Photovoltaic modules and production process

A technology of photoelectric components and batteries, applied in the fields of electrical components, photovoltaic power generation, chemical instruments and methods, etc., can solve the problems of preparing expensive components and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

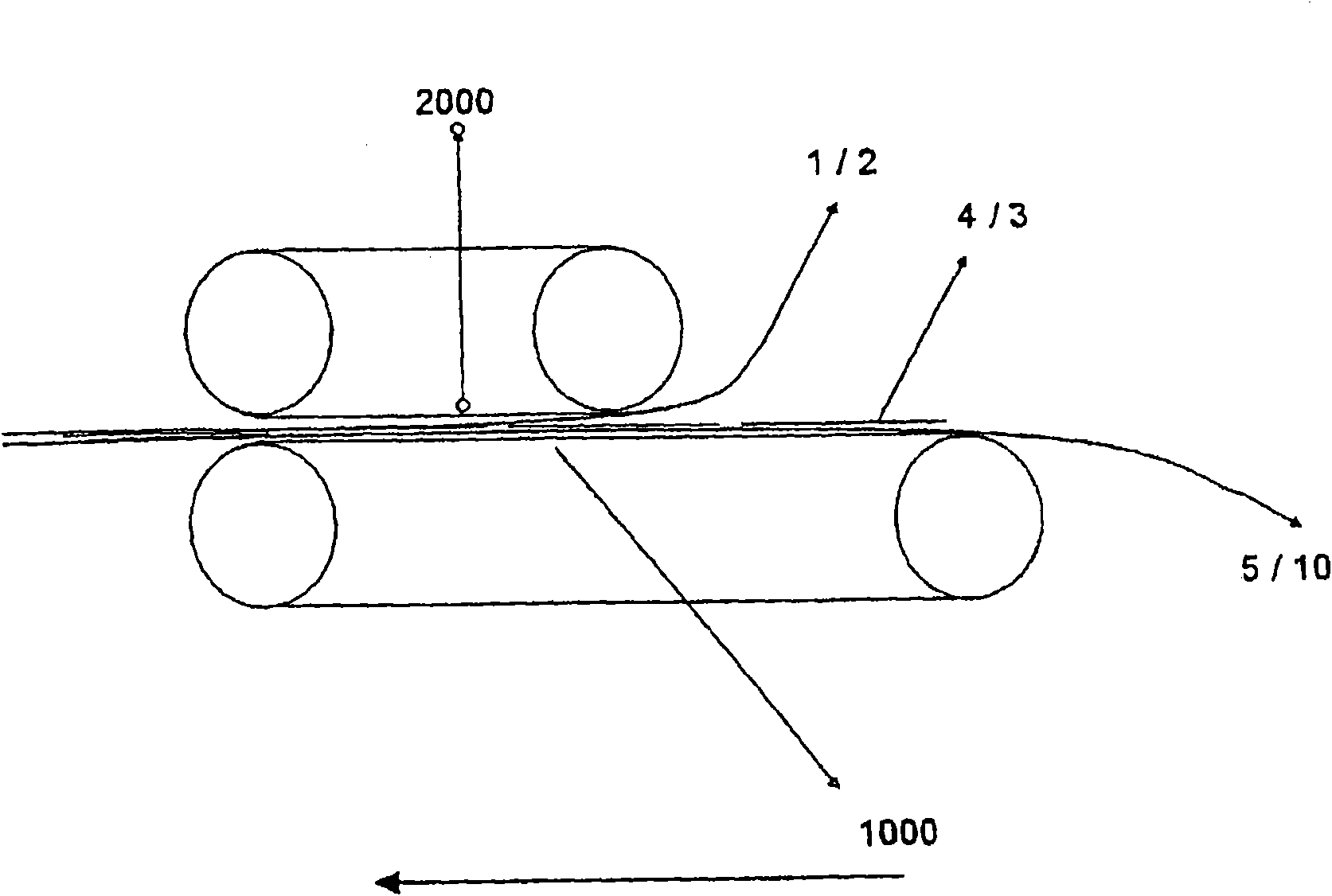

Method used

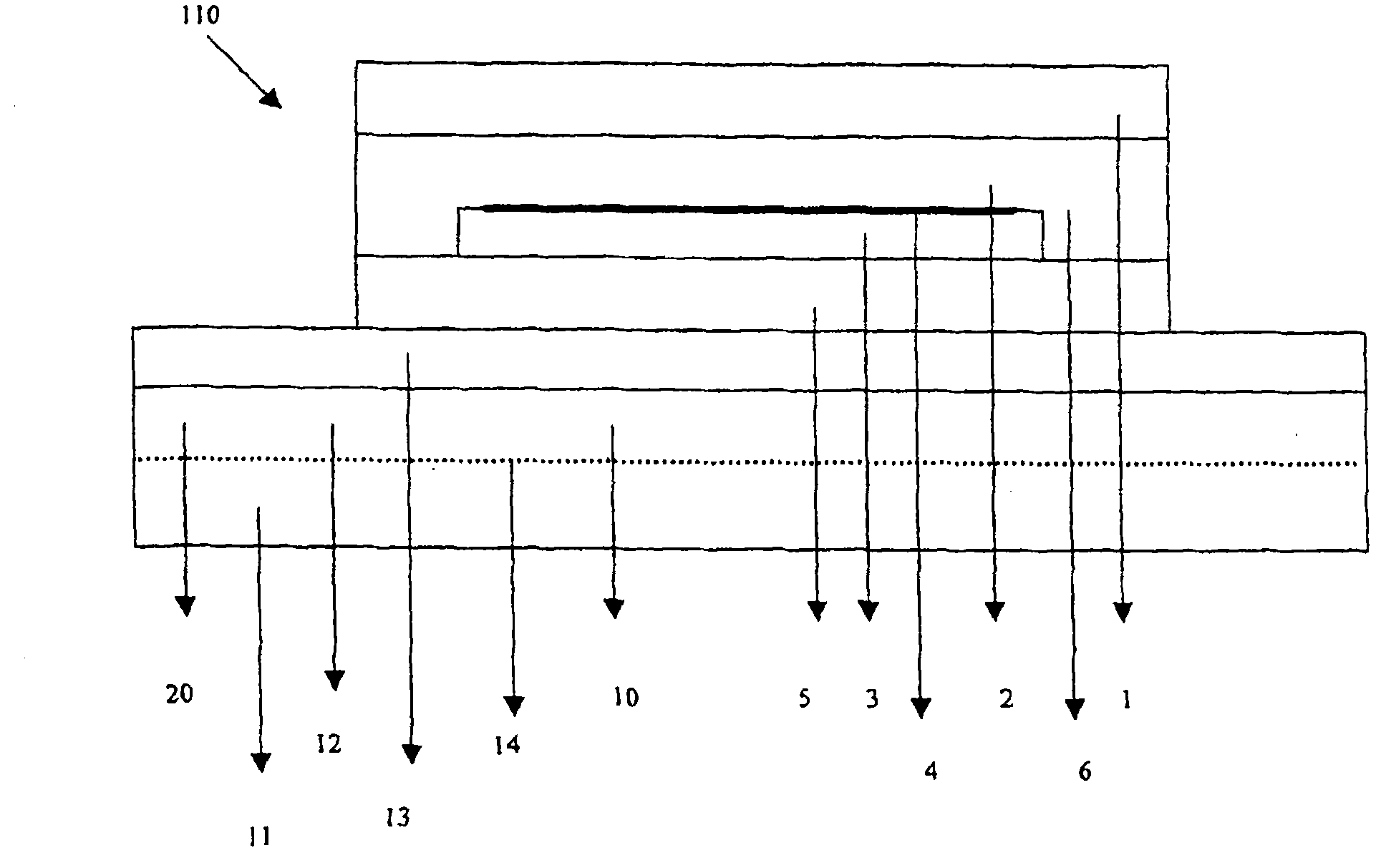

Image

Examples

Embodiment approach 1

[0152] Embodiment 1: Components with Metal Substrates - Demonstrating Bonding Quality, Durability, Electrical Safety and Fire Safety:

[0153] A module M3 is produced by known lamination methods, for example according to EP 0769818 A2, which comprises the following layer stack:

[0154] a) 50 μm ETFE membrane from Dupont (surface treated to attach to EVA)

[0155] b) Two EVA Vistasolar 486.10 membranes (thickness + / - 460μm) stacked

[0156] c) 50 μm PEN film supporting the active layer (e.g. TCO / pin / back electrode / adhesive layer / adhesive to PEN), and Al at the back side of the PEN film 2 o 3 Coating (reactive sputtering)

[0157] d) Coextruded film of "50 μm EAA Primacor 1410 / 900 μm VLDPE Exact 0203 / 50 μm EAA Primacor 1410" containing (average value, not added to all layers to avoid neutralization of acrylic functional groups) antioxidant (0.3% from Ciba Irganox B225), HALS (0.3% Tinuvin 770 and 0.3% Chimassorb 944), acid scavengers, pigments (5% TiO 2 Kronos 2220), 24% ...

