Three-dimensional nanoporous metal-oxide electrode material of lithium ion battery and preparation method thereof

一种锂离子电池、三维纳米的技术,应用在电池电极、非水电解质蓄电池电极、电极制造等方向,能够解决难以满足电池高容量化的要求、体积比容量没有优势、碳材料的充放电比容量低等问题,达到适于大规模推广应用、提高比表面积和离子导电性能、操作简单方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

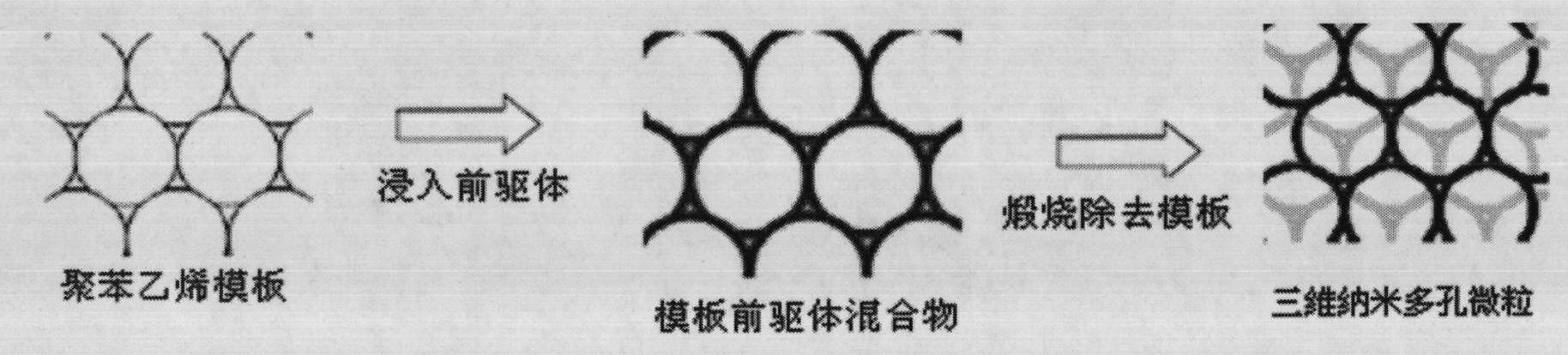

[0031] Three-dimensional nanoporous metal oxide electrode material α-Fe for lithium-ion batteries 2 o 3 Preparation and performance testing of

