Method for transporting aluminum milling scraps to complexification workshop through pipelines

A technology for workshops and milling chips, which is applied in the field of conveying aluminum milling chips to compound workshops. It can solve the problems of large forklift or car transportation, limited number of material boxes, and aluminum milling chips that cannot be smelted again, so as to improve production efficiency. The effect of saving repeated transportation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

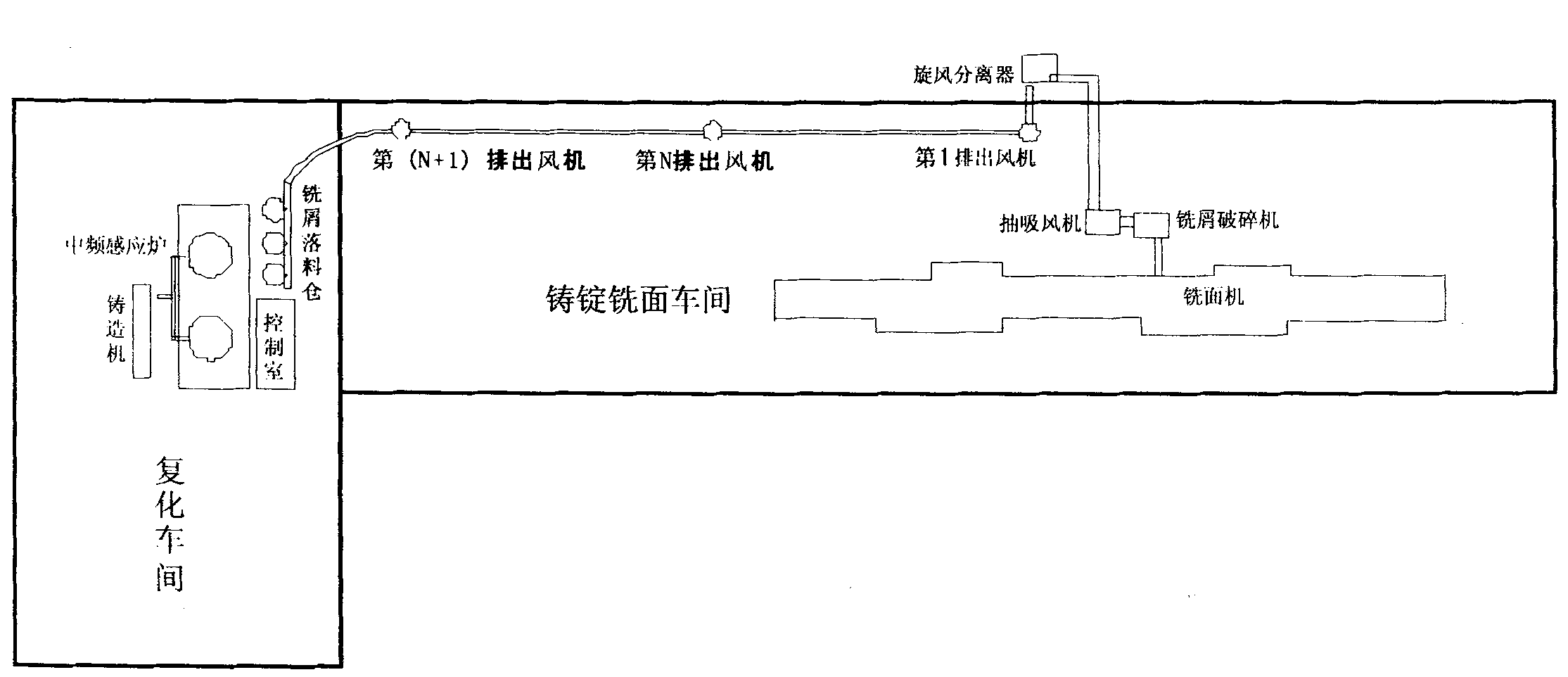

[0017] Combine figure 1 The equipment involved in the present invention includes the milling machine, suction fan, milling chip crusher and cyclone separator in the ingot milling workshop, as well as the milling chip blanking bin in the compounding workshop, and the pipeline is installed in the ingot milling workshop And the roof of the compounding workshop and the two ends of the pipe are respectively introduced into the ingot milling workshop and the compounding workshop.

[0018] On the basis of the above, the pipes introduced into the ingot milling workshop are connected to the milling chip crusher after the suction fan is connected. The cyclone separator is installed on the roof of the ingot milling workshop, and the section connected from the suction fan The pipe is connected with the inlet end of the cyclone separator, and the outlet end of the cyclone separator is connected with the first exhaust fan after connecting a short section of pipe. The first exhaust fan is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com