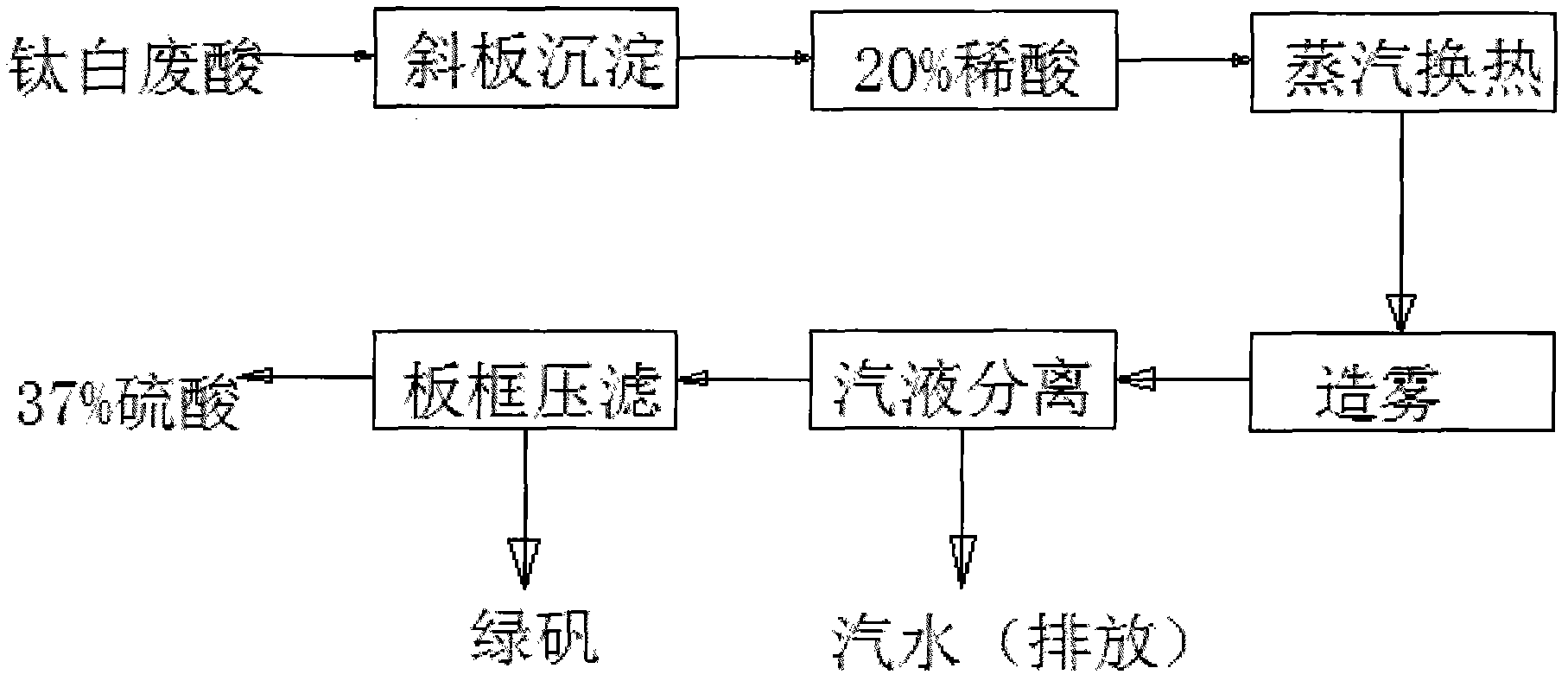

Waste acid concentration multistage treatment method

A treatment method, acid concentration technology, applied in water/sewage multi-stage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve problems affecting equipment maturity, lower thermal efficiency, increase cost, etc., to achieve Save cooling water, save material, save steam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in combination with specific embodiments.

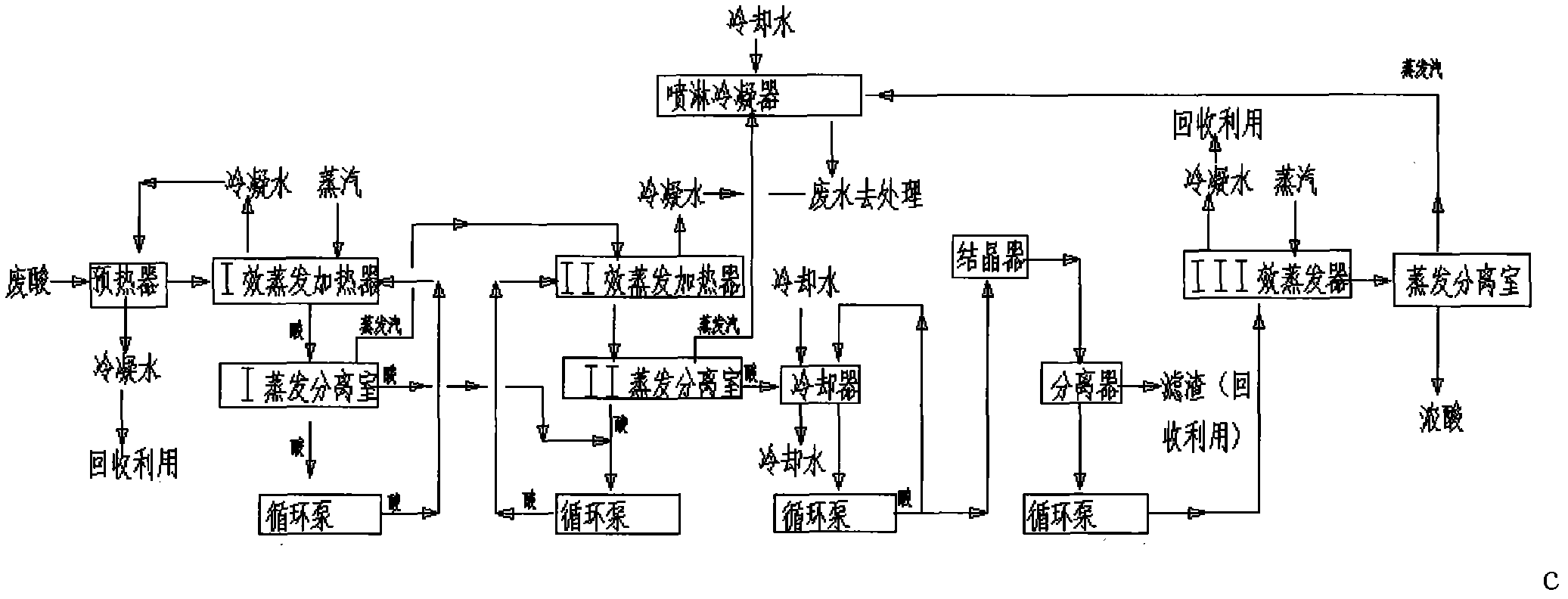

[0030] figure 2 It is a schematic diagram of the connection relationship of the waste acid concentration multi-stage treatment device. refer to figure 2 As shown, the waste acid concentration multi-stage treatment device includes preheater, I-effect evaporating heater, I-effect evaporating separator, II-effect evaporating heater, II-effect evaporating separator, cooler, crystallizer, separator, III Efficient evaporation heaters, evaporation separators, and various components are connected in series in sequence with pipes.

[0031] And between the I-effect evaporative heater and the I-effect evaporative separator, and between the II-effect evaporative heater and the II-effect evaporative separator, a circulation pump is set to realize the circulation operation of the material; the cooler is connected with a circulation pump to make the II-effect The acid outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com