BIPV photovoltaic module packaging process applying laser additive manufacturing technology

A technology of photovoltaic modules and manufacturing technology, applied in the direction of sustainable manufacturing/processing, photovoltaic power generation, final product manufacturing, etc., which can solve problems such as large influence on photovoltaic module power generation efficiency, application limitations, poor temperature and light control effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

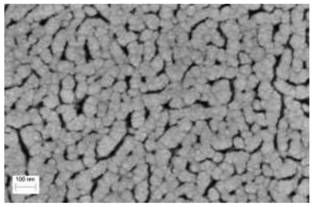

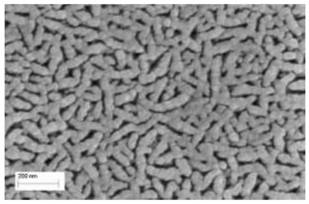

Image

Examples

Embodiment

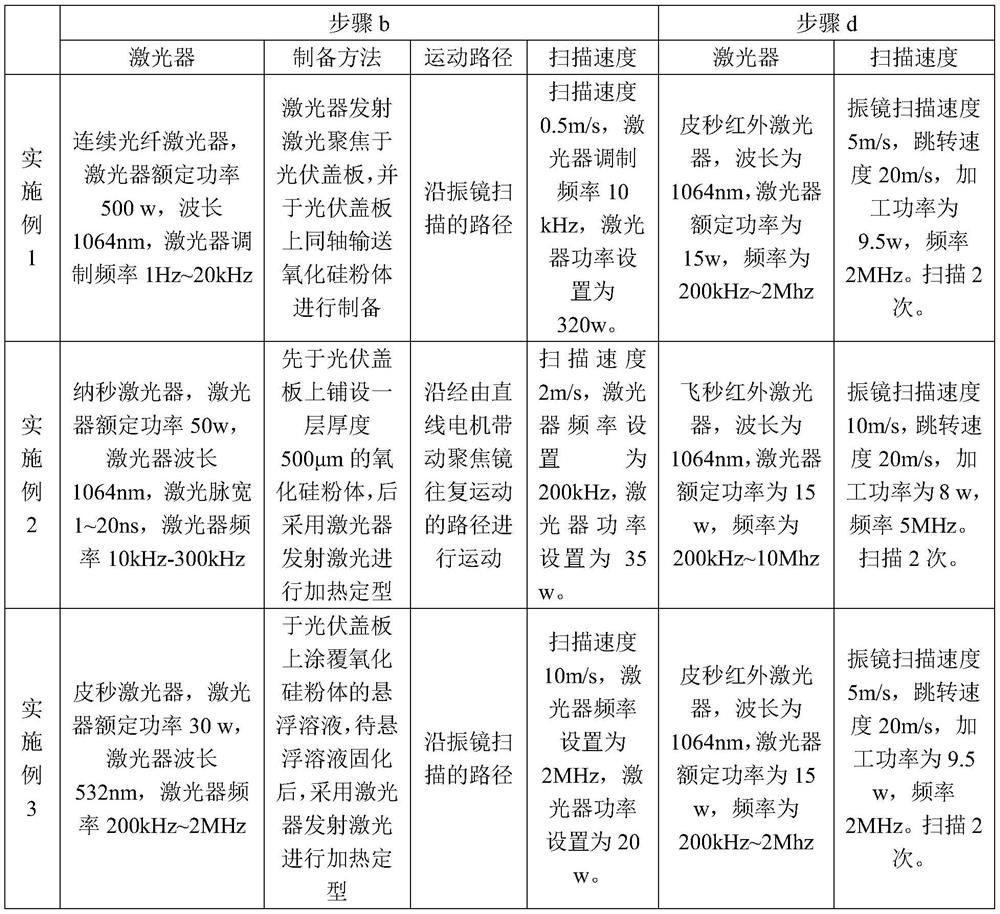

[0032] This embodiment relates to a packaging process for BIPV photovoltaic modules using laser additive manufacturing technology, which specifically includes the following steps:

[0033] a: Use ultrasonic waves, roller brushes or high-pressure water spray to clean the photovoltaic cover, and then use a hot air knife to dry the cleaned photovoltaic cover; the photovoltaic cover can be selected from ultra-white tempered glass, soda-lime glass, borosilicate Glass or stainless steel sheet;

[0034] b: Laser additive manufacturing technology is used to prepare a layer of silicon oxide layer with a certain thickness in the circumferential direction of the photovoltaic cover plate; the thickness of the silicon oxide layer is optimized according to the thickness of the PVB film covered behind, and it is required to be 50-200 μm thicker than the thickness of the PVB film , the thickness needs to be optimized according to the actual shrinkage of PVB; the main component of the silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com