Movable steel gate plate and movable wall for dyke

A technology of movable walls and steel gates, applied in the direction of coastline protection, etc., can solve the problems of huge cost and heightening of dikes, and achieve the effects of reducing flood fighting costs, saving maintenance costs, and facilitating disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

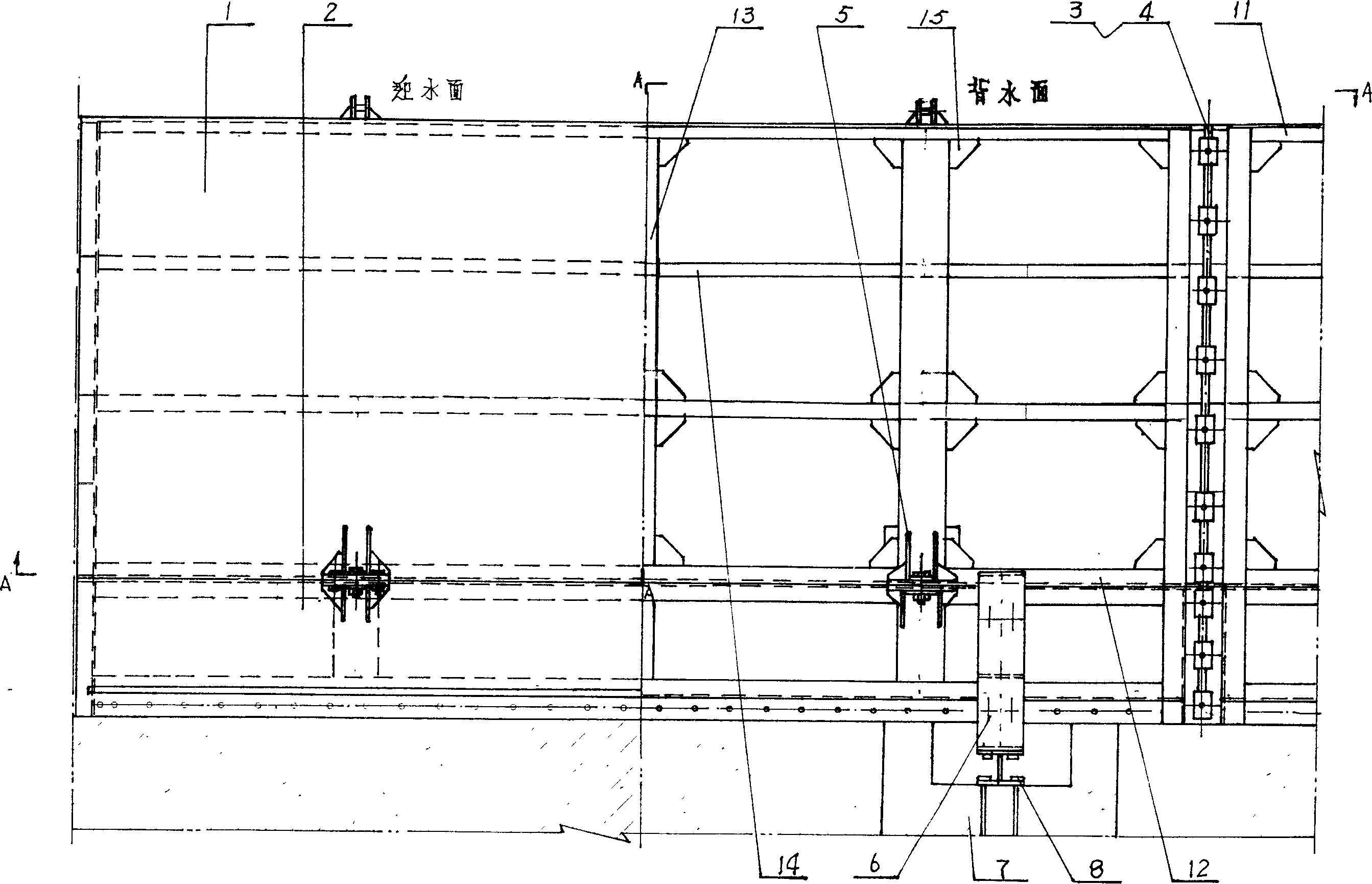

[0031] Take the Harbin section of the Songhua River as an example using the embankment movable steel gate movable wall of the present invention, because this section has a 0.6-meter-high concrete cofferdam, so the described movable wall includes a 2.0-meter-high concrete cofferdam that is installed on the cofferdam. A group of connected individual rams 1 called the "General Section", and a 0.6-meter-high individual ram 2 (filled in the pedestrian passageway from the river embankment to the ship station and the river) and 2.0 meters high. In this way, if the height of the dam can be blocked by 0.6 meters according to the amount of flood, only 0.6 meters of gates should be installed at the gates that people usually pass through. A single ram is enough. If the water level needs to be increased by more than 0.6 meters, a 2.0-meter single ram 1 can be installed on the 0.6-meter single ram 2 to keep the same height as the general section, or other can be selected according to needs. ...

