Method and equipment for processing deep-fried dough sticks

A processing method and technology of deep-fried dough sticks, which are applied to fried food, dough processing, baking, etc., can solve the problems of gelatinization, large volume, and destruction of gluten network, etc., and achieve the effect of simple structure, small volume, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

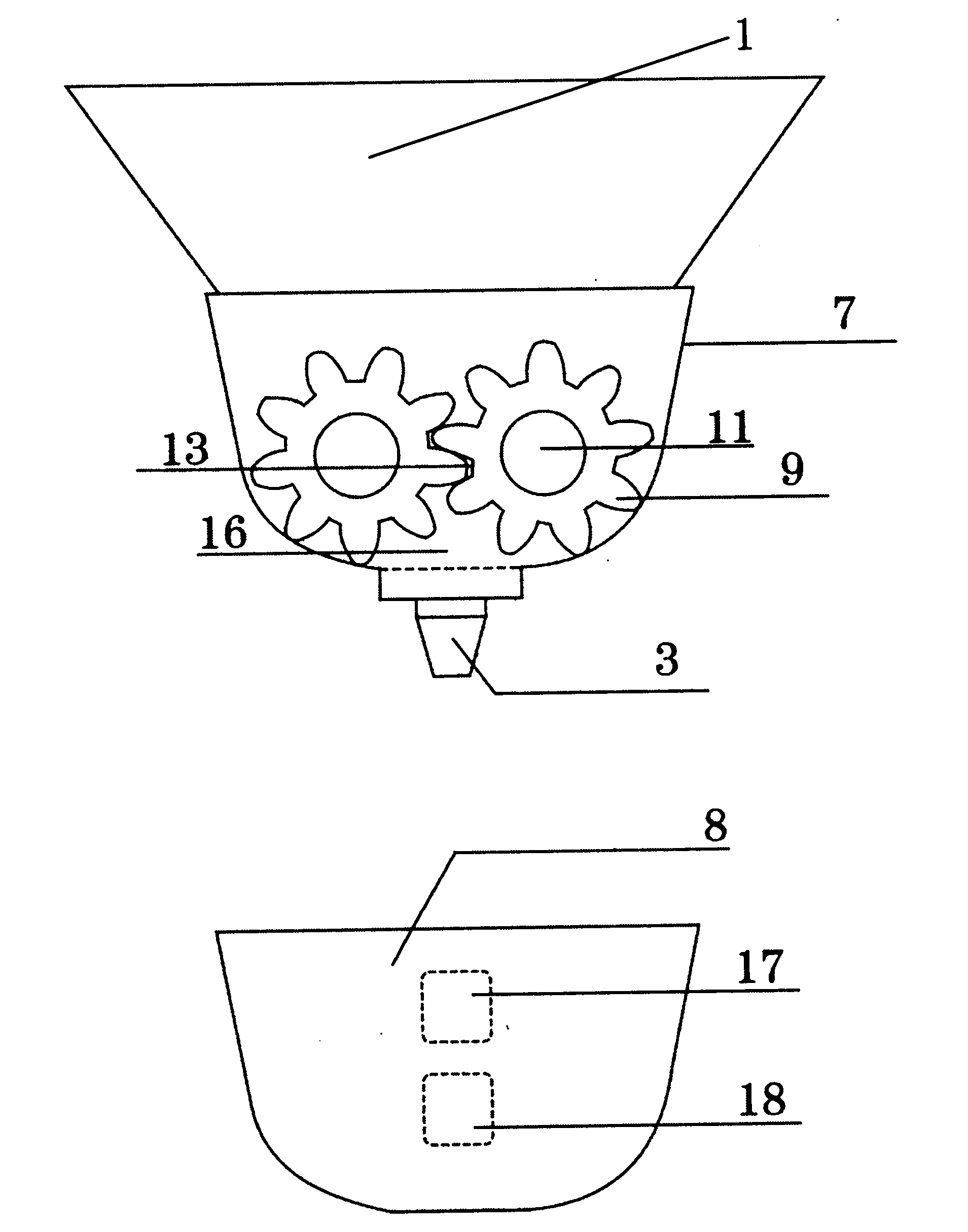

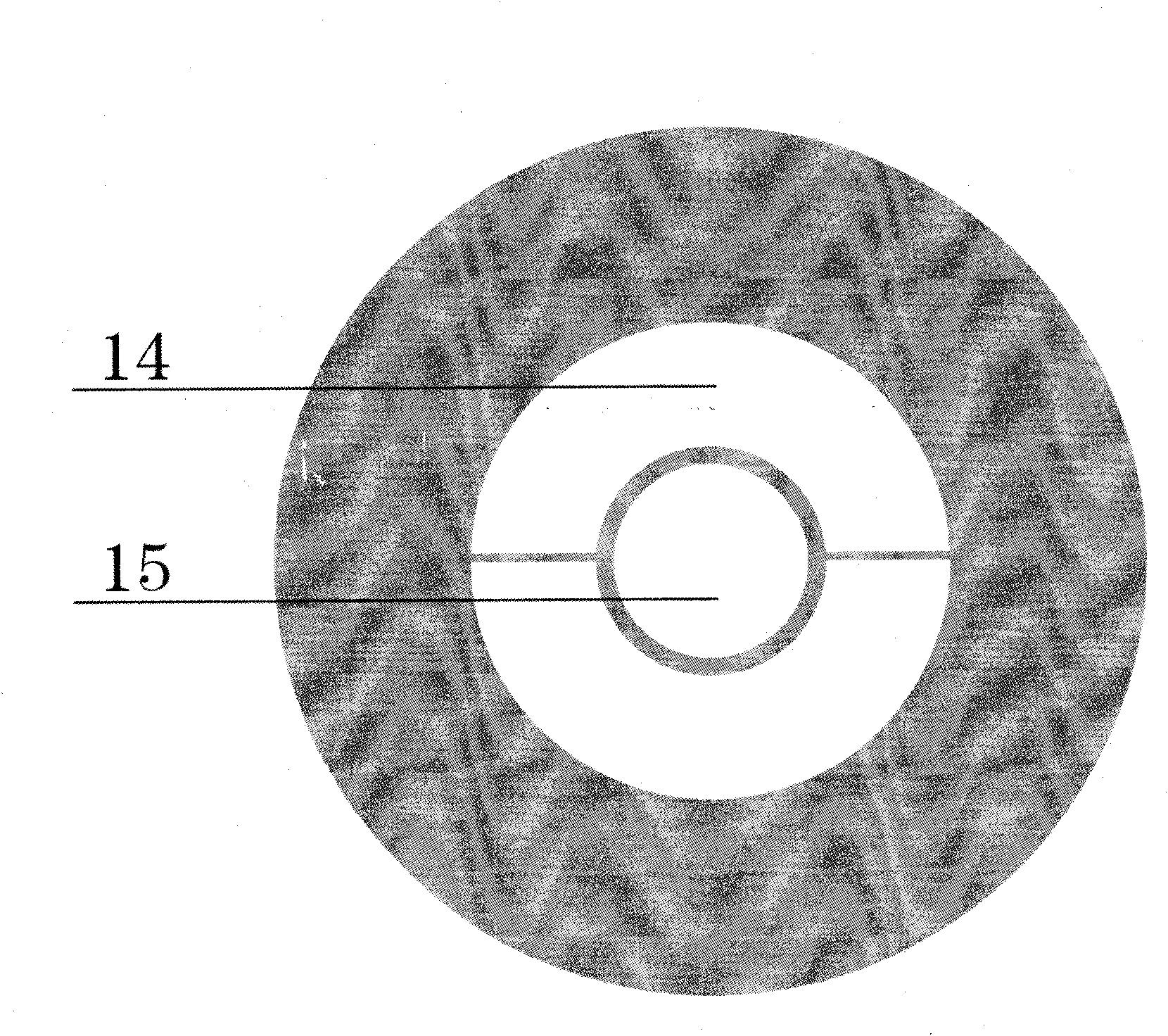

[0077] Example 1 A double disc-shaped spiral fried dough stick

[0078] 3500 grams of high-gluten flour, 1500 grams of low-gluten flour, 600 grams of eggs, 200 grams of skimmed milk powder, 400 grams of shortening, 650 grams of sugar, 60 grams of yeast, 80 grams of leavening agent, 40 grams of salt, 15 grams of improver, 2600 grams of water

[0079] Put the above dry ingredients into the blender and stir evenly, then add egg water shortening and stir until the dough is smooth, the gluten is fully expanded, take out the room temperature and let it rise for 1-3 hours. , the dough is sprayed out from the double-strip nozzle by the dough pump, and directly falls into the oil pan. When the dough floats into the oil pan, hold the bamboo chopsticks and roll the dough sticks into a spiral shape. It depends on the size of the frying container and the oil temperature. Feeding amount, turn off the power, cut off the noodle head and fry the noodle blank at (160-180) ℃ oil temperature. Aft...

example 2

[0081] Example 2 A polygonal disc-shaped spiral fried dough stick

[0082] 2,500 grams of high-gluten flour, 1,000 grams of corn flour, 500 grams of oat flour, 500 grams of millet flour, 500 grams of whole potato flour, 3,000 grams of milk, 2,800 grams of eggs, 1,200 grams of butter, 300 grams of sugar, 2,500 grams of water, 30 grams of salt, 15 grams of improver, 8 grams of vanilla powder

