Method and device for recycling silicon tetrachloride

A technology of silicon tetrachloride and silicon dioxide powder, applied in chemical instruments and methods, silicon halide compounds, halosilanes, etc., can solve the problem of ineffective recycling of reaction heat, large consumption of fresh water, and large amounts of heat energy and other issues, to achieve the effect of small investment, realization of recycling, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

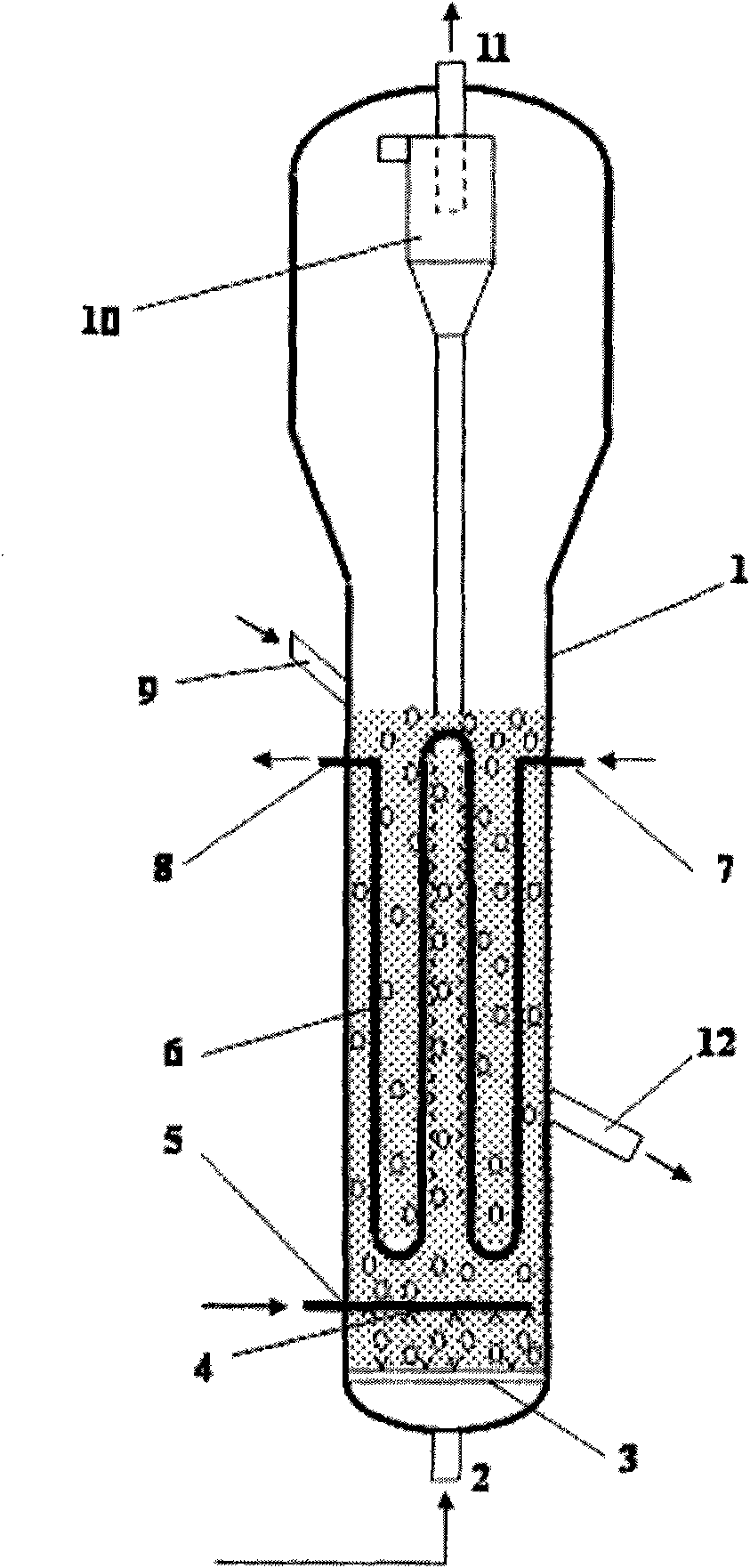

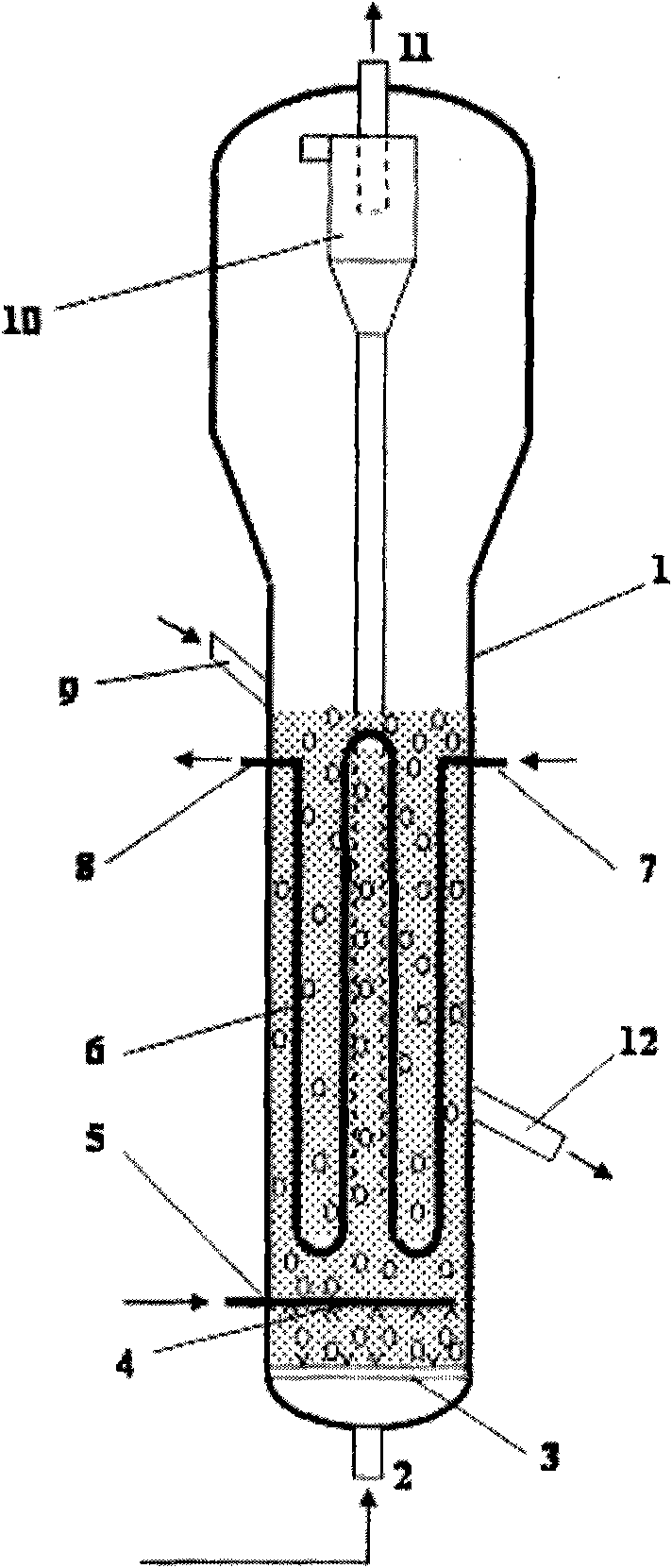

[0065] Select silicon dioxide powder with a particle size range of 80-150 μm, and feed it into the gas-solid fluidized bed reactor through the fluidized medium feed port 9 as the initial fluidized medium. The amount of silicon dioxide powder added is 1 / 2 of the volume of the straight cylinder of the gas-solid fluidized bed reactor.

[0066] The 0.6MPa steam from the boiler is decompressed to 0.1MPa, and the flow is controlled by the steam flow meter to meet the requirements of the feed amount and feed ratio. The water vapor enters the gas-solid fluidized bed reactor evenly distributed through the steam inlet 2 and the steam gas distributor 3 at the bottom of the gas-solid fluidized bed reactor.

[0067] The liquid silicon tetrachloride from the silicon tetrachloride storage tank is pressurized to 0.1MPa through a pump, and the flow is controlled by a flow meter so that the feed ratio of water vapor and silicon tetrachloride is 3.0:1.0, and the gas-solid fluidized bed reaction ...

Embodiment 2

[0072] Select silicon dioxide powder with a particle size of 80-150 μm, and enter the gas-solid fluidized bed reactor through the fluidization medium feed port 9 as the initial fluidization medium. The amount of silicon dioxide powder added is 1 / 2 of the volume of the straight cylinder of the gas-solid fluidized bed reactor.