[0032] (1) Preparation of polystyrene colloidal microsphere template

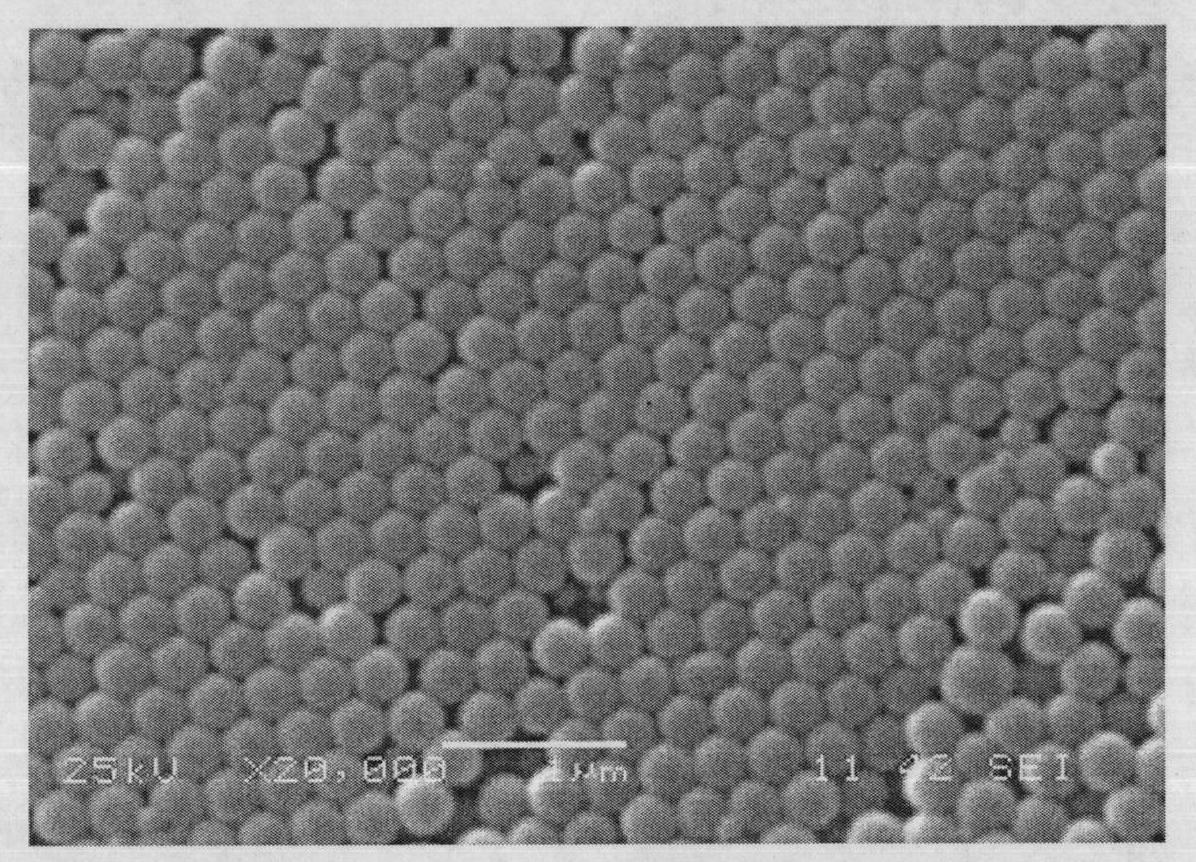

[0033] Adopt the method for emulsion polymerization to prepare 275 ± 10nm polystyrene microsphere emulsion, arrange microsphere into polystyrene colloidal microsphere template (such as figure 2 As shown), the scanning electron microscope shows that the polystyrene colloidal microsphere template is multi-layered, orderly, and regularly arranged in a large area, with fewer defects and a strong sense of hierarchy.