Embodiment 2

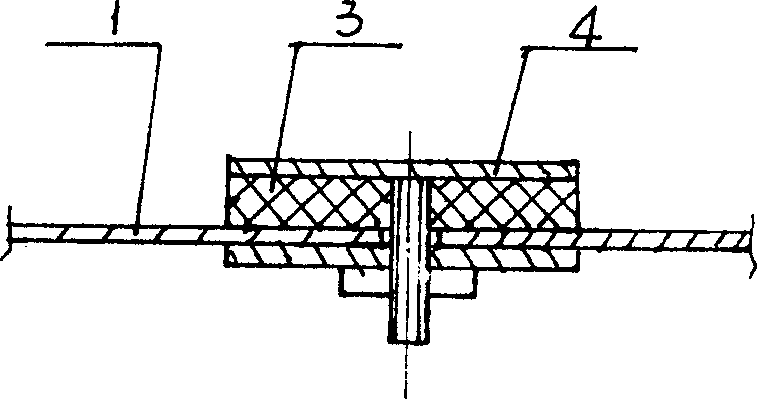

[0036] The movable steel ram movable wall of the embankment adopts a steel structure design, wherein the upper and lower sides of the single ram 1 or the single ram are fixed with an upper beam 11 and a lower beam made of section steel such as channel steel or square steel. 12. A longitudinal beam 13 is installed between the upper beam 11 and the lower beam 12. If a scheme with a height of more than 1.5 meters or a length of more than 1.5 meters is adopted, the space between the upper beam 11 and the lower beam 12 and the longitudinal beam Rigid reinforcing ribs 14 distributed vertically and horizontally should be housed, and the setting of reinforcing ribs is preferably no more than 1.5 meters in longitudinal and transverse distances, and angled reinforcing plates 15 can be installed between the reinforcing ribs.

[0037] If the height is less than 1 meter, no transverse reinforcing ribs can be added, and longitudinal ribs are arranged according to the length of the single gat...

Embodiment 3

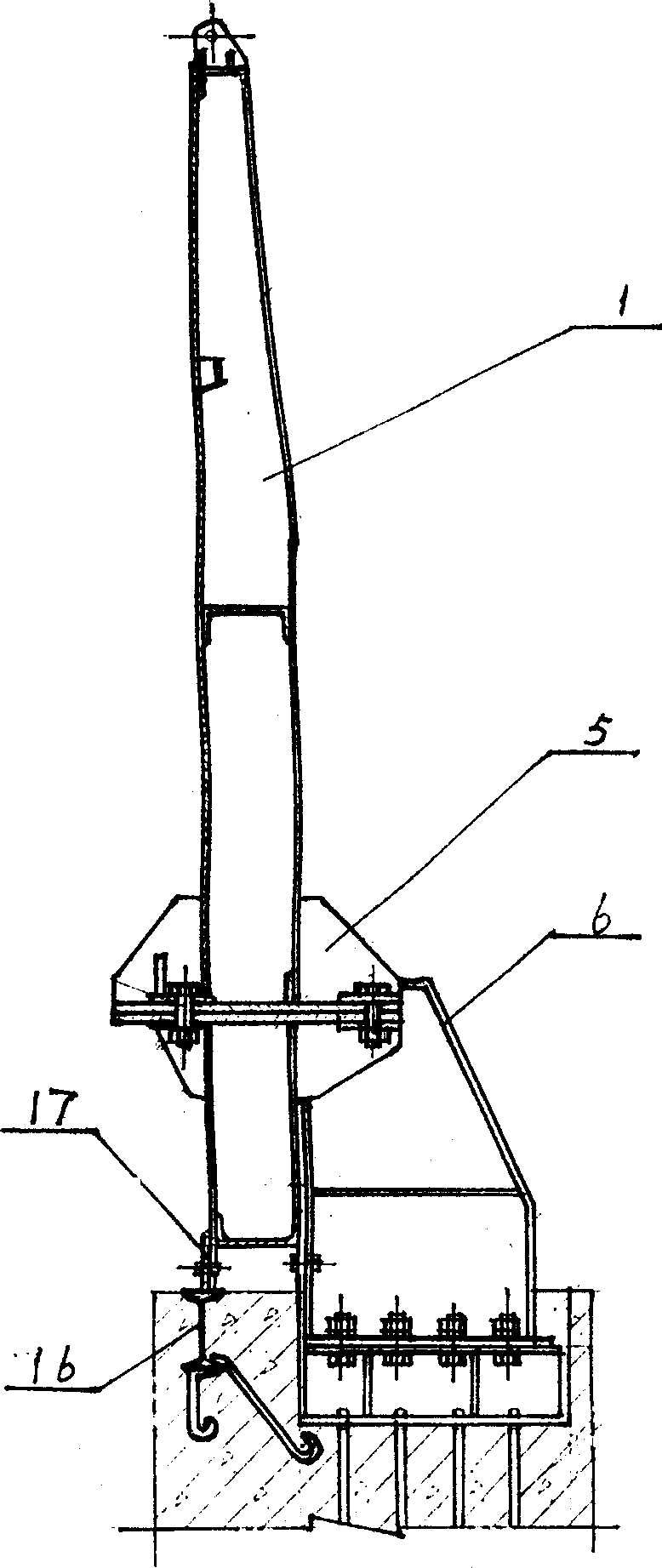

[0040] In the movable steel ram movable wall of the embankment, the bottom surface of the single ram 1 or the single ram 2 can be fixed by bolts 16 pre-embedded on the cofferdam, so that the force on the single ram is within Decomposition occurs during transmission to the foundation, reducing the overturning moment and horizontal thrust of the single ram to the support. A sealing strip 17 is installed between the bottom surface of the ram and the cofferdam to prevent leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com