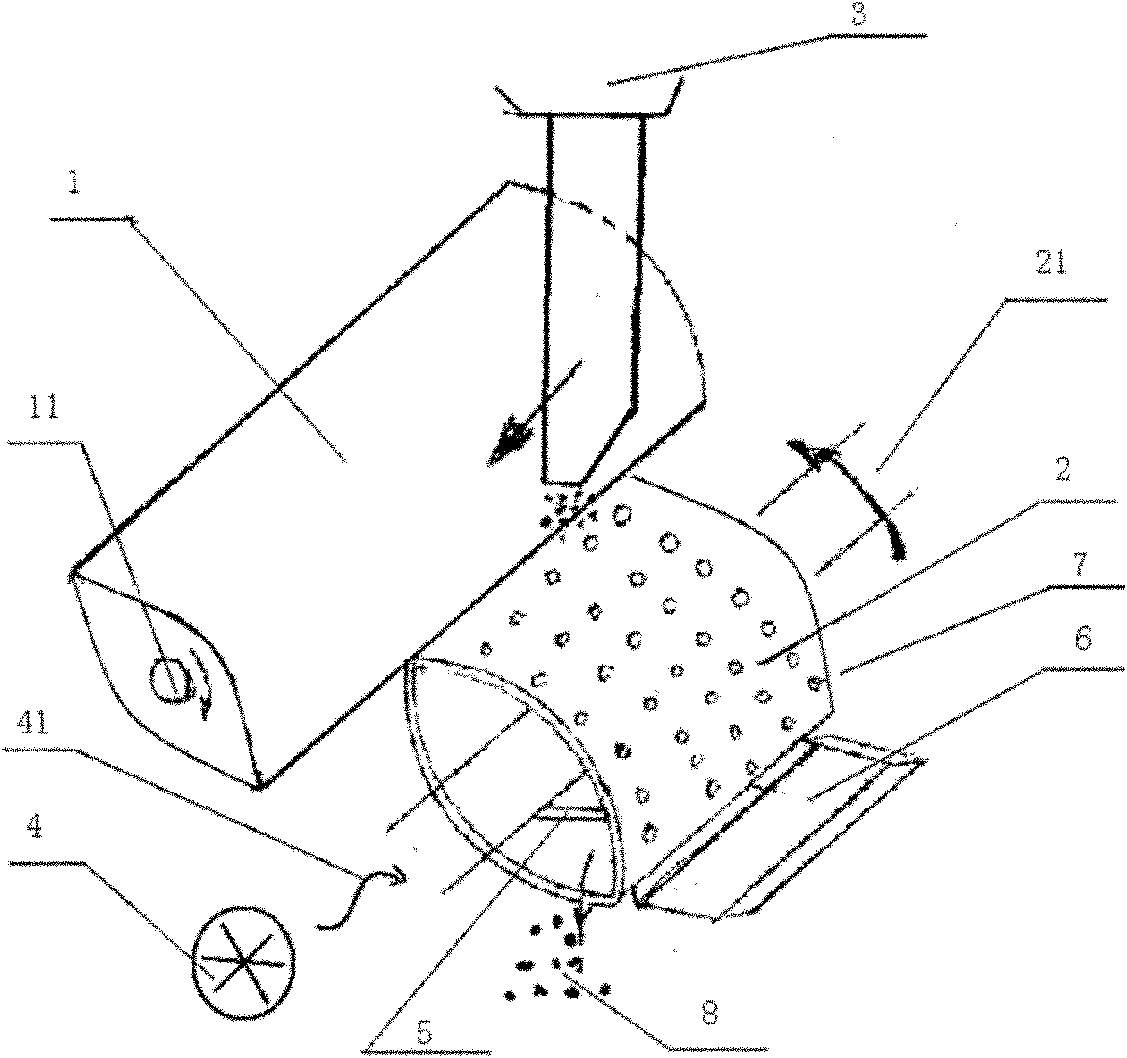

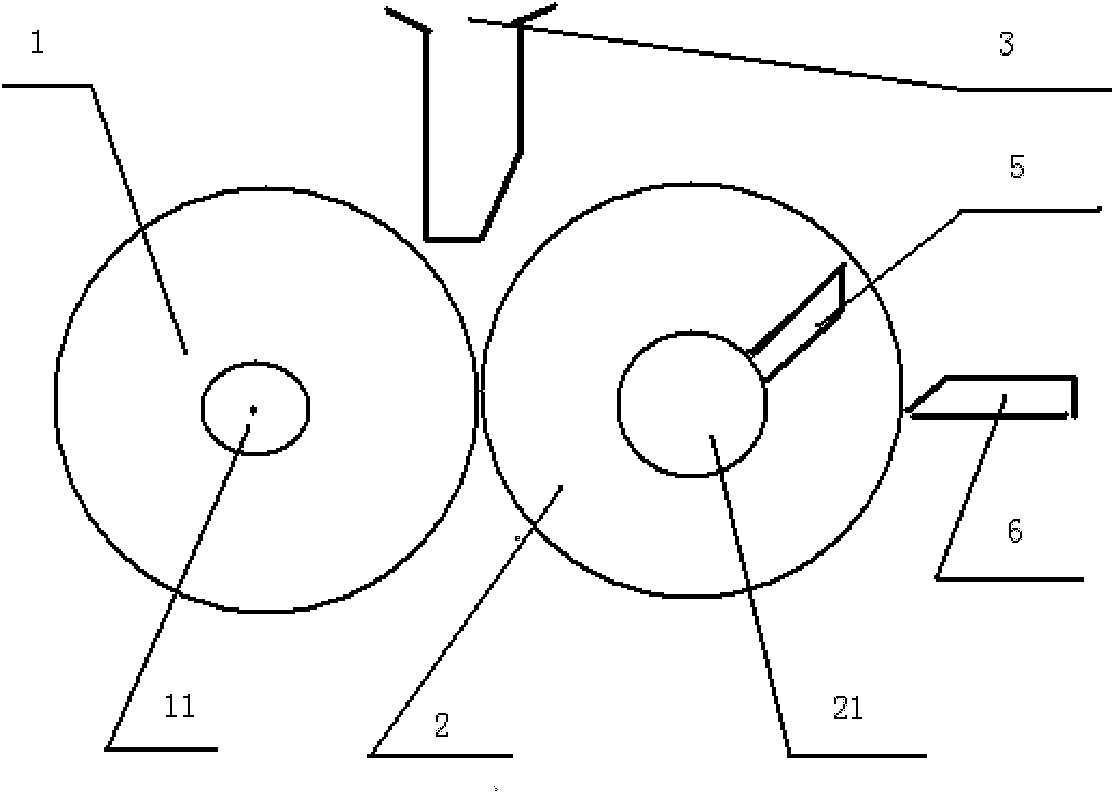

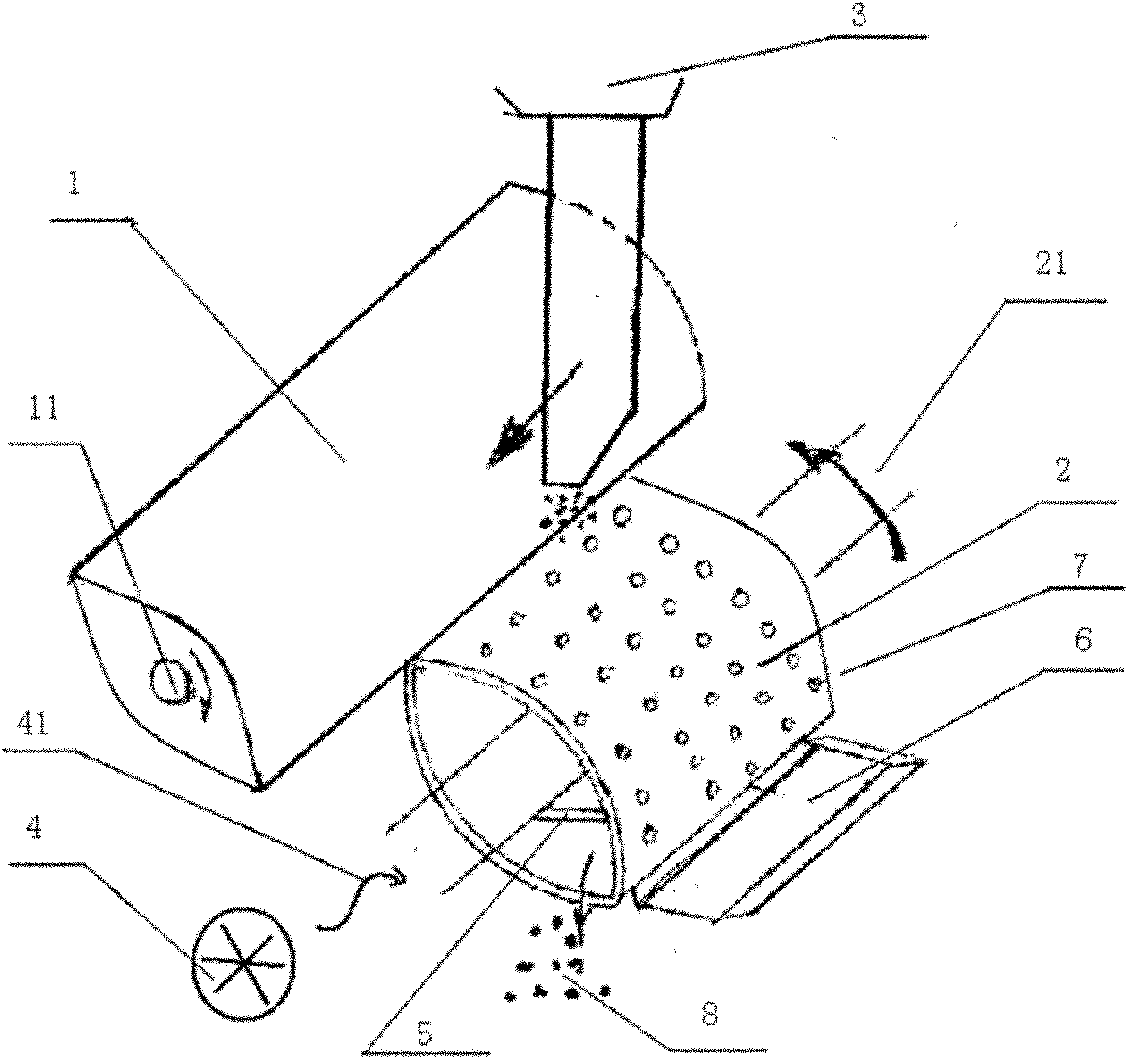

[0014] Such as figure 1 , figure 2 Shown is a schematic structural diagram of a thermosetting plastic granulation device. The device mainly includes feeding port 3, extrusion roller 1, granulation drum 2, cold air blowing device 4, inner wall scraper 5, outer wall scraper 6, etc.

[0015] First, the perforated granulation drum 2 and extrusion roller 1 are circumscribed, and the extrusion roller 1 and granulation drum 2 can rotate in opposite directions; An inner wall scraper 5 is arranged on the inner wall; a cold air blowing device 4 is arranged axially on one side of the granulation drum, and a cold air 41 is blown to the place where the material particles on the inner wall of the granulation drum 2 fall, and the material particles 8 after the granulation are completed are blown out. The pellets are collected after 2 outside the drum.

[0016] Secondly, on the other side where one side of the outer wall of the granulation drum 2 is in contact with the extrusion roller 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com