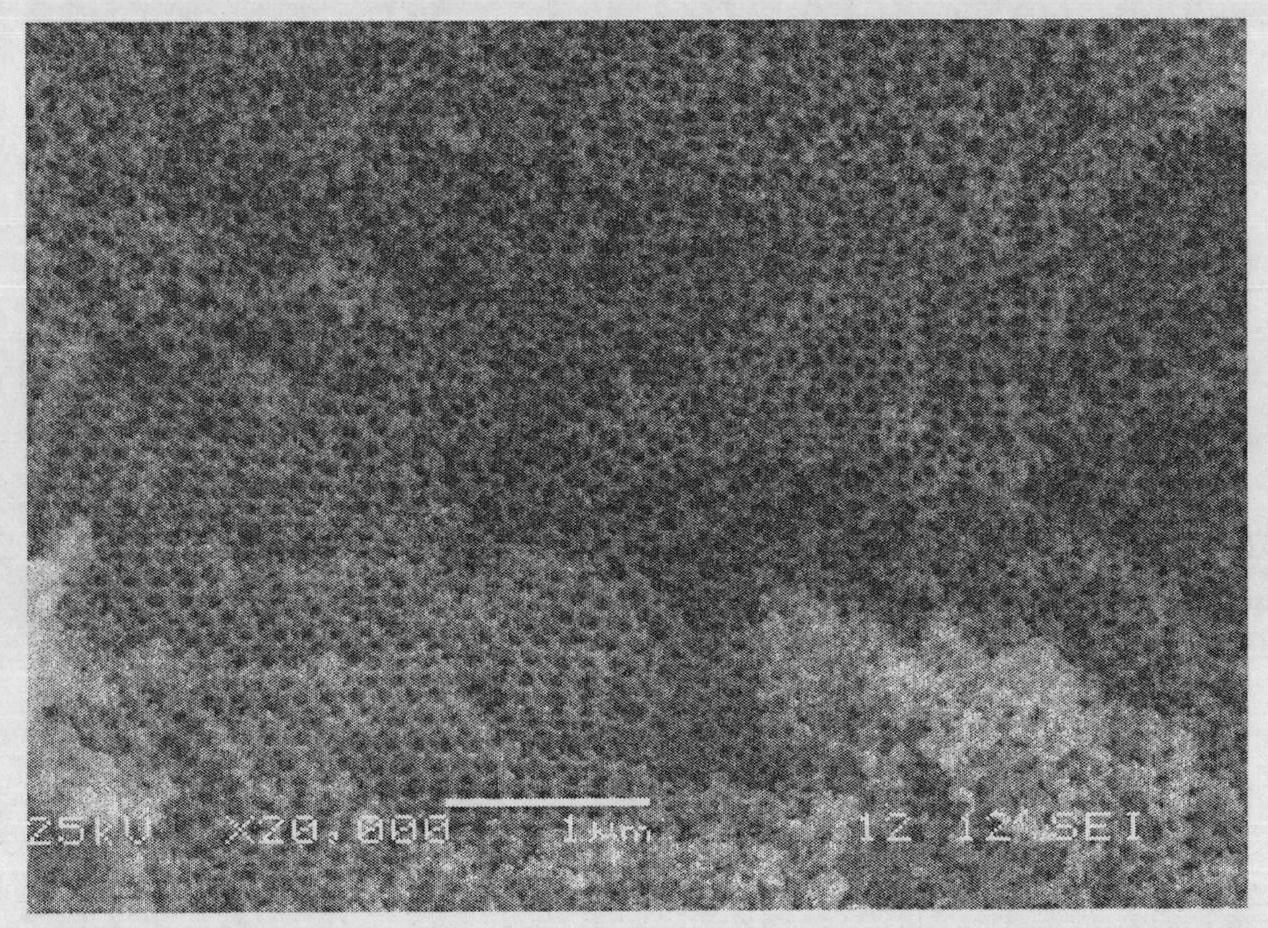

[0034] (2) Three-dimensional nanoporous metal oxide electrode material α-Fe for lithium-ion batteries 2 o 3 the acquisition

[0035] with Fe 3+ The mixed solution of ethylene glycol / methanol is the precursor solution, and the dried polystyrene colloidal microsphere template is soaked in the precursor solution for 5 hours, and the precursor template ...

Embodiment 2

[0040] Three-dimensional nanoporous metal oxide electrode material CoFe for lithium-ion batteries 2 o 4 Preparation and performance testing of

[0041] (1) Preparation of polystyrene colloidal microsphere template

[0042] Adopt the method for emulsion polymerization to prepare 275 ± 10nm polystyrene microsphere emulsion, microsphere is arranged into polystyrene colloidal microsphere template (such as Figure 4 As shown), the scanning electron microscope shows that the polystyrene colloidal microsphere template is multi-layered, orderly, and regularly arranged in a large area, with fewer defects and a strong sense of hierarchy.

[0043] (2) CoFe, a three-dimensional nanoporous metal oxide electrode material for lithium-ion batteries 2 o 4 the acquisition

[0044] Prepare the total metal ion concentration to be 1.5mol L-1 (molar ratio, Fe 3+ :Co 2+ =2:1) ethylene glycol / methanol (mixed solution as the precursor solution. Soak the dried PS colloidal crystal template parti...

Embodiment 3

[0049] Three-dimensional nanoporous metal oxide electrode material SnO for lithium-ion batteries 2 · Preparation and performance testing

[0050] (1) Preparation of polystyrene colloidal microsphere template

[0051] Adopt the method for emulsion polymerization to prepare 275 ± 10nm polystyrene microsphere emulsion, microsphere is arranged into polystyrene colloidal microsphere template (such as Figure 4 As shown), the scanning electron microscope shows that the polystyrene colloidal microsphere template is multi-layered, orderly, and regularly arranged in a large area, with fewer defects and a strong sense of hierarchy.

[0052] (2) Three-dimensional nanoporous metal oxide electrode material SnO for lithium-ion batteries 2 the acquisition

[0053] Prepare SnCl with a total metal ion concentration of 0.5mol / L 2 2H 2 The ethanol solution of O is the precursor solution. Soak the dried PS colloidal template particles in the precursor solution for 10 h, and then vacuum filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap