Method for integrally dismounting and installing furnace top system of blast furnace

A technology of overall installation and blast furnace, applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems of large cross-operation interaction, difficult logistics organization, and rising profits, so as to reduce the workload of online construction and shorten the on-line The effect of reducing the construction period and working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The roof of a blast furnace needs to be dismantled for maintenance of the blast furnace. The bottom of the roof system is 46m above the ground, and the overall dismantling method of the blast furnace roof system is now used.

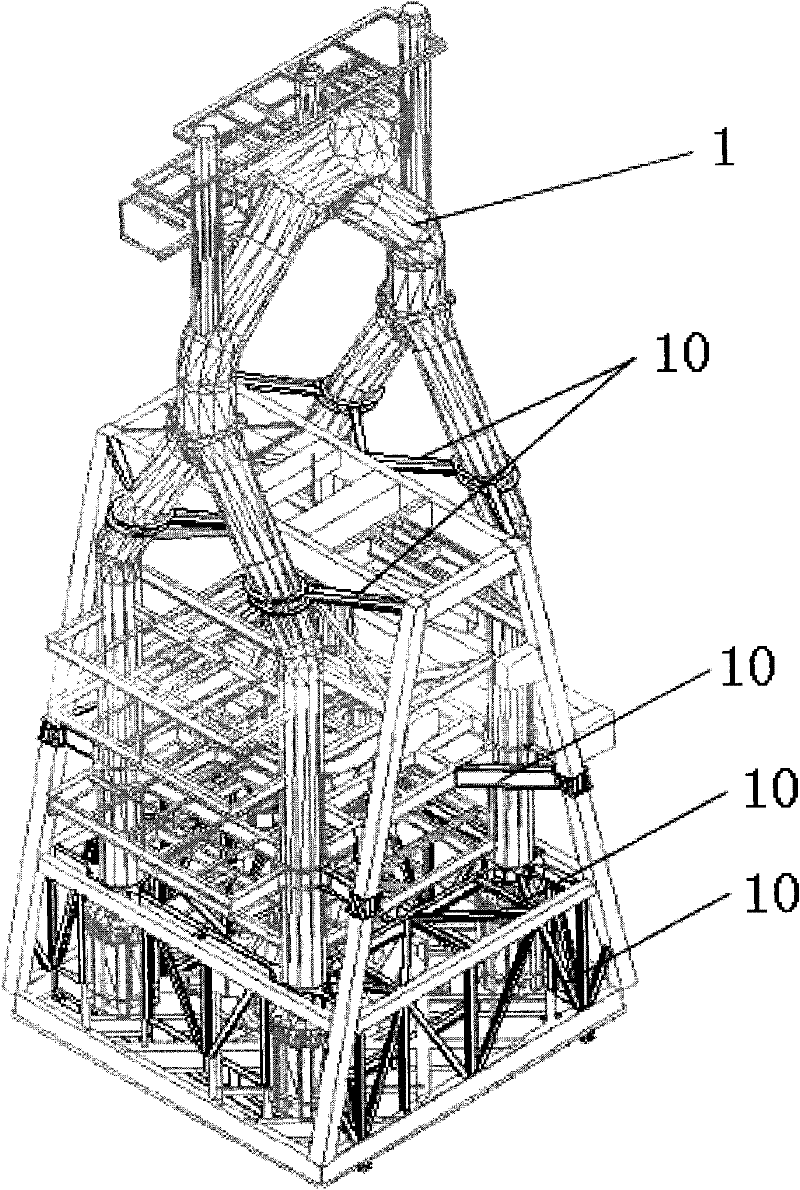

[0037] The blast furnace roof system 1 includes the old seven-story platform above 46m and above structures and equipment, furnace roof frame, gas riser pipe, auxiliary platform, furnace roof equipment, etc., weighing more than 2,600 tons, and is connected and reinforced with connecting facilities 10. into one, as figure 1 shown.

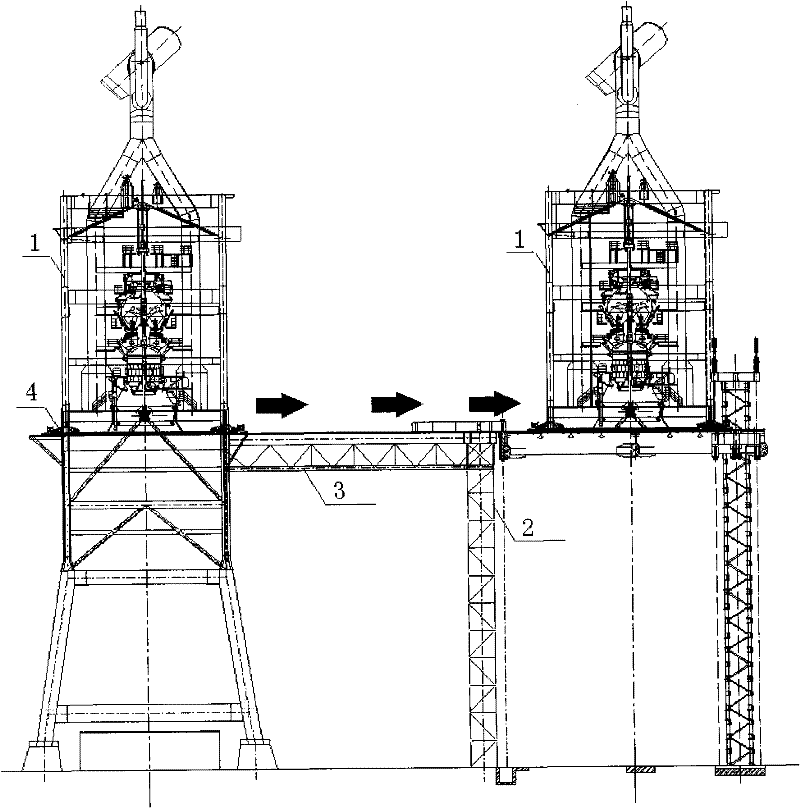

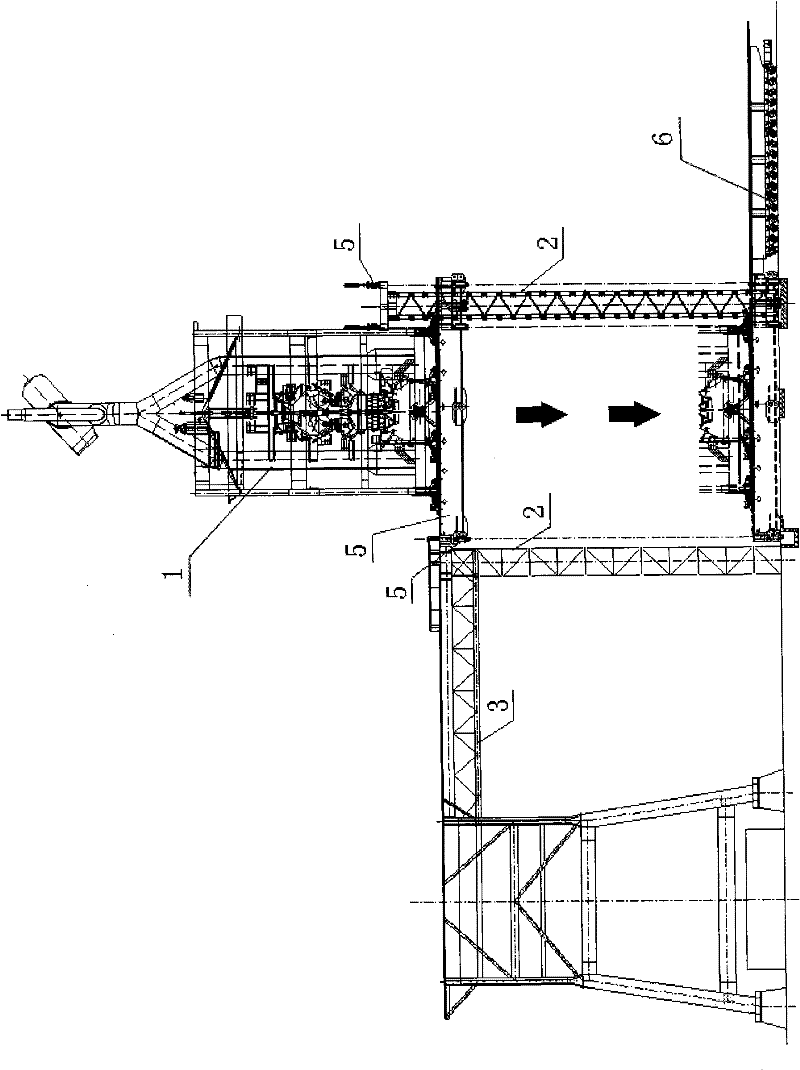

[0038] Such as figure 2 As shown, a supporting frame 2 is erected on the ground on one side of the blast furnace, and a sliding truss 3 is fixed on the supporting frame 2. The height of the sliding truss 3 is the height of the blast furnace roof system 1. Move the car 4, install a hoist 5 on the top of the support frame 2, the hoist 5 adopts a hydraulic lift, place a transport car 6 on the ground next to the hoist 5,...

Embodiment 2

[0044] Now it is necessary to install the blast furnace roof on a blast furnace, the bottom of the furnace roof system is 46m above the ground, and the overall installation method of the blast furnace roof system is now adopted.

[0045] Blast furnace roof system 1 includes structures and equipment above 46m, furnace roof frame, gas riser pipe and ball joints, furnace roof equipment above the material tank, electrical instruments, furnace top small piping, hydraulic piping, etc., weighing more than 2,400 tons. Such as Figure 7 As shown, it is first assembled into a whole off-line on the ground, and then connected and reinforced with the connection facility 10 to form a whole.

[0046] Such as Figure 8 As shown, the blast furnace roof system 1 that has been integrally connected and reinforced is placed on the sliding assembly device 42, and the blast furnace roof system 1 is moved to the transport vehicle 6. For safety and reliability during transportation, a slide is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com