Embodiment approach 2

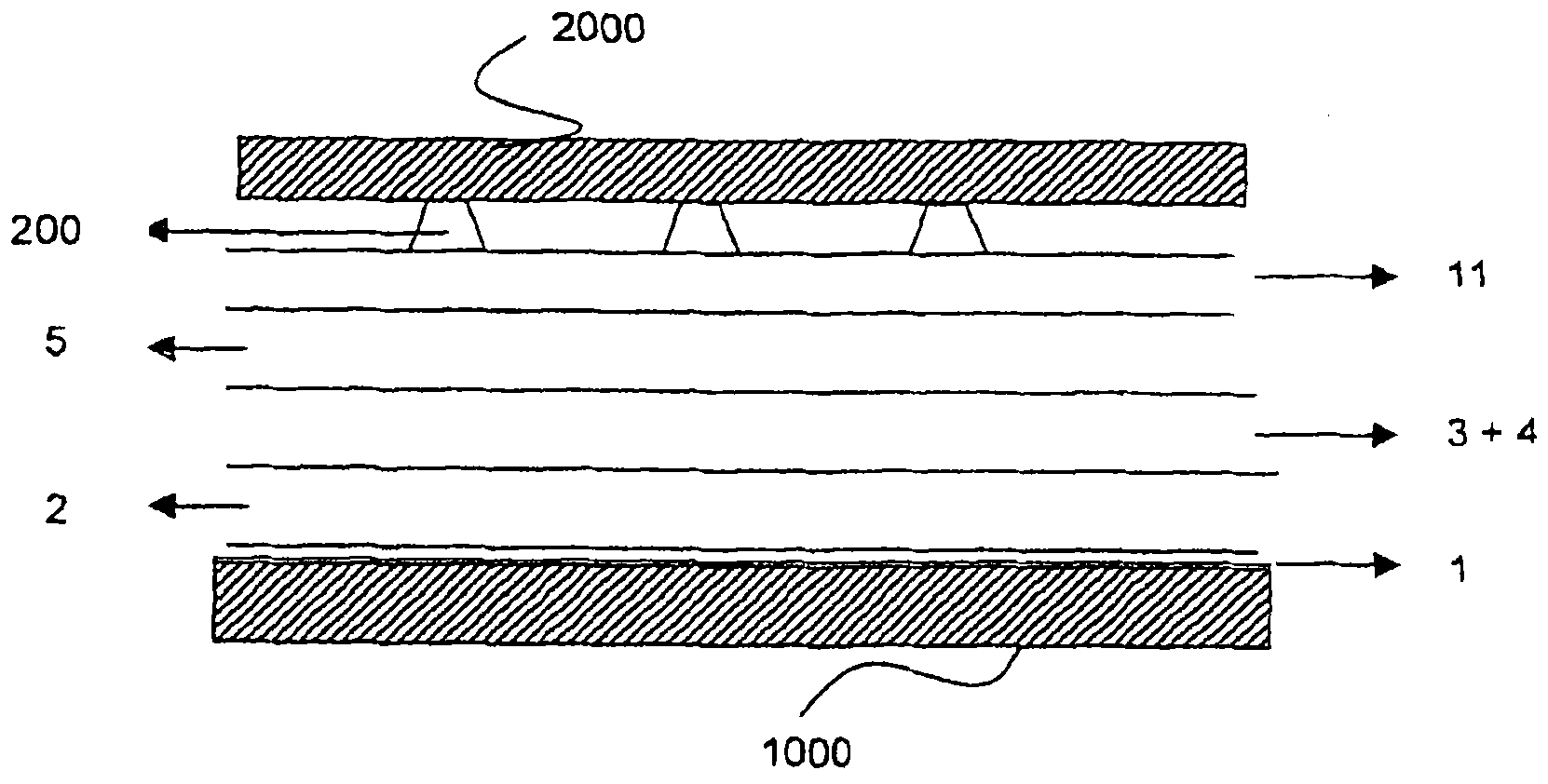

[0167] Embodiment 2: Demonstration of fire-resistant safety of TPO water-resistant membrane (10) and plastic PV cell (110)

Embodiment 1

[0169] Sample A is a polyester reinforced 1.5mm multilayer TPO water resistant membrane (10) according to the invention with a halogenated flame retardant. The composition of the multilayer diaphragm is as follows:

[0170] - Top layer of 300μm Hifax CA 10A with conventional stabilizers and pigments and 25% Saytex BT93 halogenated flame retardant with 10% Sb 2 o 3 .

[0171] - Intermediate layer of 600 μm Hifax CA 10A with conventional stabilizers and pigments and 17% Saytex 8010 halogenated flame retardant with 6% Sb 2 o 3 .

[0172] - 2*21100dTEx polyester reinforcement.

[0173] - Lower layer of 600μm Hifax CA 10A with conventional stabilizers and pigments and 17% Saytex 8010 halogenated flame retardant with 6% Sb 2 o 3 .

[0174] The burnt surface after the fire resistance test is 3200mm 2 .

[0175] Sample B was the same TPO water resistant membrane (10) with the following layer stack laminated on top of it:

[0176] a) 50 μm ETFE, which is surface treated to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com