Diamond chamfering polishing wheel for glass and preparation method thereof

A diamond and polishing wheel technology, applied in the field of polishing wheels, can solve the problems of low comprehensive performance and price ratio, long downtime for wheel replacement, slow chamfering and chamfering line speed, etc., to save downtime for wheel replacement and low motor current , the effect of fast line speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

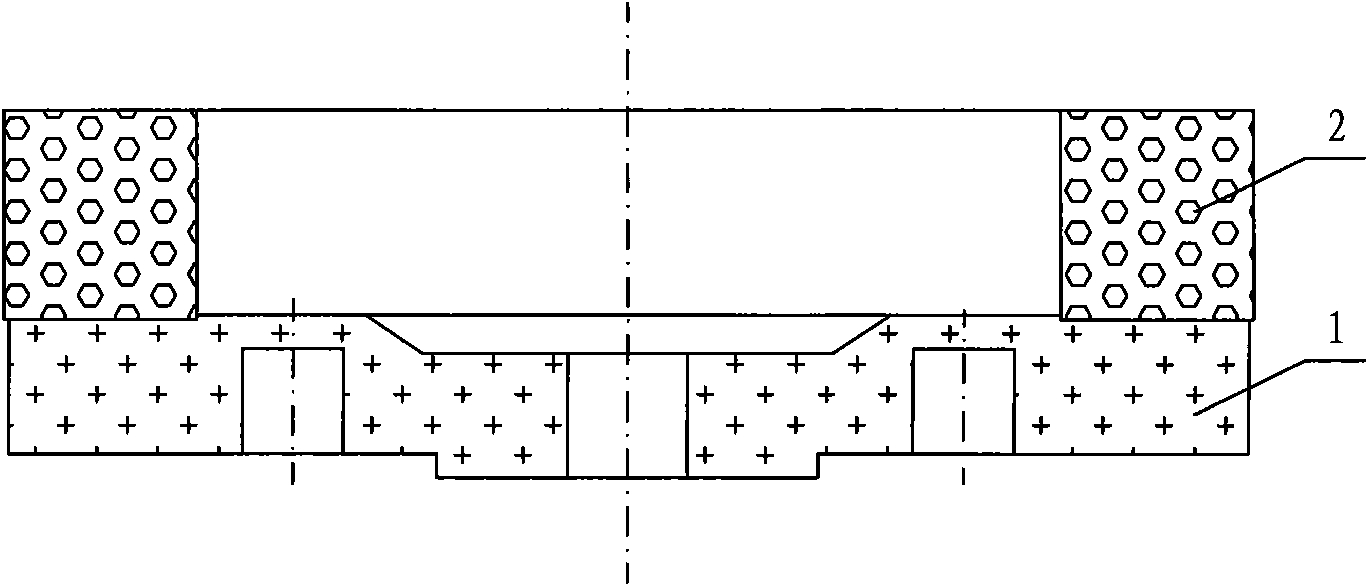

[0017] see figure 1 , the diamond chamfering polishing wheel for glass includes a substrate 1 and an abrasive layer 2, the abrasive layer 2 is prepared from the following raw materials in volume percentage: 10-15% of diamond with a mesh size of 800 or more, 10-15% of silicon carbide with a mesh size of 600 or more %, 55-65% of polyimide resin powder above 500 mesh, 5-10% of copper powder of 325 mesh, 5-10% of silicon carbide above 1000 mesh.

[0018] The abrasive material layer 2 in this embodiment is prepared from the following raw materials in volume percentage: 800 mesh diamond 10%, 600 mesh silicon carbide 15%, 500 mesh or more polyimide resin powder 60%, 325 mesh copper powder 10% , 5% of silicon carbide above 1000 mesh.

[0019] The diamond chamfering polishing wheel for glass includes the following steps during preparation:

[0020] In the first step, the above raw materials are uniformly mixed in proportion to obtain a mixture;

[0021] The second step is to put the...

no. 2 example

[0026] The abrasive material layer 2 in the present embodiment is prepared from the following raw materials in volume percentage: 800 mesh diamond 12%, 600 mesh silicon carbide 13%, polyimide resin powder 55% above 500 mesh, 325 mesh copper powder 10% , 10% of silicon carbide above 1000 mesh.

[0027] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

no. 3 example

[0029] The abrasive layer 2 in this embodiment is prepared from the following raw materials in volume percentage: 800 mesh diamond 15%, 600 mesh silicon carbide 10%, 500 mesh or more polyimide resin powder 65%, 325 mesh copper powder 5% , 5% of silicon carbide above 1000 mesh.

[0030] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com