[0073] The 1.5MPa water vapor by-produced from the tubular heat exchange tube 6 in the gas-solid fluidized bed reactor is decompressed to 0.6MPa, and the flow rate is controlled by a steam flow meter to meet the requirements of the feed amount and feed ratio. The water vapor enters the gas-solid fluidized bed reactor evenly distributed through the steam inlet 2 and the steam gas distributor 3 at the bottom of the gas-solid fluidized bed reactor.

[0074] After the liquid silicon tetrachloride from the silicon tetrachloride storage tank is pressurized to 0.5MPa by a pump, the flow is controlled by a flow meter so that the feed ratio of water vapor and sil...

Embodiment 3

[0079] Select silicon dioxide powder with a particle size of 120-200 μm, and feed it into the gas-solid fluidized bed reactor through the feeding port 6 as the initial fluidized medium. The amount of silicon dioxide powder added is 1 / 2 of the volume of the straight cylinder of the gas-solid fluidized bed reactor.

[0080] The water vapor by-produced from the tubular heat exchange tube 6 in the gas-solid fluidized bed reactor is decompressed to 0.3 MPa, and the flow is controlled by a steam flow meter to meet the requirements of the feed amount and feed ratio. The water vapor enters the gas-solid fluidized bed reactor evenly distributed through the steam inlet 2 and the steam gas distributor 3 at the bottom of the gas-solid fluidized bed reactor.

[0081] The liquid silicon tetrachloride from the silicon tetrachloride storage tank is pressurized to 0.3MPa through a pump, and the flow is controlled by a flow meter so that the feed ratio of water vapor and silicon tetrachloride i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com