[0083] First put the milk, butter, water and salt into the pot to boil, then pour in the flour and stir continuously with a wooden stick to make the flour heat and gelatinize to form a dough. When the temperature of the dough drops to the point where it is not hot to the touch, put it into the mixer, add eggs while stirring, and finally add the sugar improver vanilla Mix the flour into a soft and hard dough, divide the dough into appropriate sizes and put them in the hopper of the fried dough stick equipment, turn on the power, the dough will be sprayed out from the multi-edged nozzle by th...

example 3

[0085] Example 3 A long fried dough stick

[0086] 5000 grams of all-purpose flour, 1200 grams of sugar, 800 grams of eggs, 300 grams of cream, 200 grams of milk powder, 60 grams of yeast, 15 grams of improver, 15 grams of salt, 1800 grams of water

[0087] Pour the dry ingredients into the blender and mix well, add the remaining ingredients and water and stir to form a smooth dough, take it out of the room temperature and leave it for 30 minutes, divide it into appropriate sizes and put it into the hopper of the fried dough stick equipment, turn on the power, and the dough will be sprayed from the round bar nozzle through the dough pump Take it out, cut it into fried dough sticks according to the length of 40 cm (or process the dough into fried dough sticks by hand), put it in a steaming tray and put it in a steaming room (temperature 32-36 degrees Celsius and humidity 80%) for 30-60 minutes, take it out Steam in a steam box, put the steamed fried dough sticks into an oil pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com