Functional graphene oxide for adjusting and controlling dispersibility of solvent by using organic chain segment as well as preparation method thereof

A solvent-dispersed and functionalized technology, applied in the field of surface modification and modification of graphene oxide, can solve problems such as loss of dispersing ability, and achieve the effects of saving energy, speeding up the reaction, good application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

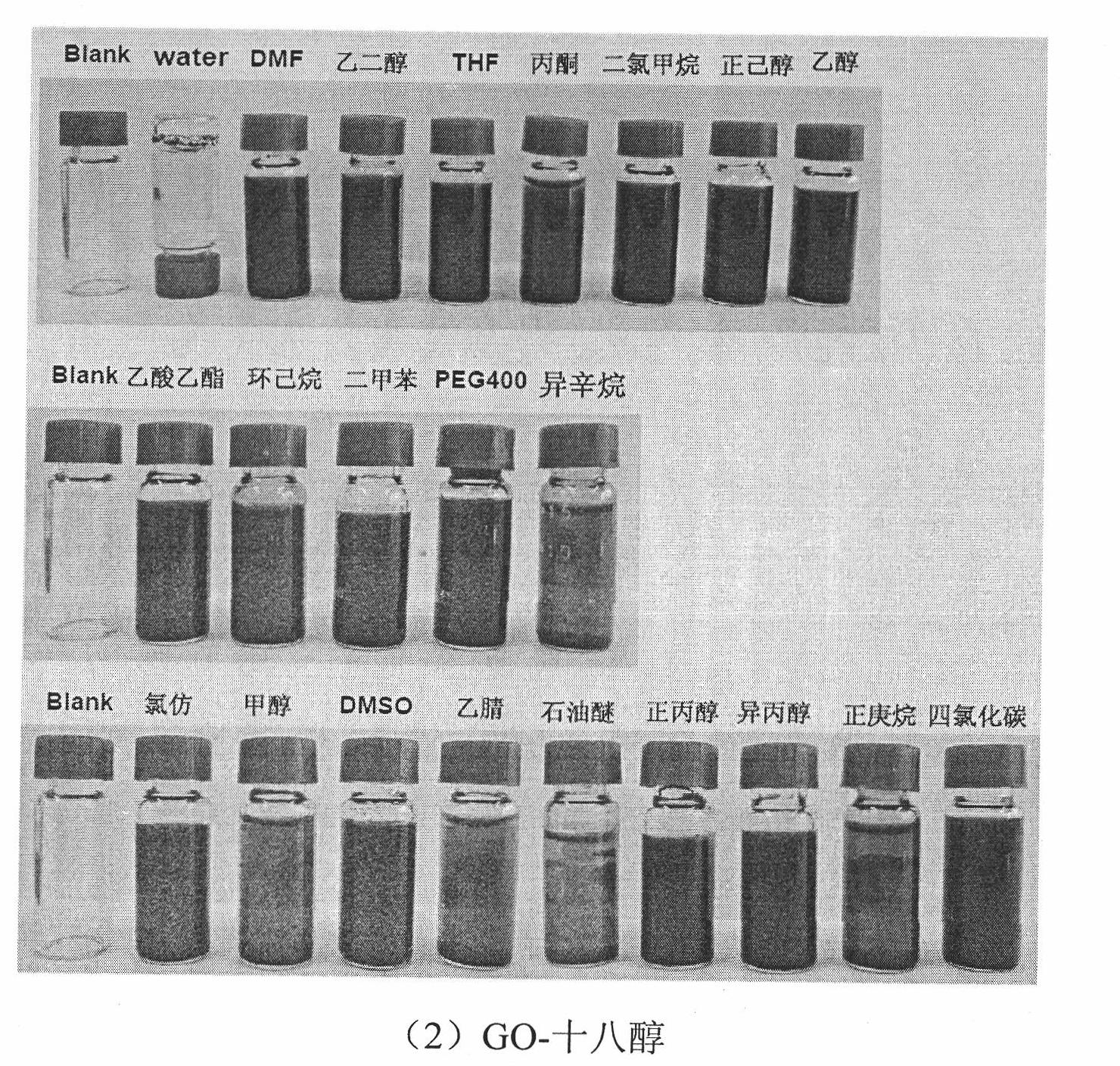

[0030] combine figure 2 , the present invention utilizes organic segment to regulate the preparation method of the functionalized graphene oxide of solvent dispersion performance, and the steps are as follows:

[0031] In the first step, the graphite oxide prepared by the Hummers method is dispersed in N,N-dimethylformamide (DMF) to form a uniform dispersion;

[0032] In the second step, the thionyl chloride reagent is added to the product obtained in the first step, and the reflux reaction is synthesized to synthesize the graphite oxide intermediate product activated by acid chloride;

[0033] The 3rd step, the mixed solution of the second step of underpressure distillation, removes unnecessary thionyl chloride;

[0034] The fourth step is to add pyridine to the product of the third step. After grafting organic molecules or polymer molecules, heat and stir the mixture, and add a certain amount of pyridine as a catalyst and acid-binding agent to speed up the reaction. The am...

Embodiment 1

[0038] Embodiment 1: The present invention synthesizes the graphene oxide of organic molecule modification, comprises the following steps:

[0039] The first step is the preparation of graphite oxide.

[0040] Pre-oxidation of graphite:

[0041] Heat 30mL of concentrated sulfuric acid to 80°C, add 10g K2S2O8 and 10g P2O5, and then slowly add 20g graphite. A dark blue mixture was obtained. After the addition was complete, the mixture was allowed to cool naturally to room temperature over 6 hours. After carefully adding distilled water, filter and wash with plenty of water. until the pH of the filtrate is neutral. The filter cake was dried overnight at room temperature.

[0042] Graphite oxide prepared by Hummer's method:

[0043] Cool 460mL of concentrated sulfuric acid to about 0°C, then add 20g of pre-oxidized graphite into it, and then slowly add 60g of potassium permanganate so that the temperature of the system does not exceed 20°C, after the addition is completed, r...

Embodiment 2

[0049] Embodiment 2: The present invention synthesizes the graphene oxide of organic molecule modification, comprises the following steps:

[0050] The first step is the same as step 1 in Example 1;

[0051] In the second step, 200 mg of graphite oxide was added to 7.5 mL of DMF solvent, and ultrasonically dispersed until a uniform mixture was obtained;

[0052] In the third step, add 40 mL of thionyl chloride to the mixture in the first step, and reflux at 80° C. for 24 hours;

[0053] The 4th step, the mixed solution of the 3rd step of underpressure distillation, removes unnecessary thionyl chloride;

[0054] In the fifth step, 15 mL of pyridine was added to the product of the fourth step, and after adding 2 g of PEG400, reflux reaction at 120 ° C for 3 days;

[0055] In the sixth step, the mixture obtained in the fifth step was suction-filtered, washed with ethanol, and dried overnight at 60° C. in vacuum to obtain PEG400-modified graphene oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com