Improved ball valve

An improved ball valve technology, applied in the valve details, valve device, valve shell structure, etc., can solve the problems of smooth connection with dead angle, poor sealing performance, heavy valve weight, etc., to achieve smooth connection without dead angle, save Effects of reduced installation space and external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

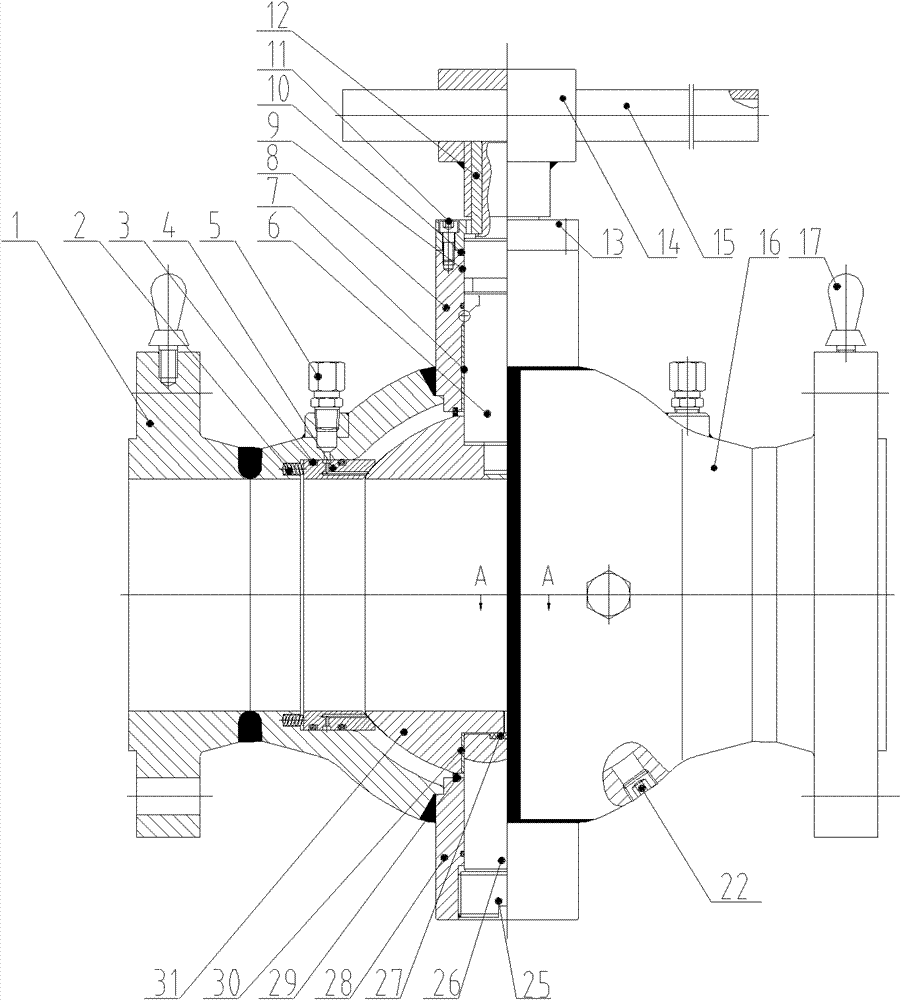

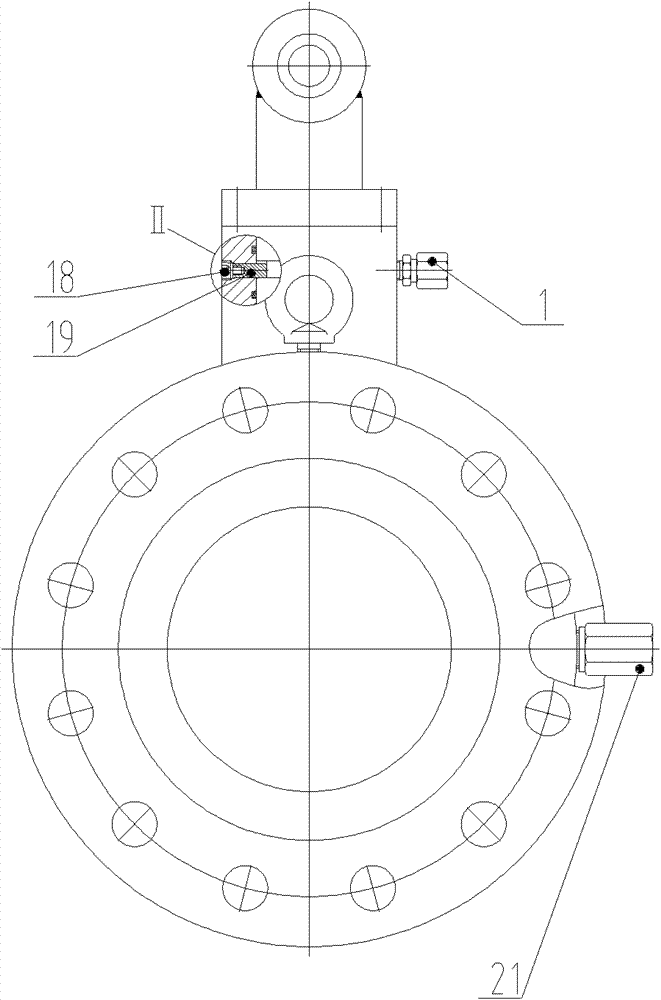

[0018] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0019] Valve body: The valve body is a welded forged steel structure with left and right valve bodies. The welding of the valve body is carried out in strict accordance with the welding process. It is welded by gas shielded welding or automatic submerged arc welding machine. All welds have passed 100% UT inspection.

[0020] Stuffing box: The stuffing box is welded on the valve body, and the leakage point is eliminated. At the same time, the device for preventing the valve stem from blowing out is installed on the gland, which is convenient for the disassembly and installation of the valve stem parts and can be replaced online (when the valve is not affected) Stem graphite seal.

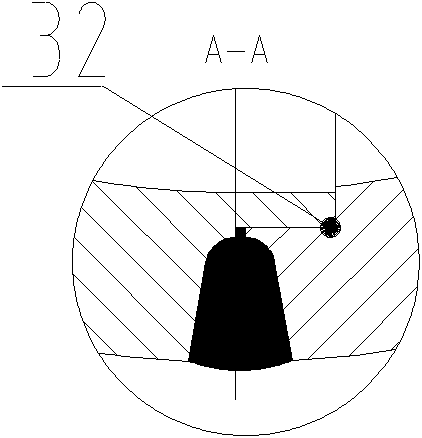

[0021] Ball: Forged carbon steel or stainless steel ball, fixed construction. The material is A105, A350LF2, A182F304, the surface is supersonic sprayed tungsten carbide alloy, the ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com